Filter

–

Fiberguide Industries

AFM50/125/250Y Acrylate Coated MM Fiber

300 - 2400 nm; low numerical aperture; Max Operating Temperature 85 °C; Core Diameter 50 µm; Coating Outside Diameter 250 µm

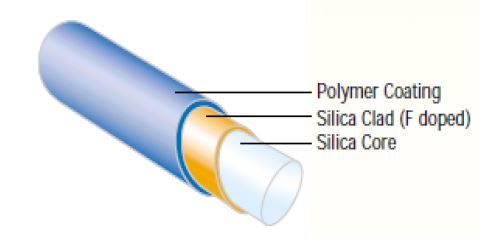

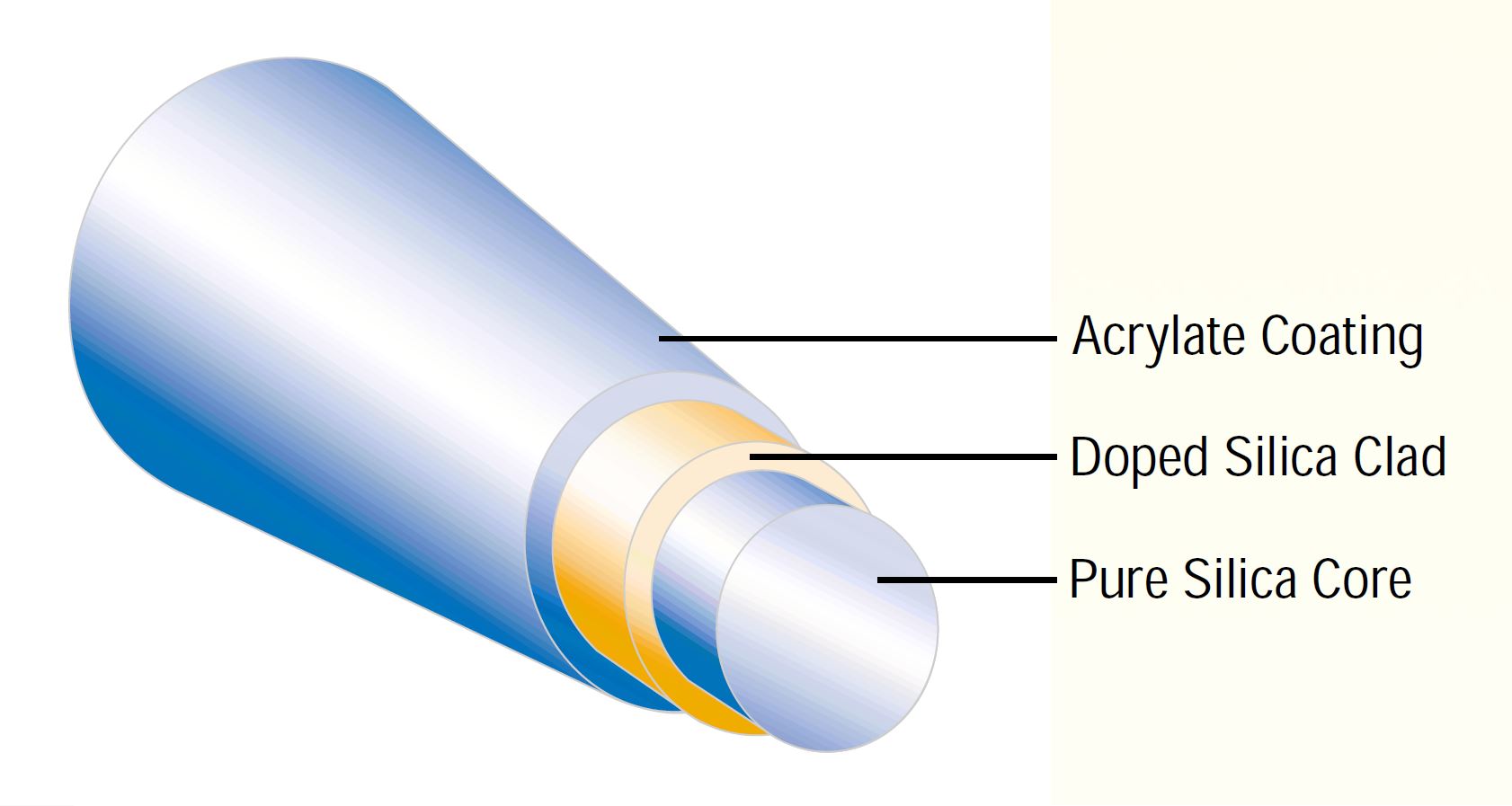

Step Index multi mode fiber with pure fused silica core and fluorine doped silica cladding. With a low concentration of hydroxyl groups (OH), this fiber of the Anhydroguide™ series from Fiberguide Industries is suitable for wavelengths in the visible to infrared domain. It is primarily used in photonics applications where individual or bundled large core (> 50μm) multi mode fibers are needed for the transmission of optical energy.This “AFM” fiber features a low numerical aperture (0.12), resulting in a full acceptance angle of 14°. With a cladding diameter of 140 µm and a silicon buffer coating layer, the minimum bend radius recommended by the supplier is 13 mm (short term) or 25 mm (long term) respectively. The fibers are 100% proof tested using a 4-axis bend method with 100 KPSI. Typical applications are bio-analytical sensing, medical lasers, aerospace/defense, spectroscopy, nuclear plasma sensing or industrial laser systems.

Product number:

C002937-6

Manufacturer:

Fiberguide Industries

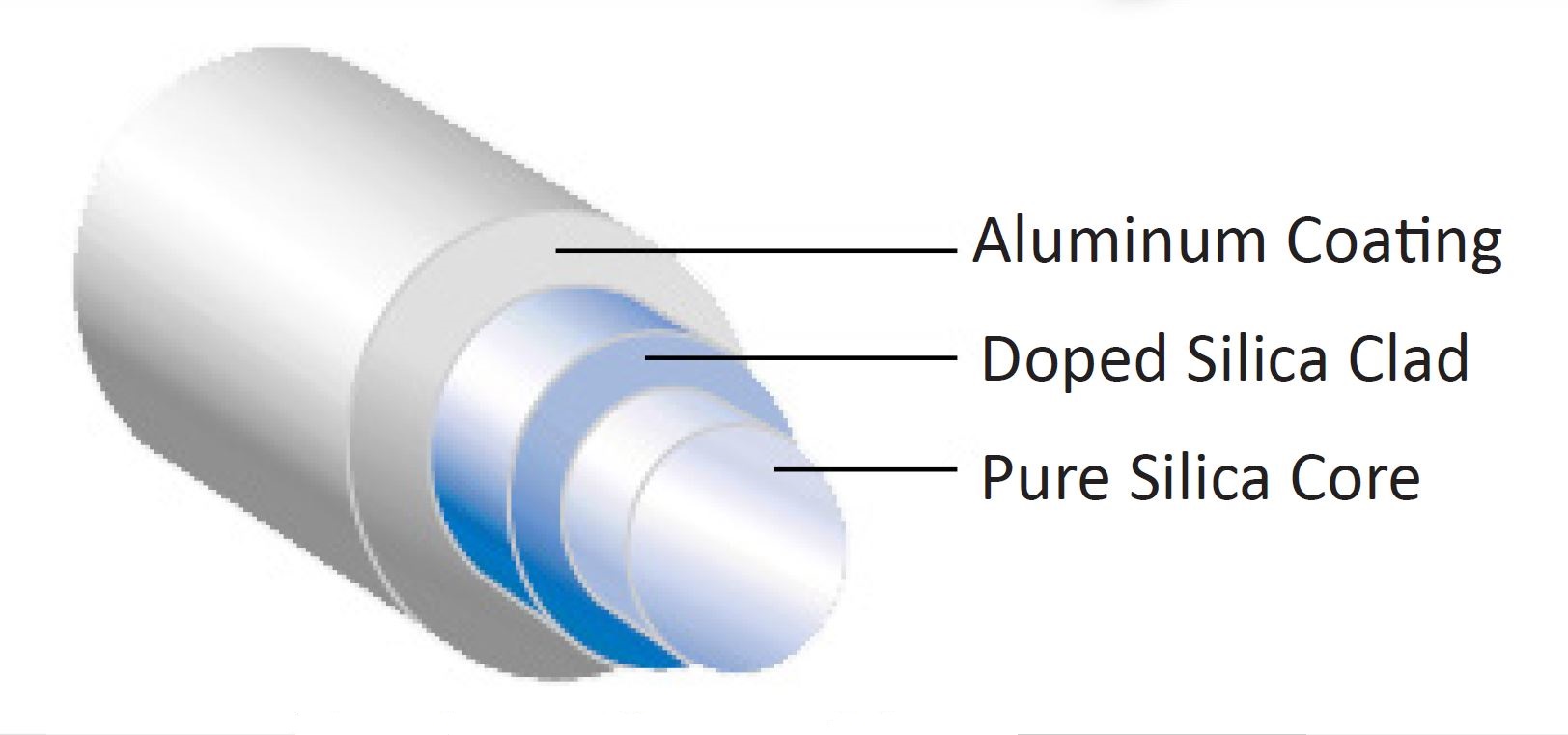

AFS-A/SFS-A/AGI-A/ASI-A/UVS-H2A Aluminium Coated High Temperature Fibers

Aluminium Coated, Single Mode, Multi Mode; 190 to 2400 nm; Core Diameter 50 to 400 µm; Mode Field Diameter 4.3, 9.0 µm; Cladding Diameter 125 to 440 µm; Numerical Aperture 0.12 to 0.275Fiberguide’s AFS-A/SFS-A/AGI-A/ASI-A/UVS-H2A series of aluminium coated fibers are designed for a wide temperature range (-269 to +400 °C) and superior strength (>100 kpsi). This allows for long life at extended stress levels in applications that require tight bends. Also, the strong chemical bond between the silica cladding and the aluminum enables direct termination without pistoning. This bond also makes aluminium coating the ideal choice to preserve deep UV performance in Fiberguide’s Solarguide UVS-H2A series of solarization resistant UV multi mode fiber. Within this series of aluminium coated high temperature fibers, users find step index (AFS/SFS, UVS-H2) and graded index (AGI) multi mode fibers as well as anhydrous silica (ASI) single mode fibers. As an option, some types of aluminium coated high temperature fibers can be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection. Some of the fibers can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Multi Mode (Step/Graded Index) or Single Mode Fibers Pure Fused Silica Core, Fluorine Doped/Pure Silica Cladding Coating: Aluminium Core / Cladding Sizes: 50/125 to 400/440 µm (MM) Mode Field Diameter / Cladding Sizes: 4.3/125, 9.0/125 µm (SM) Numerical Aperture (NA): 0.12 to 0.275 Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter 100% Proof Test Using 4-Axis Bend Method Applications: High Temperature and Cryogenic Temperature Sensing; Semiconductor Manufacturing; Corrosive and Caustic Environments; Ultra-high Vacuum Devices; Radiation Resistant Sensors; Rocket, Turbine and Jet Engine Monitoring

