Product information "AFT/SFT Optical Fiber Tapers"

Fiber Type Single Mode, Multi Mode Step & Graded Index; Input Core Diameter 100 to 600 µm; Output Core Diameter 50 to 200 µm; Numerical Aperture 0.12, 0.26; Wavelength 180 to 2400 nm; Sheathing PVC, Stainless Steel

Fiberguide’s AFT/SFT series of optical tapers are used for mode mixing, lowering optical power density in high power applications, and converting numerical aperture (NA) in optical power delivery applications. Optical tapers can either be tower drawn, where the length is several meters, or they can be produced using bench-top equipment, making the length a few inches. In both cases, these optical tapers are continuous pieces of fiber, they are not spliced.

Tapered optical fibers can be made either by fusing a short tapered section onto a longer fixed diameter fiber or by very carefully controlling the drawing process to produce a single continuous fiber with an integral tapered section. For its AFT/SFT series, Fiberguide uses the latter process since it results in superior fiber strength, alignment precision and optical power transmission.

Tapered optical fibers cause optical mode mixing that tends to homogenize spatial power distribution. A larger input core diameter can prevent input damage and allow a smaller diameter pigtail for convenience in adapting to a wide range of optical applications.

Tapered optical fibers can be used as a passive optical component to alter the input and / or output divergence (N.A.) with regard to an optical fiber, as a high power coupler for laser energy, as this will spread the energy over a larger area, or simply as a device to relax tolerances in an optical system.

To ensure maximum efficiency of light transmission, the numerical aperture (N.A.) of the light entering the taper input should be 0.22 divided by the taper ratio. As an example, assume the input core diameter of the taper is 400 µm and the output core is 200 µm (2:1 taper ratio), then the N.A. of the light entering the taper will be 0.22/2 = 0.11.

Additionally, the fibers can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range.

Key Features:

- Fiber Type: Single Mode, Multimode

- Input Core Sizes: 100 to 600 µm

- Wavelengths: 190 to 1250 (High OH), 300 to 2400 nm (Low OH )

- Numerical Aperture (NA): 0.12, 0.22, 0.26

- Input-to-Output Ratios: Up to 3:1

- Connector Options: SMA905

- Sheathing Options: PVC Tubing, Stainless Steel Monocoil (Tower Drawn Tapers), Rigid Stainless Steel Tubing (Micro Tapers)

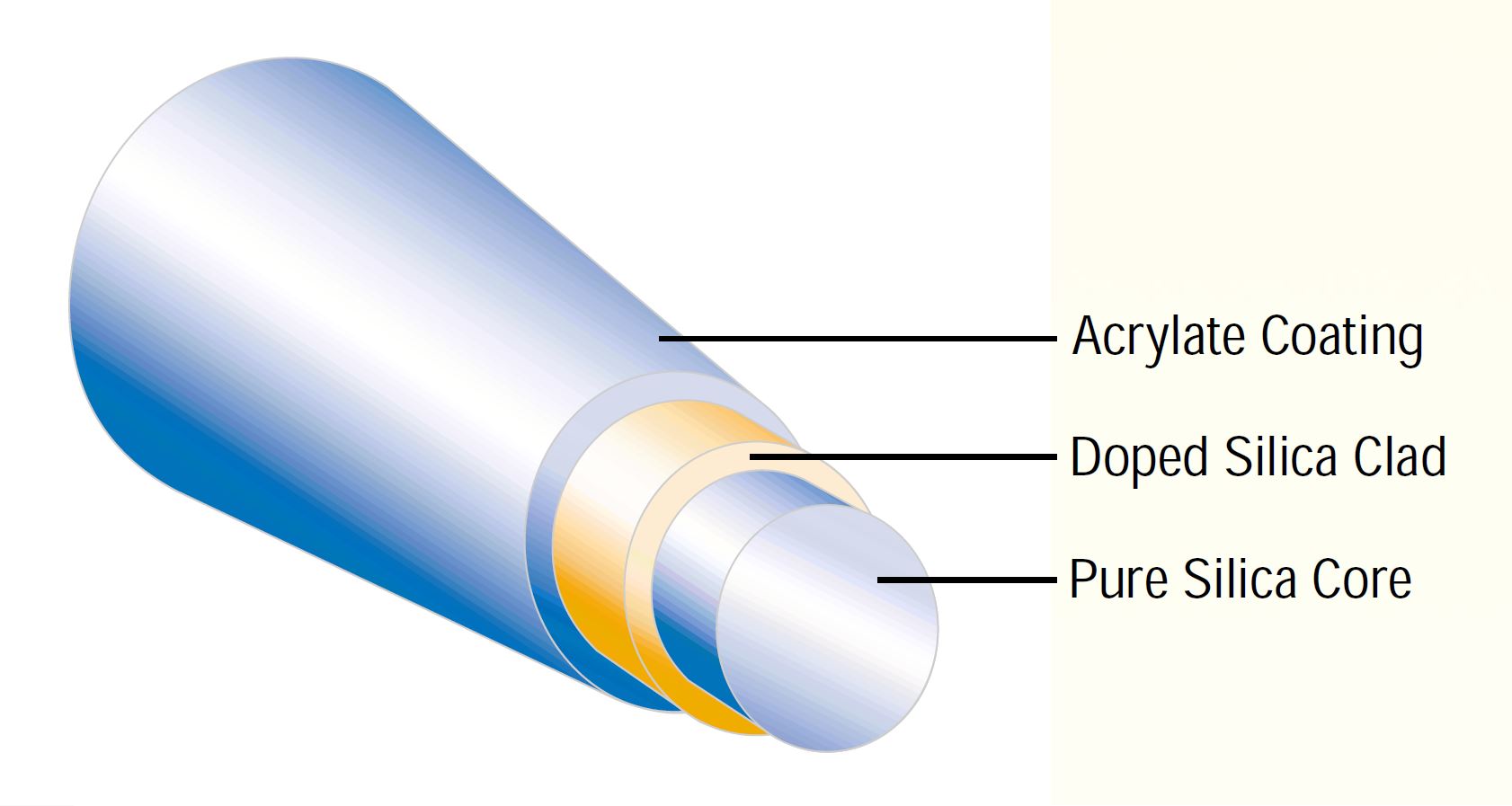

- Coating: Acrylate

- Length: Minimum Taper Length 2 m, Overall Length <50 m (Tower Drawn Tapers), ~ 6 inches Typical (Micro Tapers)

Applications: Laser Marking, Welding, Soldering; Fluid Level Sensors; Laser Surgery, Angioplasty, Lithotripsy; Non-linear Optics; Diode Laser Array Coupling; Spectroscopy; Analytical Instruments; Laser Delivery; Biosensors; Near-field Scanning Optical Microscopy\Raman and IR Spectroscopy; Humidity Sensing; Delivery Systems for Laser Diodes; High-power Laser Transmittance; Dynamic Position Sensing; Fluorescent Detection