Product information "VGA V-Groove Assemblies"

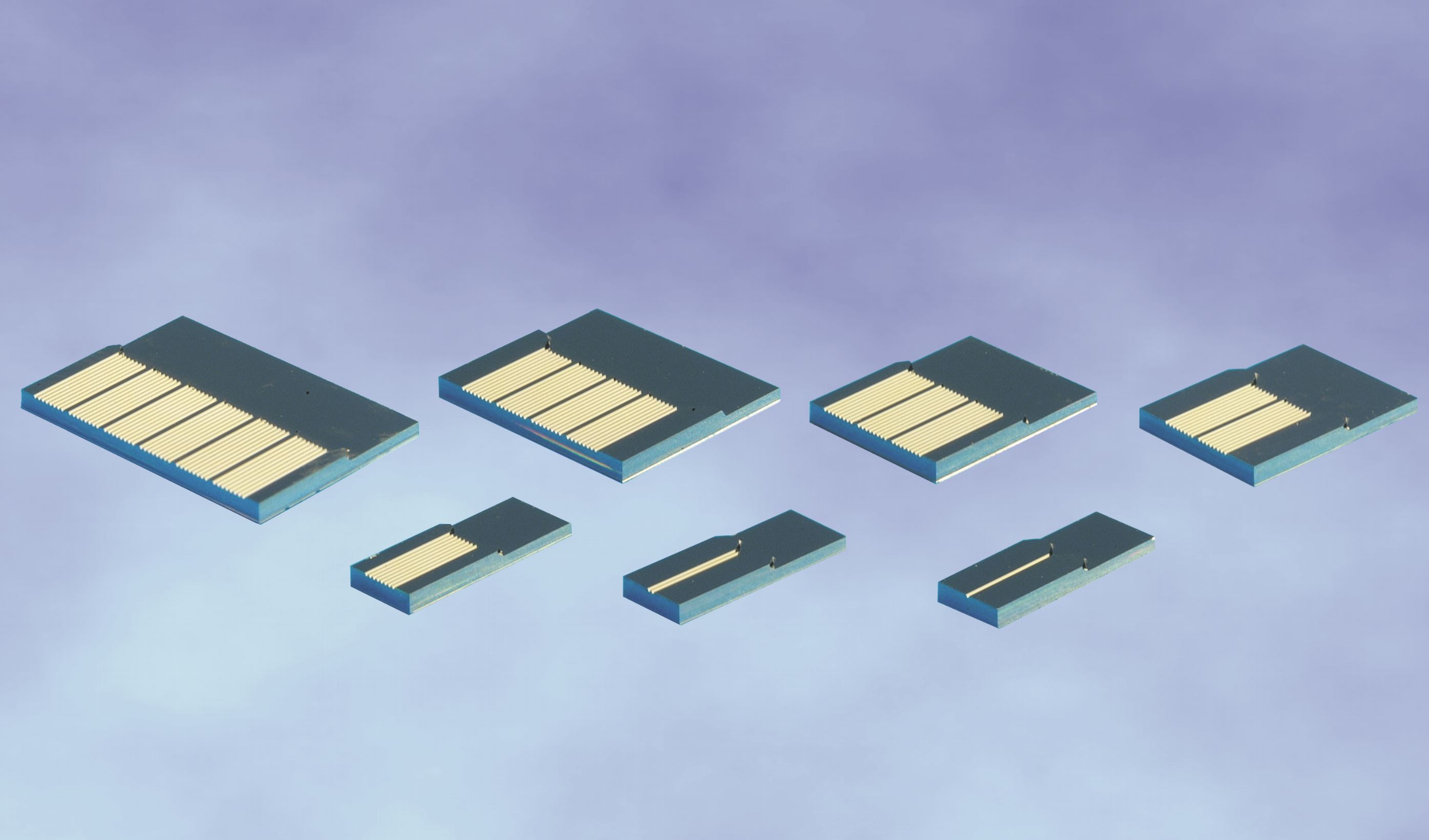

1 to 48 Channels; Channel Spacing 250 µm; Fiber Type SM, MM, PM; Connector Type SC, FC, ST, LC, MU; Insertion Loss <0.5 dB per Fiber

OZ Optics’ VGA series of V-Groove array assemblies assists in developing next generation photonic devices. The arrays are manufactured using precision silicon wafer V-Groove technology or Pyrex V-Groove in conjunction with a Pyrex lid, enabling sub-micron alignment accuracy with UV cure attachment capabilities.