Product number:

SW10693

Manufacturer:

Fiberguide Industries

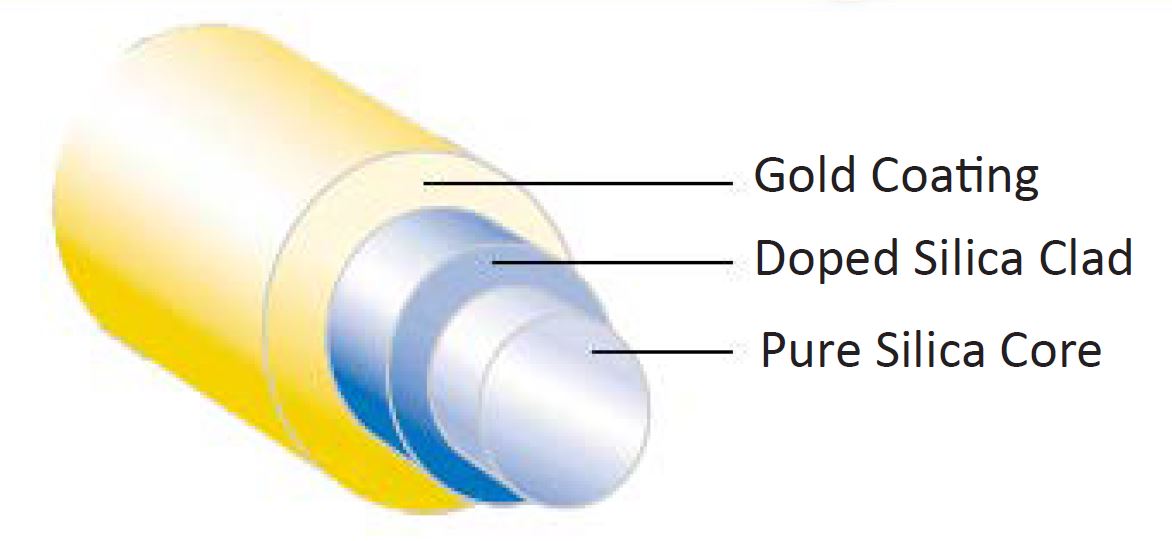

AFS-G/SFS-G/AGI-G/ASI-G Gold Coated High Temperature Fibers

Gold Coated, Single Mode, Multi Mode; 190 to 2400 nm; Core Diameter 50 to 400 µm; Mode Field Diameter 4.3, 9.0 µm; Cladding Diameter 125 to 440 µm; Numerical Aperture 0.12 to 0.275Fiberguide’s AFS-G/SFS-G/AGI-G/ASI-G series of gold coated high temperature optical fibers is designed to achieve the widest temperature range (-269 to +700 °C) of any optical fiber on the market. This, combined with excellent corrosion resistance, and the fiber’s ability to be soldered or brazed, makes it the ideal fiber for many high temperature applications such as turbine flame monitoring, oil and gas down-hole sensing, and high vacuum or pressure applications. As an option, some types of gold coated high temperature fibers can be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection. Some of the fibers can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range.Key Features: Multi Mode (Step/Graded Index) or Single Mode Fibers Pure/Germanium Doped Fused Silica Core, Fluorine Doped/Pure Silica Cladding Coating: Gold Core / Cladding Sizes: 50/125 to 400/440 µm (MM) Mode Field Diameter / Cladding Sizes: 4.3/125, 9.0/125 µm (SM) Numerical Aperture (NA): 0.12 to 0.275 Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter 100% Proof Test Using 4-Axis Bend Method Applications: Turbine Flame Monitoring; Oil and Gas Down-hole Sensing; High Vacuum Applications; High Pressure Applications

Product number:

SW10689

Manufacturer:

