Product information "Solarguide™ Solarization Resistant MM Fibers"

Multi Mode, Solarization (UV) Resistant; 190 to 1250 nm; Core Diameter 50 to 600 µm; Cladding Diameter 125 to 660 µm; Coating Polyimide, Aluminium; Numerical Aperture 0.22

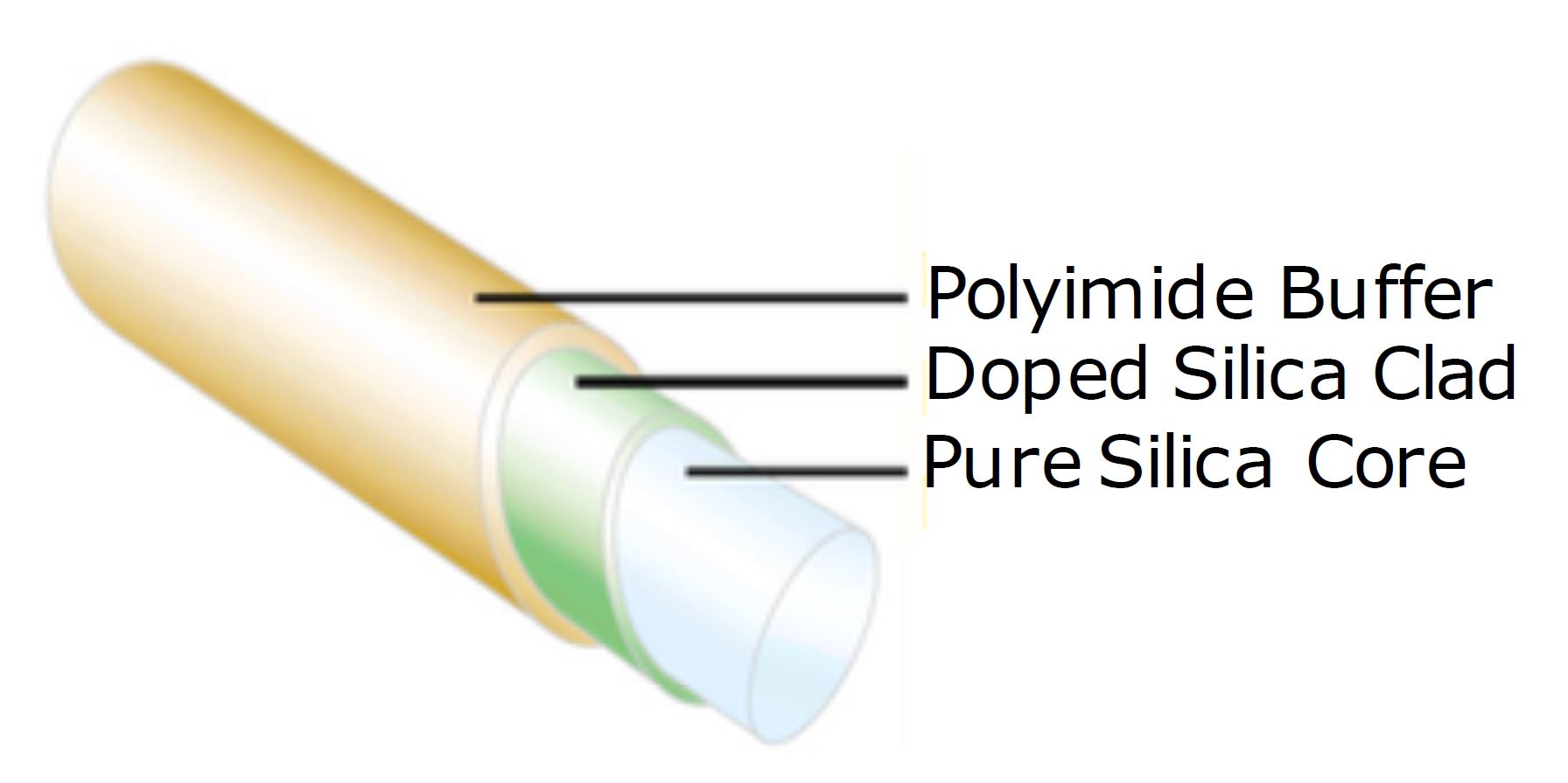

Fiberguide’s Solarguide™ series of silica core, silica clad, polymer or metal coated solarization resistant UV multi mode fiber is hydrogen infused to improve long-term attenuation stability at short ultraviolet (UV) wavelengths (190 to 230 nm).

Solarguide™ fibers are the ideal choice for UV spectroscopy, lithography, excimer laser systems and UV curing applications that use Deuterium lamps or other UV sources below 230 nm. Solarguide™ fibers are available with either Polyimide/Thermocoat coating (UVS-THY) or aluminium coating (UVS-H2A) for high temperature applications.

As a further option, Solarguide™ fibers can be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection.

Solarguide™ fibers can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications.

Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range.

Key Features:

- Step Index Multi Mode Fibers

- Pure Fused Silica Core / Fluorine Doped Silica Cladding

- Coatings: Polyimide, Aluminium

- Core / Cladding Sizes: 50/125 to 600/660 µm

- Standard Core/Clad Ratio: 1.1

- Wavelengths: 190 to 1250 nm (High OH)

- Numerical Aperture (NA): 0.22

- Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter

- 100% Proof Test Using 4-Axis Bend Method

- Thermocoat (Polyimide) certified to NAMSA Class VI

Applications: Laser Surgery; Semiconductor Manufacturing; UV Illumination; Photo Initiated Chemistry; UV Curing; Analytical Instruments