Product information "AGI Graded Index MM Fibers"

Multi Mode, Graded Index; 850, 1300 nm; Core Diameter 50, 62.5 µm; Cladding Diameter 125 µm; Coating Acrylate, Polyimide, Aluminium, Gold; Numerical Aperture 0.20, 0.275

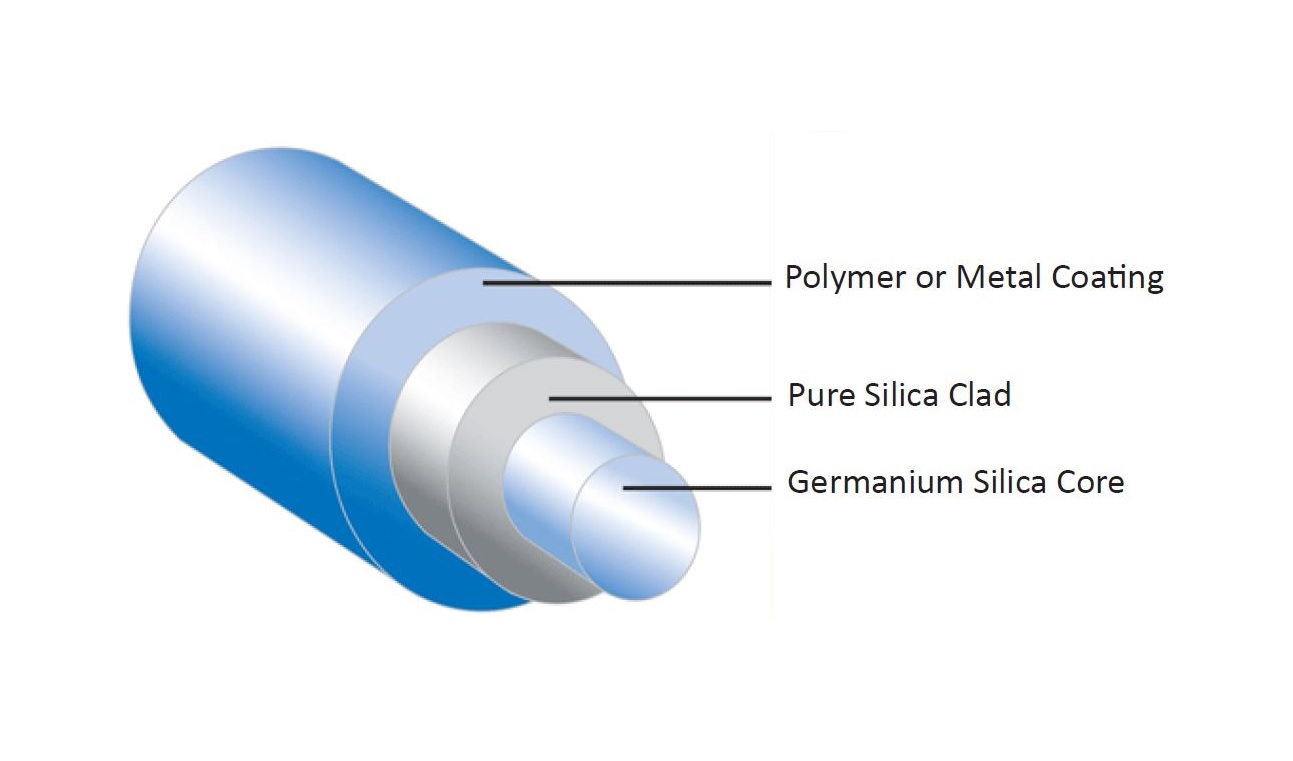

Fiberguide’s AGI series of anhydrous graded index multi mode silica core, silica clad, polymer or metal coated fibers feature a graded index profile instead of a step index profile. These fibers are primarily used in data transmission applications where more bandwidth is needed than step index fibers can offer. These fibers are available with acrylate coatings (-Y) and also high performance polyimide (-T), aluminum (-A) and gold (-G) coatings that allow them to exceed the temperature performance levels of standard fibers.

As a further option, AGI series fibers can be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection.

AGI series fibers can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications.

Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range.

Key Features:

- Graded Index Multi Mode Fibers

- Germanium Doped Fused Silica Core / Pure Fused Silica Cladding

- Coatings: Acrylate, Polyimide, Aluminium, Gold

- Core / Cladding Sizes: 50/125µm, 62.5/125µm

- Wavelengths: Optimized for 850nm & 1300nm

- Numerical Aperture (NA): 0.20, 0.275

- Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter

- 100% Proof Test Using 4-Axis Bend Method

Applications: Data Communications; Laser Systems; Medical Applications; Oil & Gas Down-Hole Sensing; Photonic Devices; Optical Sensor Systems