Fiberguide Industries

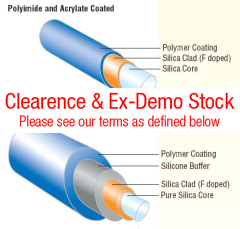

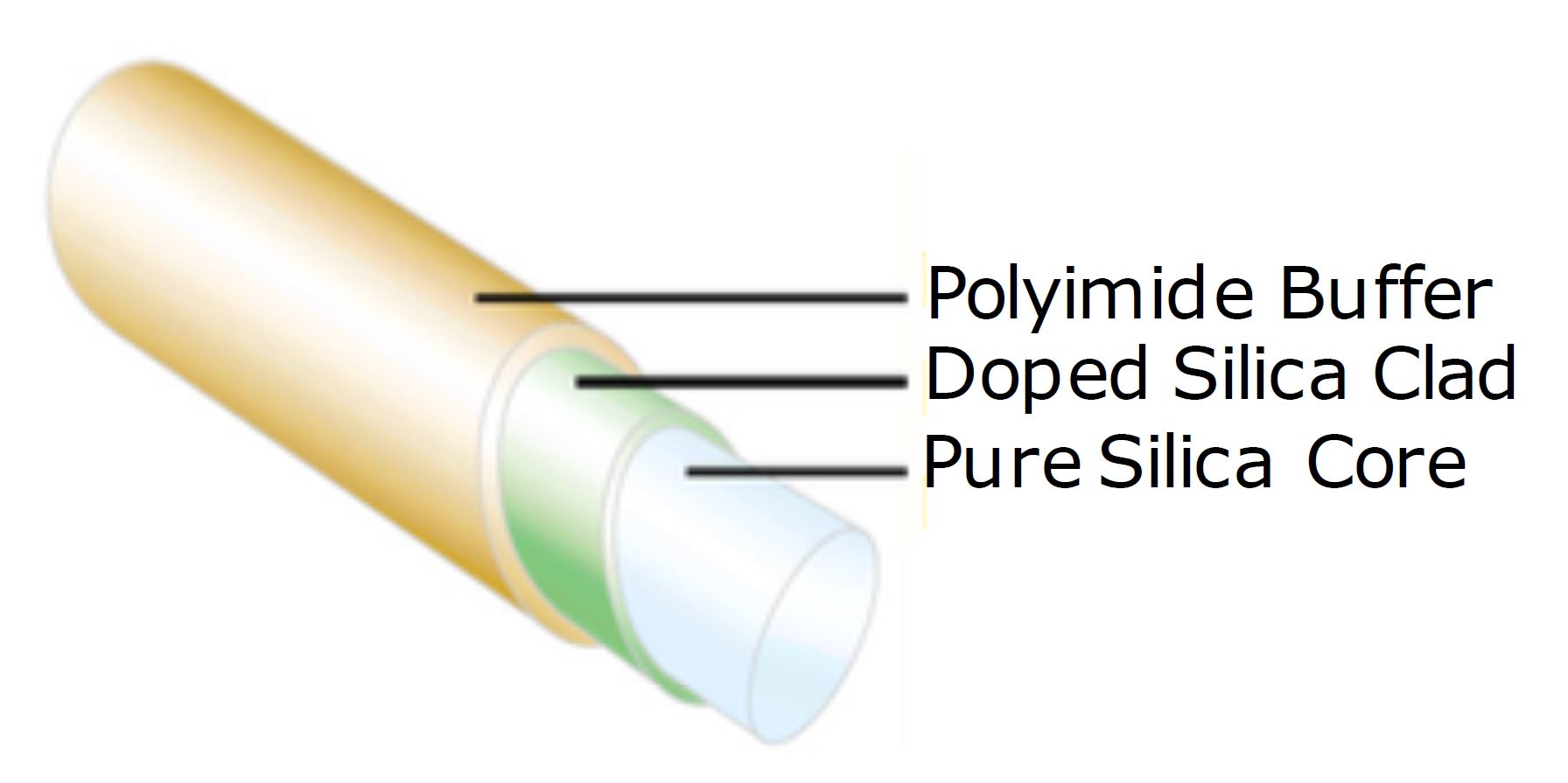

AFS/AFM/AFH/SFS/SFM/SFH All Silica MM Fibers

Multi Mode; 190 to 2400 nm; Core Diameter 50 to 1500 µm; Cladding Diameter 125 to 1650 µm; Coating Acrylate, Polyimide, Nylon, Tefzel, Aluminium, Gold; Numerical Aperture 0.12, 0.22, 0.26Fiberguide’s Anhydroguide™ (AFS/AFM/AFH) and Superguide™ (SFS/SFM/SFH) silica core, silica clad, polymer coated multi mode fibers are primarily used in photonics applications where individual or bundled large core (>50 µm) multi mode fibers are needed for the transmission of optical energy. These fibers can be coated with a variety of polymers or even metalized with aluminium or gold for extreme temperature performance. While the AFS series features a low hydroxyl ion concentration (low OH) and works in the visible to IR range, SFS variants with high hydroxyl ion concentration are suitable for the UV to visible range. Options include Acrylate (-Y), Polyimide (-T), Nylon (-N), Tefzel (-Z), Aluminium (-A) and Gold (-G) coatings as well as standard (AFS/SFS), high (AFH/SFH) and low (AFM/SFM) numerical aperture. As a further option, fibers can also be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection. Some fiber types can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Step Index Multi Mode Fibers Pure Fused Silica Core / Fluorine Doped Silica Cladding Silicone Buffer Coating Layer for Nylon & Tefzel Outer Coatings Coatings Acrylate, Polyimide, Nylon, Tefzel, Aluminium, Gold Core / Cladding Sizes: 50/125 to 1500/1650 µm Wavelengths: SFS (High OH) 190 to 1250 nm; AFS (Low OH) 300 to 2400 nm Numerical Aperture (NA): 0.12, 0.22, 0.26 Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter 100% Proof Test Using 4-Axis Bend Method Available Core/Clad Ratios: 1.1 (Standard), 1.2, 1.4, 2.5 Thermocoat (Polyimide), Nylon, Tefzel certified to NAMSA Class VI Applications: Bio-Analytical Sensing; Medical Laser; Aerospace/Defense; Spectroscopy; Nuclear Plasma Sensing; Industrial Laser Systems

Product number:

SW10692

Manufacturer:

Fiberguide Industries

AFS600/660T Thermocoat Fiberguide

€4.92*

The Anhydroguide™ fiber is drawn from preforms manufactured by the Plasma Outside Deposition (POD) process,

Product number:

C003876-0

Manufacturer:

Fiberguide Industries

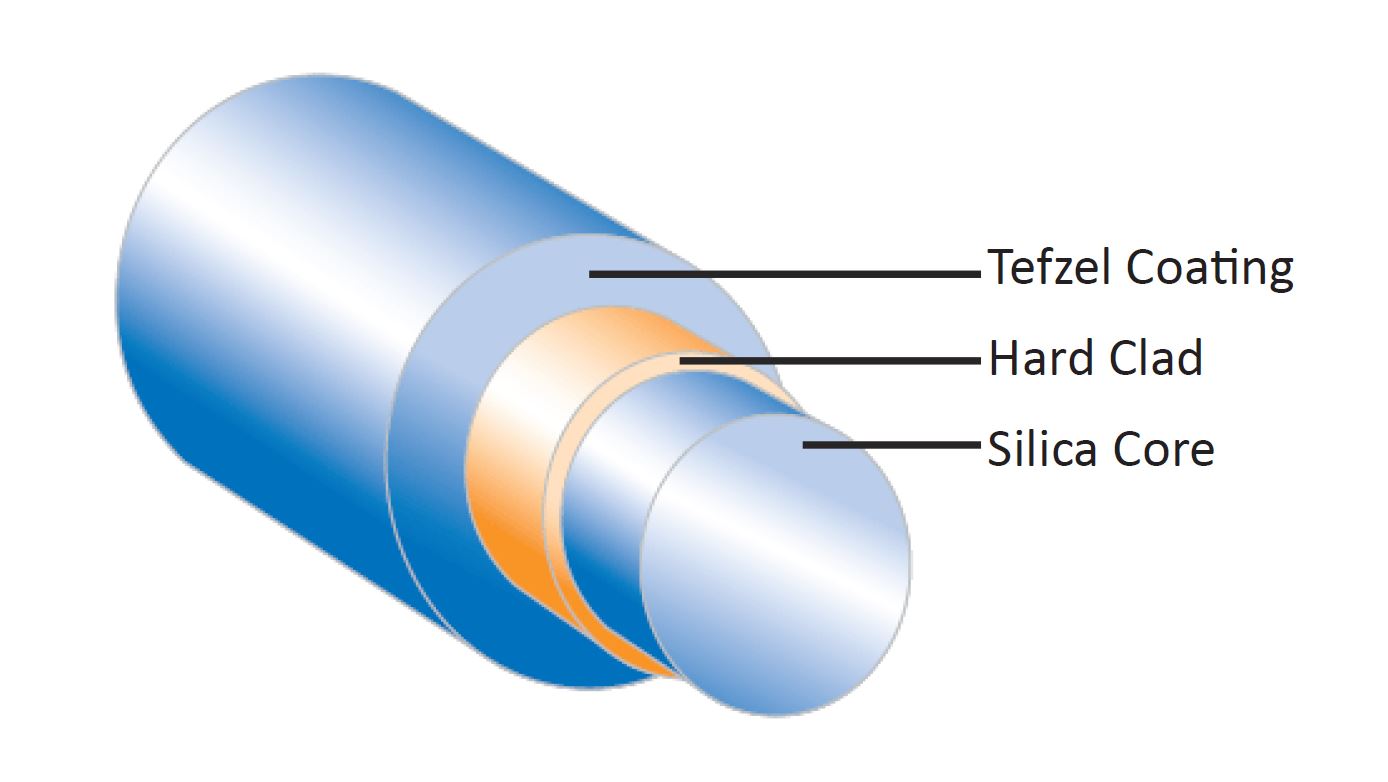

AFSH/SFSH Hard Polymer Coated MM Fibers

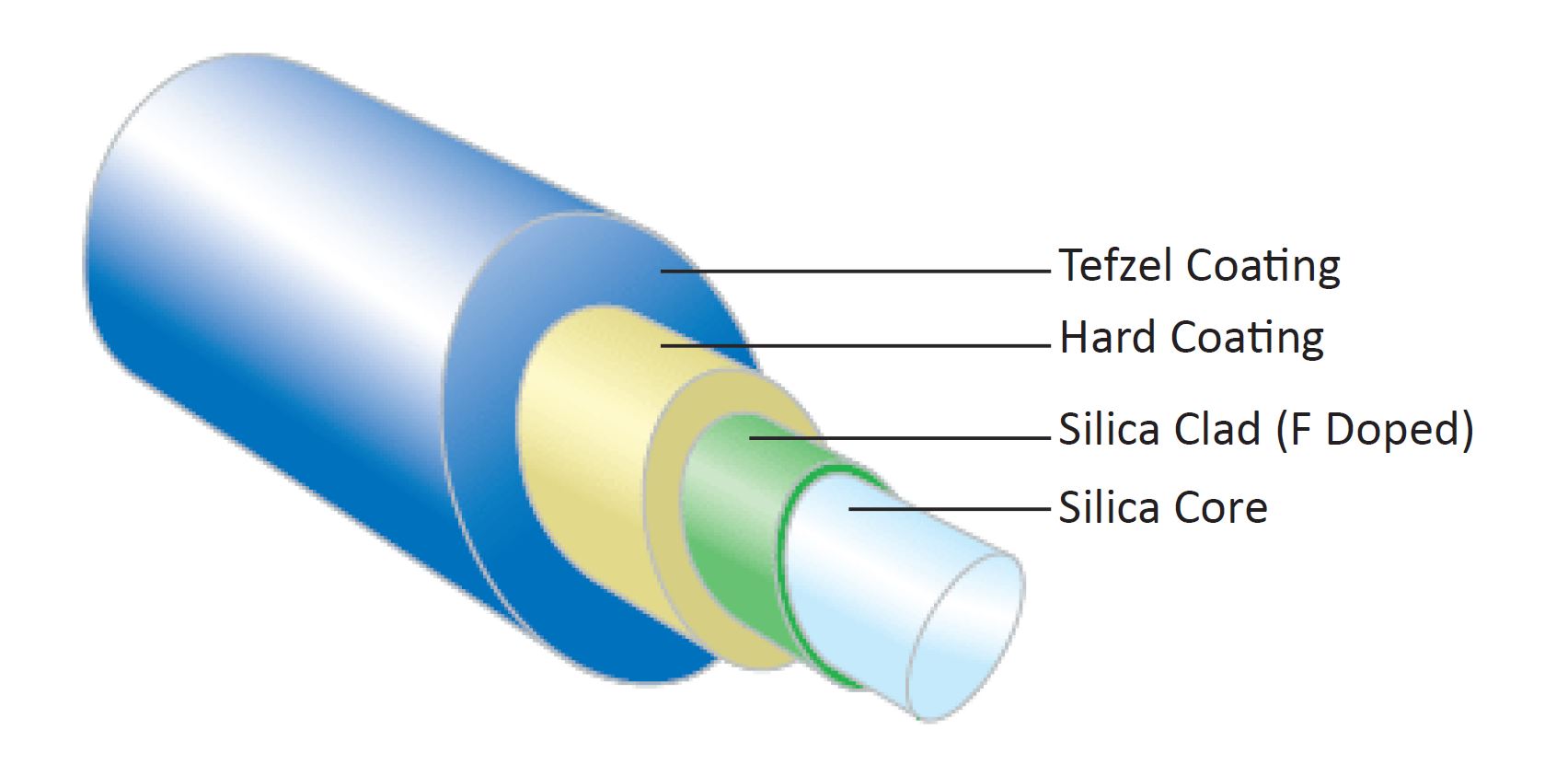

Multi Mode; 190 to 2400 nm; Core Diameter 200 to 900 µm; Cladding Diameter 240 to 1000 µm; Coating Tefzel (Natural & Blue); Numerical Aperture 0.22Fiberguide’s Anhydroguide™ (AFSH) and Superguide™ (SFSH) series of silica core, silica clad, hard polymer coated, polymer outer coated multi mode fibers are similar to Fiberguide’s AFS/AFM/AFH/SFS/SFM/SFH series of silica core, silica clad, polymer coated MM fibers, except there is an added layer of hard polymer on top of the silica cladding. This hard coat serves as stable buffer layer that ensures a sufficient bond between the silica cladding and the polymer outer coating, making these fibers the ideal choice for a variety of medical applications. Other main application areas for the AFSH/SFSH series of hard polymer coated fibers are where individual or bundled large core (>50 µm) multi mode fibers are needed for the transmission of optical energy. While the AFSH series features a low hydroxyl ion concentration (low OH) and works in the visible to IR range, SFSH variants with high hydroxyl ion concentration are suitable for the UV to visible range. Options include natural (-Z) or blue (-C) Tefzel coatings, and fibers can be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection. Some fiber types can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Step Index Multi Mode Fibers Hard Polymer Buffer Coating Layer Coating: Tefzel (Natural or Blue) Core / Cladding Sizes: 200/240 to 910/1000 µm Wavelengths: SFSH (High OH) 19 to 1250 nm; ASFH (Low OH) 300 to 2400 nm Numerical Aperture (NA): 0.22 Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter 100% Proof Test Using 4-Axis Bend Method Tefzel (Natural & Blue) certified to NAMSA Class VI Applications: Bio-Analytical Sensing; Medical Laser; Aerospace/Defense; Spectroscopy; Nuclear Plasma Sensing; Industrial Laser Systems

