Product information "Fiber Arrays & V-Grooves"

Fiber Type Single Mode, Multi Mode, Polarization Maintaining (PM/PZ); Number of Fibers ≤128 (V-Grooves), ≤4096 (2D Arrays); Fiber Cladding Outer Ø 125 µm (V-Grooves), 125 to 220 µm (2D Arrays); Connector Options SMA, FC, ST, SC, LC, MTP, etc.

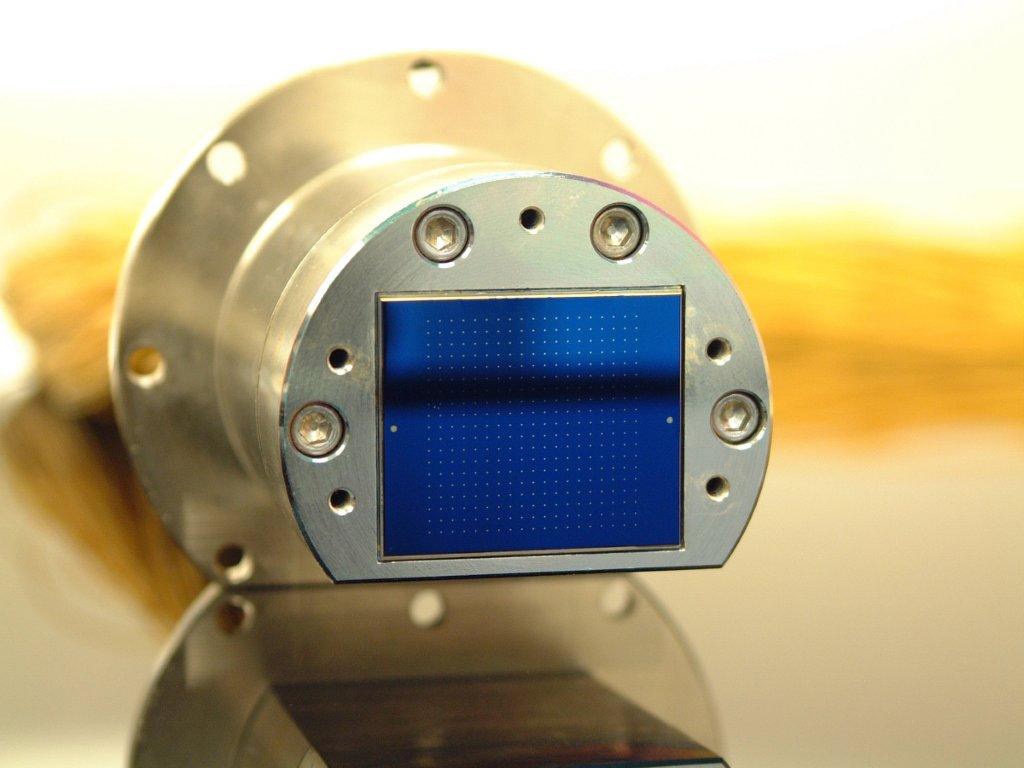

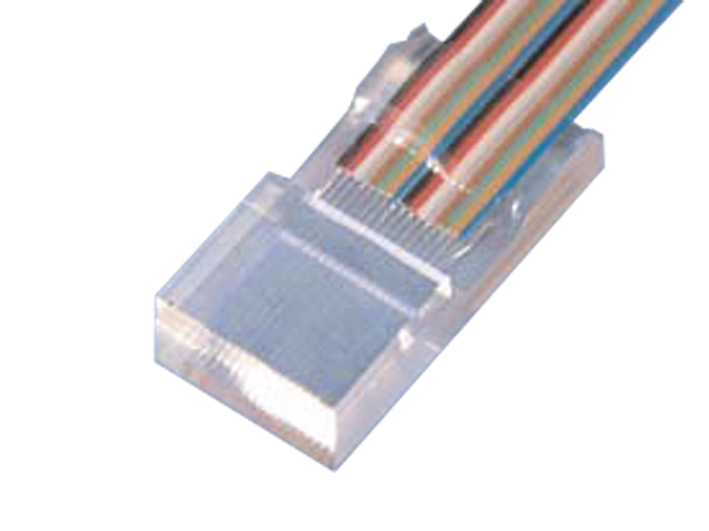

Fiberguide produces extremely tight tolerance one-dimensional (V-Grooves) and two-dimensional arrays using the supplier’s patented manufacturing techniques. These arrays range from a few fibers to thousands of fibers depending on the application.

Optical Arrays are used in optical switching and in sensing applications where spatial optical data is necessary, such as DNA sequencing, astronomy and nuclear research.

For high temperature applications, some fiber types can be aluminium or gold coated on request. Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range.

Key Features:

- Fiber Type: Single Mode, Multi Mode

- Array End: Precision Machined Housings, Silica V-Grooves or Custom Silicon Wafers

- Connector Options: SMA, FC, ST, SC, LC, MTP, etc.

- Packaging: Design and Production of Custom Array Housings and Sheathing Arrangements Available to Protect the Fiber Depending on the Application

- Standard Temperature Range: -40 to + 100 °C

Applications: Fiber Optic Switch; Signal Processing; Astronomical Analysis; Military Mapping; DNA Micro-array Technology; Optical Tomography