VGA series V-Groove array assemblies are available with single mode (SM), multi mode (MM) or PANDAtype polarization maintaining (PM) fibers. Customization can even include different types of fibers assembled into a single array.

In general, OZ Optics uses polarization maintaining fibers based on the PANDA fiber structure when building polarization maintaining components and patch cords. However OZ Optics can construct devices using other PM fiber structures. OZ Optics also carries some alternative fiber types in stock, please contact AMS Technologies for availability. If necessary, OZ Optics is willing to use customer supplied fibers to build devices.

Standard PANDA style PM arrays are manufactured with the polarization axis (stress rods) aligned vertical to the V-Groove base within 3°. High grade assemblies with one to eight channels can be provided with the stress rods aligned to 1°. Arrays can also be provided with the fibers aligned parallel to the base, alternating axes or at custom angles. When supplied with a breakout and connectors, the alignment of the connector is also to the slow axis, within 3° for standard connectors or available to within 1.5° for high grade connectors.

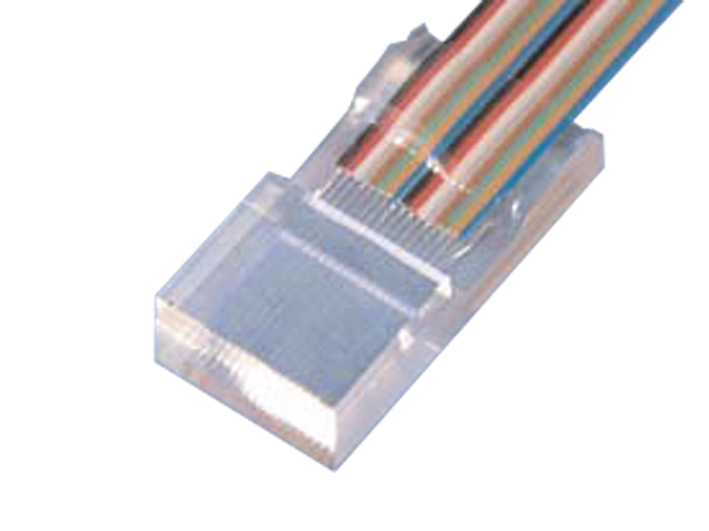

V-Groove array assemblies can be manufactured with a hermetic feedthrough attached. This enables the development of multichannel photonic devices capable of meeting Telcordia requirements. Fiber breakouts can also be added, to convert ribbonized fibers into separated fibers, capable of being connectorized.

Key Features:

- Up to 48 Fiber V-Groove Arrays

- Hermetic Feed-through Versions With Glass or Metal Solder Available

- Single Mode (SM), Multi Mode (MM) or Polarization Maintaining Fibers

- High Polarization Extinction Ratios up to 30 dB Available

- Ribbon or Individual Fibers

- Assemblies With Bare Fiber or 900 µm Jacketing

- With or Without Connectors

- 900 µm Jacketed Breakouts Available, up to 2 m Length

- Custom Configurations Possible for OEM Applications

- Designed to Meet Telcordia Specifications (GR 1221-core, GR 326-core)

Applications: Arrayed Waveguide (AWG) Devices; Planar Lightwave Chips (PLC); Dense Wavelength Division Multiplexers (DWDM); MEMS Devices; Miniaturized or Integrated Fiber Optic Components

| Active2: | TRUE |

|---|