Product number:

SW10690

Manufacturer:

Fiberguide Industries

AFT/SFT Optical Fiber Tapers

Fiber Type Single Mode, Multi Mode Step & Graded Index; Input Core Diameter 100 to 600 µm; Output Core Diameter 50 to 200 µm; Numerical Aperture 0.12, 0.26; Wavelength 180 to 2400 nm; Sheathing PVC, Stainless SteelFiberguide’s AFT/SFT series of optical tapers are used for mode mixing, lowering optical power density in high power applications, and converting numerical aperture (NA) in optical power delivery applications. Optical tapers can either be tower drawn, where the length is several meters, or they can be produced using bench-top equipment, making the length a few inches. In both cases, these optical tapers are continuous pieces of fiber, they are not spliced. Tapered optical fibers can be made either by fusing a short tapered section onto a longer fixed diameter fiber or by very carefully controlling the drawing process to produce a single continuous fiber with an integral tapered section. For its AFT/SFT series, Fiberguide uses the latter process since it results in superior fiber strength, alignment precision and optical power transmission. Tapered optical fibers cause optical mode mixing that tends to homogenize spatial power distribution. A larger input core diameter can prevent input damage and allow a smaller diameter pigtail for convenience in adapting to a wide range of optical applications. Tapered optical fibers can be used as a passive optical component to alter the input and / or output divergence (N.A.) with regard to an optical fiber, as a high power coupler for laser energy, as this will spread the energy over a larger area, or simply as a device to relax tolerances in an optical system. To ensure maximum efficiency of light transmission, the numerical aperture (N.A.) of the light entering the taper input should be 0.22 divided by the taper ratio. As an example, assume the input core diameter of the taper is 400 µm and the output core is 200 µm (2:1 taper ratio), then the N.A. of the light entering the taper will be 0.22/2 = 0.11.Additionally, the fibers can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Fiber Type: Single Mode, Multimode Input Core Sizes: 100 to 600 µm Wavelengths: 190 to 1250 (High OH), 300 to 2400 nm (Low OH ) Numerical Aperture (NA): 0.12, 0.22, 0.26 Input-to-Output Ratios: Up to 3:1 Connector Options: SMA905 Sheathing Options: PVC Tubing, Stainless Steel Monocoil (Tower Drawn Tapers), Rigid Stainless Steel Tubing (Micro Tapers) Coating: Acrylate Length: Minimum Taper Length 2 m, Overall Length <50 m (Tower Drawn Tapers), ~ 6 inches Typical (Micro Tapers) Applications: Laser Marking, Welding, Soldering; Fluid Level Sensors; Laser Surgery, Angioplasty, Lithotripsy; Non-linear Optics; Diode Laser Array Coupling; Spectroscopy; Analytical Instruments; Laser Delivery; Biosensors; Near-field Scanning Optical Microscopy\Raman and IR Spectroscopy; Humidity Sensing; Delivery Systems for Laser Diodes; High-power Laser Transmittance; Dynamic Position Sensing; Fluorescent Detection

Product number:

SW10706

Manufacturer:

Fiberguide Industries

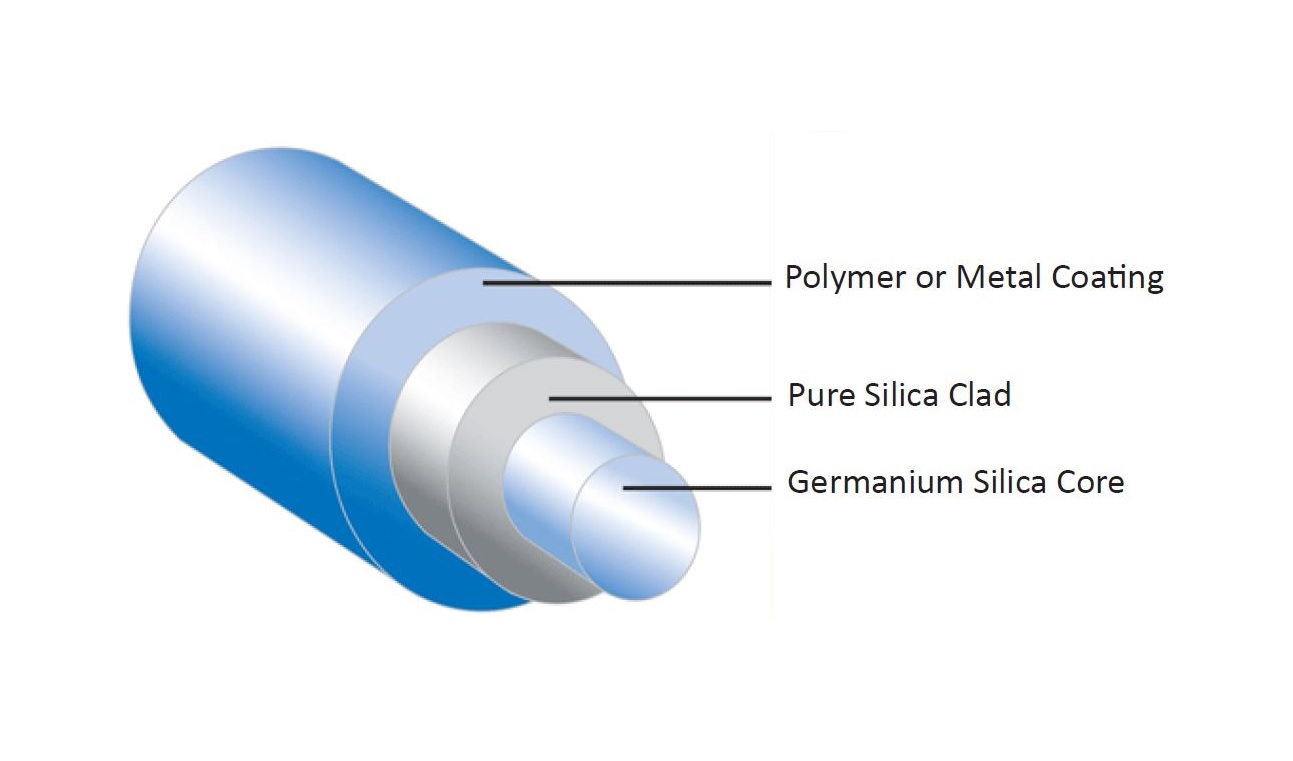

AGI Graded Index MM Fibers

Multi Mode, Graded Index; 850, 1300 nm; Core Diameter 50, 62.5 µm; Cladding Diameter 125 µm; Coating Acrylate, Polyimide, Aluminium, Gold; Numerical Aperture 0.20, 0.275Fiberguide’s AGI series of anhydrous graded index multi mode silica core, silica clad, polymer or metal coated fibers feature a graded index profile instead of a step index profile. These fibers are primarily used in data transmission applications where more bandwidth is needed than step index fibers can offer. These fibers are available with acrylate coatings (-Y) and also high performance polyimide (-T), aluminum (-A) and gold (-G) coatings that allow them to exceed the temperature performance levels of standard fibers. As a further option, AGI series fibers can be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection. AGI series fibers can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Graded Index Multi Mode Fibers Germanium Doped Fused Silica Core / Pure Fused Silica Cladding Coatings: Acrylate, Polyimide, Aluminium, Gold Core / Cladding Sizes: 50/125µm, 62.5/125µm Wavelengths: Optimized for 850nm & 1300nm Numerical Aperture (NA): 0.20, 0.275 Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter 100% Proof Test Using 4-Axis Bend Method Applications: Data Communications; Laser Systems; Medical Applications; Oil & Gas Down-Hole Sensing; Photonic Devices; Optical Sensor Systems

Product number:

SW10180

Manufacturer:

Fiberguide Industries

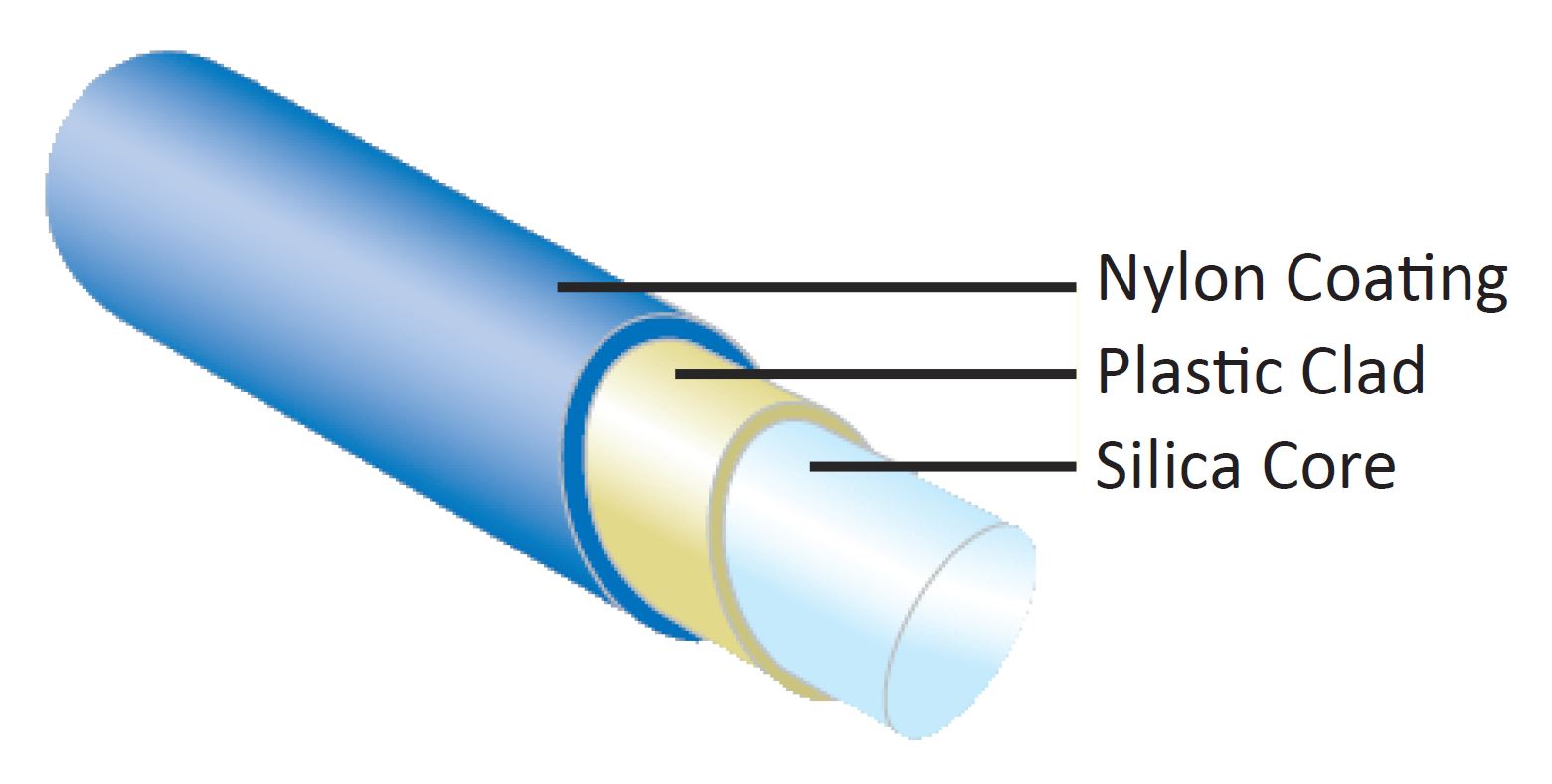

APC/SPC Polymer Clad MM Fibers

Multi Mode; 190 to 2200 nm; Core Diameter 200 to 2000 µm; Cladding Diameter 300 to 2150 µm; Coating Nylon; Numerical Aperture 0.37Fiberguide’s Anhydroguide™ (APC) and Superguide™ (SPC) series of silica core, polymer clad, Nylon coated multi mode fibers feature a polymer cladding. This polymer cladding enables a numerical aperture (NA) of 0.37, but it differs from the hard polymer cladding of Fiberguide’s APCH/SPCH series of hard polymer clad MM fibers because the polymer cladding offers better radiation stability for nuclear research and sensing applications. While the APC series features a low hydroxyl ion concentration (low OH) and works in the visible to IR range, SPC variants with high hydroxyl ion concentration are suitable for the UV to visible range. Both series are coated with NAMSA Class VI Nylon. As an option, fibers can be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection. Some fiber types can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Step Index Multi Mode Fibers Pure Fused Silica Core / Polymer Cladding Coating: Nylon Core / Cladding Sizes: 200/300 to 2000/2150 µm Wavelengths: SPC (High OH) 190 to 1250 nm, APC (Low OH) 400 to 2200 nm Numerical Aperture (NA): 0.37 Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter 100% Proof Test Using 4-Axis Bend Method Nylon certified to NAMSA Class VI Applications: Bio-Analytical Sensing; Medical Laser; Dental Curing; Spectroscopy; Nuclear Plasma Sensing; Photodynamic Therapy

Product number:

SW10691

Manufacturer:

Fiberguide Industries

APCH/SPCH Hard Polymer Clad MM Fibers

Multi Mode; 190 to 2200 nm; Core Diameter 200 to 1500 µm; Cladding Diameter 230 to 1550 µm; Coating Tefzel (Natural & Blue); Numerical Aperture 0.37Fiberguide’s Anhydroguide™ (APCH) and Superguide™ (SPCH) series of silica core, hard clad fibers feature a hard polymer cladding instead of a silica cladding. This hard polymer cladding enables a higher numerical aperture (NA, 0.37) than a silica cladding and reduces cost. Hard clad fibers like the APCH/SPCH series are the ideal choice for disposable medical products. While the APCH series features a low hydroxyl ion concentration (low OH) and works in the visible to IR range, SPCH variants with high hydroxyl ion concentration are suitable for the UV to visible range. Options include natural (-Z) or blue (-C) Tefzel coatings. As an option, fibers can be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection. Some fiber types can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Step Index Multi Mode Fibers Pure Fused Silica Core / Hard Polymer Cladding Coating: Tefzel (Natural or Blue) Core / Cladding Sizes: 200/230 to 1500/1550 µm Wavelengths: SPCH (High OH) 190 to 1250 nm, APCH (Low OH) 400 to 2200 nm Numerical Aperture (NA): 0.37 Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter 100% Proof Test Using 4-Axis Bend Method Tefzel (Natural & Blue) certified to NAMSA Class VI Applications: Bio-Analytical Sensing; Medical Laser; Dental Curing; Spectroscopy; Nuclear Plasma Sensing; Photodynamic Therapy

Product number:

SW10700

Manufacturer:

Fiberguide Industries

ASI Anhydrous Silica SM Fibers

Single Mode; 633 to 680, 1310 nm; Mode Field Diameter 4.3, 9.0 µm; Cladding Diameter 125 µm; Coating Acrylate, Polyimide, Aluminium, Gold; Numerical Aperture 0.12Fiberguide’s ASI series of silica core, silica clad, polymer or metal coated single mode fibers is used in data transmission applications as well as photonics applications where a single optical path, or mode, is desired. The ASI fiber series is available with acrylate (-Y) coatings and also high performance Polyimide (-T), aluminium (-A), and gold (-G) coatings that allow these fibers to exceed the temperature performance levels of standard fibers. Additionally, the ASI series fibers can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Single Mode Fibers Germanium Doped Fused Silica Core / Pure Fused Silica Cladding Mode Field Diameter / Cladding Sizes: 4.3/125 µm, 9.0/125 µm Wavelengths: 633 to 680 nm (4.3/125 µm), 1310 nm (9.0/125 µm) Numerical Aperture (NA): 0.12 Coatings: Acrylate, Polyimide, Aluminium, Gold Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter 100% Proof Test Using 4-Axis Bend Method Applications: Data Communications; Laser Systems; Medical Applications; Oil & Gas Down-Hole Sensing; Photonic Devices; Optical Sensor Systems

Product number:

SW10704

Manufacturer:

Fiberguide Industries

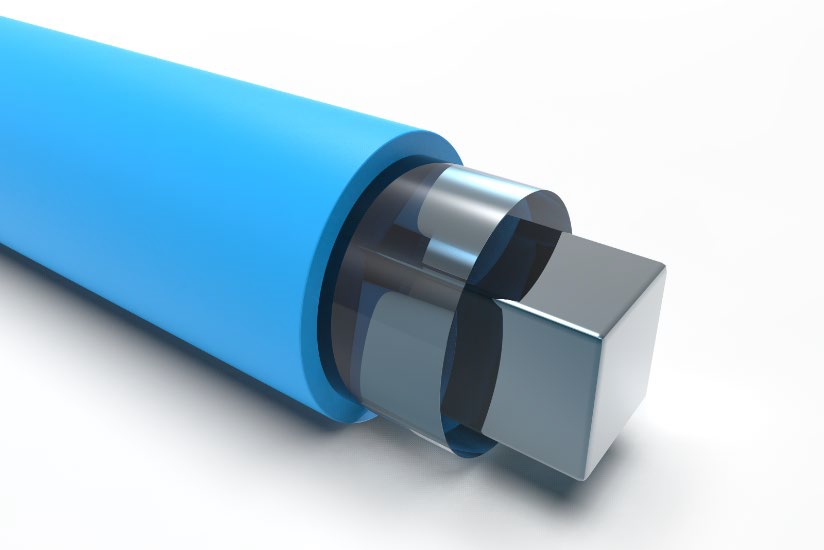

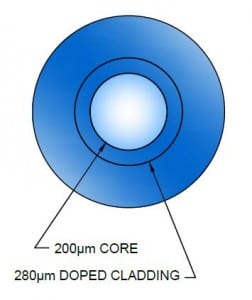

ASQR/SSQR Square Core MM Fibers

Multi Mode, Square Core; 190 to 2400 nm; Core Size 100 to 1000 µm; Coating Acrylate, Nylon, Polyimide; Numerical Aperture 0.22Fiberguide’s Anhydroguide™ (ASQR) and Superguide™ (SSQR) series of square silica core, doped round cladding multi mode optical fibers excel in specific applications where traditional circular core fibers with Gaussian outputs are not ideal. The uniform “top hat” intensity profile these fibers provide are the desired output profile when performing tasks such as welding, photolithography, and spectroscopy. Square core fibers with round claddings are also excellent candidates for use in the laser diode industry, where the square shape enables a more ideal coupling match with the diode source. Fiberguide offers pure silica square core fibers with a fluorine doped cladding (0.22 NA) in a wide range of core diameters from 100 μm to 1000 μm. While the ASQR series features a low hydroxyl ion concentration (low OH) and works in the visible to IR range, SSQR variants with high hydroxyl ion concentration are suitable for the UV to visible range. Options include Acrylate, Polyimide and Nylon coatings as well as anti-reflective coatings like standard thin film coatings or RARe Motheye nano-surfacing. This anti-reflective technology enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Homogenized Output Distribution Top Hat Beam Profile Greater Capture Area than Round Fibers for Square Inputs Step Index Multi Mode Fibers Square Silica Core / Doped Round Cladding Coatings: Acrylate, Nylon, Polyimide Core Sizes: 100 to 1000 µm Typical Clad/Core Ratio (RD Clad): 1.2 (Diagonal to Clad OD) Wavelengths: SSQR (High OH) 190 to 1250 nm, ASQR (Low OH) 300 to 2400 nm Numerical Aperture (NA): 0.22 ±0.02 100% Proof Test Using 4-Axis Bend Method Applications: Laser Materials Processing; Astronomical Spectroscopy; Non-circular Diode Beam Coupling; Photolithography

Product number:

SW10701

Manufacturer:

Fiberguide Industries

Bundled Assemblies

Fiber optic assemblies range from a single fiber cable terminated with industry standard connectors on both ends and jacketed in flexible sheathing, to a multi-fiber design consisting of multiple inputs and/or outputs, each with different cross-section areas and geometries, each requiring a custom machined endfitting and a heavy duty outer jacket to protect the assembly from being crushed. Fiberguide designs and engineers assemblies using not only Fiberguide’s own pure silica core / silica clad, silica core / plastic clad fibers, but borosilicate glass fiber, ESKA™ plastic optical fiber, fluoride fiber, chalcogenide fiber, erbium-doped fiber and polarization maintaining fiber as well. Fiberguide’s bundled assemblies are available with numerical apertures from 0.12 to 0.66, with the widest range of custom and standard endfittings / connectors and outer jackets to tailor a product to your technical and economic requisites. For high temperature applications, some fiber types can be aluminium or gold coated on request. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. As an option, some fiber types can be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size but can be easily customized for a variety of fiber types and specialized applications. For the full range of design features available please download the data sheet. And for your custom bundled assembly, please contact AMS Technologies – our staff of engineers and technical sales professionals unites with Fiberguide’s experienced design and production team in developing a solution specific to your project’s individual requirements. Key Features: Configurations: Multifiber Fiber Type: All of the Fibers in Fiberguide’s Optical Fiber Product Line Connectors: Custom Machined Ferrules (Round, Square, Rectangular, Slit), SMA, FC, ST, etc. Sheathing: Wide Variety of Polymer & Metal Tubing and Monocoil Can be Designed With Multiple Fiber Types, Multiple Splits / Divisions, Custom Leg Lengths, etc. Standard Temperature Range: -40° to +100 °C, Extended Range -269 to +750 °C Vacuum Compatible Tested to 10-9 Torr Chemical Resistant: Acids, Bases and Organic Solvents Radiation Resistant (Gamma, E-Beam, Fast Neutrons, X-Ray) Operating Wavelengths 180 to 2400 nm Overall Lengths up to 100 m Applications: Colorimetry; Spectroscopy; Laser Cutting; Chemical Analysis; Laser Welding; Proteomics; Photodynamic Therapy; Medical Laser; Surface Profile; Test & Measurement; Inspection Systems, Airborne Flight Applications; Fluorescence Microscopy

Product number:

SW10697

Manufacturer:

Fiberguide Industries

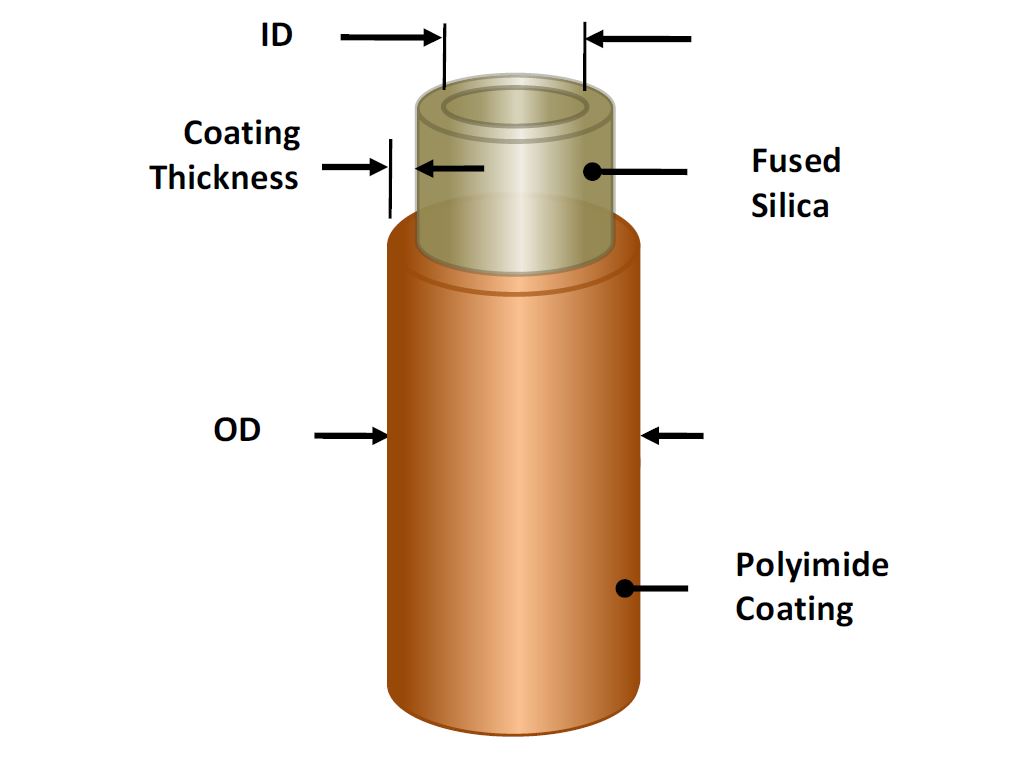

CAP Fused Silica Capillary Tubing

Inside Diameter 15 to 450 µm; Outside Diameter 90 to 673 µm; Coating Polyimide; Temperature Range -190 to +350 °C; Tensile Strength >600 kpsi

Fiberguide’s fused silica capillary tubing is used for micro-fluidics applications and in gas chromatography (GC) separation columns. These capillaries are coated with polyimide for mechanical stability and versatile uses. With inert surfaces and high purity, Fiberguide’s capillary tubing solutions provide a very high phase stability, while their peak mechanical stability leads to greater yield and more cost-efficient tubing. Based on the great flexibility combined with high tensile strength (>600 kpsi), these capillary tubing solutions are pressure resistant to 4,500 psi and allow very small radii during coiling with no kinking. They are impervious to chemicals, allowing usage in harsh environments. A wide range of internal and external diameters with tight tolerances allows users to select a capillary tubing solution that best suits their flow rate requirements. All capillaries can be easily cleaved or cut, allowing to adjust exactly the column length needed for interfacing. While the mirror smooth inner surface provides stable laminar flow profiles and good adherence, the capillary tubing solutions’ Polyimide coating is very durable and abrasion resistant. Key Features:

Pure Fused Silica Construction

Outside Diameters: 90 to 673 µm

Inside Diameters: 15 to 450 µm

Coating: Polyimide

Temperature Range: -190 to +350 °C

Tensile Strength: >600 kpsi

100% Proof Tested for Strength

Applications: Micro-fluidics Applications; Gas Chromatography (GC) Separation Columns

Product number:

SW10708

Manufacturer:

Fiberguide Industries

COL005/COL012/COL025, FSG012/FSG025 Receptacle Style Collimators & Focusers

Collimators and Screw-on Focusers; Wavelength UV to IR; Focal Length 10 mm to 76 mm; Single Mode & Multi Mode Fibers, Connector Options SMA905, FC, ST

Fiberguide’s Collimators and Focus Guides are for use in a wide variety of optical systems. These ruggedized modules are designed to collimate or focus light exiting an optical fiber to a desired beam diameter or spot size a specific distance away. Collimators and Focus Guides are used with laser diodes, photodiodes, acoustic-optic modulators and other fiber optic devices where a specific output is needed.

Key Features:

Collimator Focal Lengths: Micro (10 mm), Mid-Size (18 mm), Macro (38 mm)

Focus Guide Focal Lengths: Mid-Size (18 mm, 25 mm, 38 mm), Macro (38 mm, 51 mm, 76 mm)

Fiber Type: Single Mode, Multi Mode

Core Sizes: < 1000 µm

Wavelengths: UV – IR: 190 nm – 2400 nm

Numerical Aperture (NA): 0.12, 0.22, 0.26, 0.37

Lens Materials: BK-7, Silica

Connector Options: SMA905, FC, ST

Standard Temperature Range: -40° C to +100° C / -40° F to +212° F

Product number:

SW10212

Manufacturer:

Fiberguide Industries

De-Specklers

Wavelength 400 to 1550 nm; Fiber Types All Silica, Plastic Clad, Round or Square Core; Fiber Core Size 100 to 400 µm; Buffer Types Polyimide, Nylon, Tefzel, Acrylate; Power Supply 5 V

Fiberguide’s proprietary de-speckler technology averages the modal noise within an optical fiber. This reduction in speckle is an ideal choice for fiber assemblies used in the life sciences, digital laser projection, interferometry, laser beam homogenization, lithography and metrology. For many fiber coupled applications, modal noise interferes with optimal performance. Fiberguide has developed a small and compact de-speckling system which maximizes performance and reliability. Key Features:

Wavelength: 400 to 1550 nm

Assembly Types: Single Fiber Assemblies

Fiber Types: All Silica, Plastic Clad, Round or Square Core

Fiber Core Size 100 to 400 µm

Buffer Types: Polyimide, Nylon, Tefzel, Acrylate

Connectors: 905/906 SMA, FC/PC,UPC,APC, ST/PC,UPC,APC, Cleaved/Polished Ends, Round 2.5 mm Ferrule, Custom

50 x 22.25 x 13.3 mm

Power Supply 5 V

Power Consumption 3 W

Applications: Bioanalytical Instrumentation; Flow Cytometry; Gene Sequencing; Fluorescent Microscopy; Microscopy; Spectroscopy; Digital Laser Projection; Interferometry; Laser Beam Homogenizers; Lithography; Metrology

Product number:

SW10707

Manufacturer:

Fiberguide Industries

End Capped High Power Assemblies

Fiber Type Step Index MM, Other; Wavelength 190 to 2400 nm; Sheathing Stainless Steel Monocoil (Bare or PVC Coated); Termination High Power SMA, High Power FD-80Fiberguide’s end capped high power fiber optic assemblies allow the user to achieve higher coupled power into a fiber core by reducing the power density at the air/ silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber core sizes but can be easily customized for a variety of fiber types and specialized applications. End capped high power assemblies allow for much higher transmitted powers by reducing the power density to a level below the damage threshold. Their shaped endcap tips can be tailored to specific laser launch conditions and applications. Fiberguide’s proprietary laser polishing process minimizes surface imperfections and maximizes power handling. High Power SMA and D-80 compatible connector options offer superior thermal management while minimizing connector stress for NA conservation. With their epoxy-free cantilevered nose design (available in select versions), Fiberguide’s end capped high power assemblies allow thermal energy to safely dissipate and thus minimize laser and heat damage to surrounding materials Fiberguide offers end capped high power assemblies for a broad range of step index multi mode fibers, including AFS/AFM/AFH/SFS/SFM/SFH all silica optical fiber, AFSH/SFSH hard polymer coat fiber, APC/SPC polymer clad fiber, APCH/SPCH hard clad fiber, AFR/SFR Uniclad™ high power fiber or Solarguide™ solarization resistant fiber. For end capping other fiber types like AGI/ASI anhydrous graded index multi mode fiber or single mode fiber, please get in touch with AMS Technologies’ fiber optic team and discuss the requirements of your solution! For high temperature applications, some fiber types can be aluminium or gold coated on request. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Standard Fiber Type: Step Index Multimode, Other Fiber Types (SM, Graded Index, …) Available Upon Request Core Sizes: 50 to 400 μm Wavelengths: 190 to 1250 (High OH), 300 to 2400 nm (Low OH ) Standard Numerical Aperture: 0.20, 0.22 Connector Options: High Power SMA, High Power FD-80 Sheathing Options: Stainless Steel Monocoil (Bare or PVC Coated) Power Handling Capacity: Up to 3 kW Standard Temperature Range: -40 to +100 °C

Product number:

SW10695

Manufacturer:

Fiberguide Industries

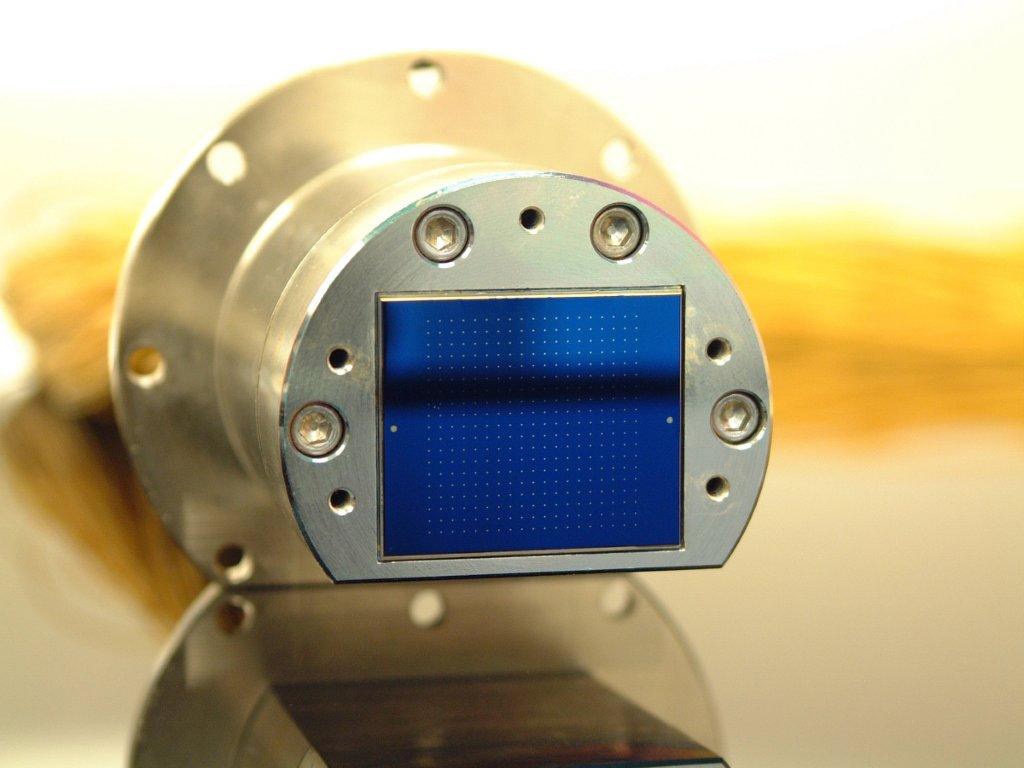

Fiber Arrays & V-Grooves

Fiber Type Single Mode, Multi Mode, Polarization Maintaining (PM/PZ); Number of Fibers ≤128 (V-Grooves), ≤4096 (2D Arrays); Fiber Cladding Outer Ø 125 µm (V-Grooves), 125 to 220 µm (2D Arrays); Connector Options SMA, FC, ST, SC, LC, MTP, etc.Fiberguide produces extremely tight tolerance one-dimensional (V-Grooves) and two-dimensional arrays using the supplier’s patented manufacturing techniques. These arrays range from a few fibers to thousands of fibers depending on the application. Optical Arrays are used in optical switching and in sensing applications where spatial optical data is necessary, such as DNA sequencing, astronomy and nuclear research. For high temperature applications, some fiber types can be aluminium or gold coated on request. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Fiber Type: Single Mode, Multi Mode Array End: Precision Machined Housings, Silica V-Grooves or Custom Silicon Wafers Connector Options: SMA, FC, ST, SC, LC, MTP, etc. Packaging: Design and Production of Custom Array Housings and Sheathing Arrangements Available to Protect the Fiber Depending on the Application Standard Temperature Range: -40 to + 100 °C Applications: Fiber Optic Switch; Signal Processing; Astronomical Analysis; Military Mapping; DNA Micro-array Technology; Optical Tomography

Product number:

SW10696

Manufacturer:

Fiberguide Industries

High Power Laser Assemblies

Fiber Type Step Index MM; Length <100 m; Wavelength 190 to 2400 nm; Sheathing Stainless Steel Monocoil (Bare or PVC Coated); Termination High Power SMA, High Power FD-80, High Power FD-80 with SapphireFiberguide’s high power laser assemblies use Fiberguide’s high power SMA and high power industrial FD-80 connectors to provide a fiber optic link between the laser source and the target. These high power laser assemblies are ideal for laser cutting, welding, drilling, and marking applications. High power SMA and D-80 compatible connectors offer superior thermal management while minimizing connector stress for NA conservation. With their epoxy-free cantilevered nose design, Fiberguide’s high power assemblies allow thermal energy to safely dissipate without burning the surrounding material. Their laser-polished end faces – also available with anti-reflective (AR) coating – maximize power handling capability. When selecting optical cable assemblies for power delivery systems, designers must consider the power limitations of the three main components of the cable assembly: the base material, the input connector, and the mode stripper (if used). Contact the AMS Technologies fiber optic expert team to discuss your project’s requirements and to define and design your customized high power laser assembly! As an option, some fiber types can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Fiber Type: Step Index Multimode Core Sizes: 100 to 1500 μm Wavelengths: 190 to 1250 (High OH), 300 to 2400 nm (Low OH ) Numerical Aperture (NA): 0.20, 0.22 Connector Options (w or w/o Integrated Mode Stripper): High Power SMA, High Power FD-80, High Power FD-80 with Sapphire Sheathing Options: PVC Coated Stainless Steel Monocoil, Bare Stainless Steel Monocoil Power Handling Capacity: 85 to 750 W Standard Temperature Range: -40 to +100 °C Lengths: <100 m Applications: Laser Cutting; Laser Welding; Laser Drilling; Laser Marking

Product number:

SW10703

Manufacturer:

Fiberguide Industries

High Temperature Assemblies

Fiber Type High Temperature Metalized, Single Mode, Multi Mode; Number of Fibers TBD; Length ≤100 m; Wavelength 190 to 2400 nm; Sheathing Aluminium, Gold; Termination Custom Machined Ferrules (Round, Square, Rectangular, Slit), SMA, FC, ST, etc.Fiberguide's high temperature assemblies use the supplier’s high temperature aluminium or gold coated fiber and a combination of specialized assembly techniques to provide a solution for optical sensing in sealed high temperature environments. Many of our customers’ products, systems or manufacturing processes require using a fiber optic cable assembly to allow the opto-electronic sensing components to be positioned remotely while maintaining a seal to keep contamination in or out. The data collected is often critical to the safety, operation, or efficiency of the end application. Please contact AMS Technologies – our staff of engineers and technical sales professionals unites with Fiberguide’s experienced design and production team in developing a solution specific to your project’s individual high temperature requirements! As an option, some fiber types can be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Configurations: Single Fiber, Multifiber Fiber Type: Any of Fiberguide’s High Temperature Metalized Fiber Hot End Connectors: Custom Machined Ferrules (Round, Square, Rectangular, Slit) Cold End Connectors: Custom Machined Ferrules, SMA, FC, ST, etc. Sealing: Sapphire Windows Available for Sealing and Protection Sheathing Options: Stainless Steel Monocoil, Ruggedized Stainless Steel Braided Hose Temperature Range: -269 to +700 °C

Product number:

SW10698

Manufacturer:

Fiberguide Industries

Shaped Fiber Tip Assemblies

Fiber Type All Silica, Step Index MM, Hard Clad; Single Fiber; Wavelength 190 to 1250 nm; Sheathing Acrylate, Polyimide, Nylon, Tefzel, Gold, Aluminium; Termination 905 SMA, FC/PC, ST/PC, Cleaved Ends, Polished Ends, Round 2.5mm Ferrule, FD-80 High Power, 905 High Power, CustomShaped fiber tip assemblies provide optimum control over beam delivery and/or increased efficiency of light collection. Fiberguide offers standard configurations like angles, ball, radiused, conical, chisel or diffuser tips, as well as custom designed shaped tip fibers assemblies for precise beam control. A shaped tip on the end of an optical fiber allows for a wide variety of different outputs and inputs; they are most commonly in the medical field as laser scalpels, to remove plaque buildup in arteries, to close varicose veins and to couple diodes into multi mode optical fibers. Shaped tips are also used to provide diffused outputs and as radial emitters, perpendicular to the face of the fiber. The shaped tips are bare or encapsulated in a glass tube, to prevent fluids and other materials from impacting the shape of the light output from the fiber. Fiberguide designs and manufactures shaped glass to manipulate the light inside fibers. Fiberguide offers shaped tips for a broad range of multi mode fibers, including step index MM fiber series like AFS/AFM/AFH/SFS/SFM/SFH all silica optical fibers, AFSH/SFSH hard polymer coat fibers, APC/SPC polymer clad fibers, APCH/SPCH hard clad fibers, AFR/SFR Uniclad™ high power fibers or Solarguide™ solarization resistant fibers, but also AGI/ASI anhydrous graded index fibers. For high temperature applications, some fiber types can be aluminium or gold coated on request. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Fiberguide’s experienced engineering team, industry leading fiber processing techniques, and proprietary design software can help enable any custom solution. Get in touch with AMS Technologies’ fiber optic team and discuss the requirements of your solution! Key Features: Assembly Type: Single Fiber Assemblies Fiber Types: All Silica, Step Index Multi Mode, Hard Clad Buffer Types: Acrylate, Polyimide, Nylon, Tefzel, Gold, Aluminium Core Sizes: 50 to 1000 μm Numerical Aperture (NA): 0.12 to 0.37 Wavelengths: 190 to 1250 (High OH), 300 to 2400 nm (Low OH ) Second End Connector Types: 905 SMA, FC/PC, ST/PC, Cleaved Ends, Polished Ends, Round 2.5mm Ferrule, FD-80 High Power, 905 High Power, Custom Certifications: ISO 9001:2015, ISO 13485:2016 Applications: Medical Lasers; Surgical Illumination; Diode Coupling; Optical Sensing; Laser Delivery for Material Processing; Communications/Pigtailing

Product number:

SW10694

Manufacturer:

Fiberguide Industries

Single Fiber Assemblies

Fiber Type Multi Mode; Single Fiber; Length ≤100 m; Wavelength 190 to 2400 nm; Sheathing PVC Tubing, Stainless Steel Monocoil; Termination SMA905/906, Cleaved End, Polished End, Cut EndFiberguide offers standard single fiber assemblies for a wide range of applications including spectroscopy, industrial sensing, and low power laser light delivery. These are available with a variety of optical fibers, industry standard connectors, and packaged using several kinds of sheathing. Beyond standard solutions, Fiberguide also offers a wide range of custom single fiber assembly options, including single mode, graded index and other fiber types as well as custom core to cladding ratios (1:1.1, 1:1.2, 1:1.4, 1:2.5). Also available are Fiberguide’s universal cladding fiber (UniClad) with a 500 µm cladding diameter, in addition to different jacketing options (Tefzel, Acrylate, Polyimide, and others), or Fiberguide’s industry-leading high temperature jacketing solutions – Thermocoat, aluminium, Vulcan Alloy and gold jacketed fiber assemblies for extreme environment applications up to +700 °C with resistance to most acids, bases and other hazardous conditions. Fiberguide’s range of custom single fiber assemblies is available with 25 connector options, 10 sheathing options and an entirely separate line of fiber assemblies designed to handle the high powers commonly found in industrial applications. As an option, some fiber types can be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. For the broad range of design features available please download the data sheet. And for your custom single fiber assembly, please contact AMS Technologies – our staff of engineers and technical sales professionals unites with Fiberguide’s experienced design and production team in developing a solution specific to your project’s individual requirements. Key Features: Fiber Type: Step Index Multi Mode Core Sizes: 50 to 1500 µm Wavelengths: 190 to 1250 (High OH), 300 to 2400 nm (Low OH ) Numerical Aperture (NA): 0.22 Connector Options: SMA905, SMA906 Sheathing Options: PVC Tubing, Stainless Steel Monocoil Standard Temperature Range: -40 to +100 °C Lengths: < 100 m Applications: Light Transfer; UV Lamps; Spectroscopy; Data Transmission; Laser Delivery; Remote Monitoring Applications

Product number:

SW10699

Manufacturer:

Fiberguide Industries

Solarguide™ Solarization Resistant MM Fibers

Multi Mode, Solarization (UV) Resistant; 190 to 1250 nm; Core Diameter 50 to 600 µm; Cladding Diameter 125 to 660 µm; Coating Polyimide, Aluminium; Numerical Aperture 0.22Fiberguide’s Solarguide™ series of silica core, silica clad, polymer or metal coated solarization resistant UV multi mode fiber is hydrogen infused to improve long-term attenuation stability at short ultraviolet (UV) wavelengths (190 to 230 nm). Solarguide™ fibers are the ideal choice for UV spectroscopy, lithography, excimer laser systems and UV curing applications that use Deuterium lamps or other UV sources below 230 nm. Solarguide™ fibers are available with either Polyimide/Thermocoat coating (UVS-THY) or aluminium coating (UVS-H2A) for high temperature applications. As a further option, Solarguide™ fibers can be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection. Solarguide™ fibers can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Step Index Multi Mode Fibers Pure Fused Silica Core / Fluorine Doped Silica Cladding Coatings: Polyimide, Aluminium Core / Cladding Sizes: 50/125 to 600/660 µm Standard Core/Clad Ratio: 1.1 Wavelengths: 190 to 1250 nm (High OH) Numerical Aperture (NA): 0.22 Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter 100% Proof Test Using 4-Axis Bend Method Thermocoat (Polyimide) certified to NAMSA Class VI Applications: Laser Surgery; Semiconductor Manufacturing; UV Illumination; Photo Initiated Chemistry; UV Curing; Analytical Instruments

Product number:

SW10705

Manufacturer:

Fiberguide Industries

UniClad™ High Power MM Fibers

Multi Mode, High Power; 190 to 2400 nm; Core Diameter 100 to 800 µm; Cladding Diameter 500 to 1000 µm; Coating Nylon; Numerical Aperture 0.20Fiberguide’s Universal Clad or UniClad™ series of Anhydroguide™ (AFR) and Superguide™ (SFR) high power silica core, silica clad, polymer coated multi mode optical fibers are designed for high power transmission and other applications where a large cladding relative to the core is beneficial. The UniClad fiber series features a fixed 500 μm cladding diameter with a 100 to 400 μm core size, making laser alignment and splicing easier. The larger 600 and 800 μm core sizes use proportionally larger cladding. While the AFR series features a low hydroxyl ion concentration (low OH) and works in the visible to IR range, SFR variants with high hydroxyl ion concentration are suitable for the UV to visible range. Both series are coated with NAMSA Class VI Nylon. As an option, fibers can be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection. Some fiber types can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range. Key Features: Step Index Multi Mode Fibers Pure Fused Silica Core / Fluorine Doped Silica Cladding Coating: Nylon Core / Cladding Sizes: 100/500 to 800/1000 µm Wavelengths: SFR (High OH) 190 to 1250 nm, AFR (Low OH) 300 to 2400 nm Numerical Aperture (NA): 0.20 Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter 100% Proof Test Using 4-Axis Bend Method Nylon certified to NAMSA Class VI Applications: High Power Applications; Spectroscopy ; Ultra-low Loss Assemblies; Low Focal Ratio Degradation Applications; Universal Dimensioning; Simplified Assembly

Product number:

SW10702

Manufacturer:

Fiberguide Industries

Fiberguide Industries, Inc. has been a leading US provider of fiberoptic solutions to the OEM markets since 1977. The comprehensive product line is based on ISO 9000:2000 and includes standard and custom high optical transmission multimode, singlemode and graded-index optical fibers from UV to NIR, optical fiber assemblies and discrete components. Fiberguide´s products are used in applications such as medical, sensing, laser delivery systems and smoke and particle detection.