Product information "mRC-KITs mini Recirculating Chiller Kits"

Compact Vapor Compression Chillers; Cooling Capacity 450-1000 W @+25°C; Single and Twin Versions; 1 to 5.5 l/min; Temperature Stability ≥±0.05K; Interface USB/Serial, Ethernet

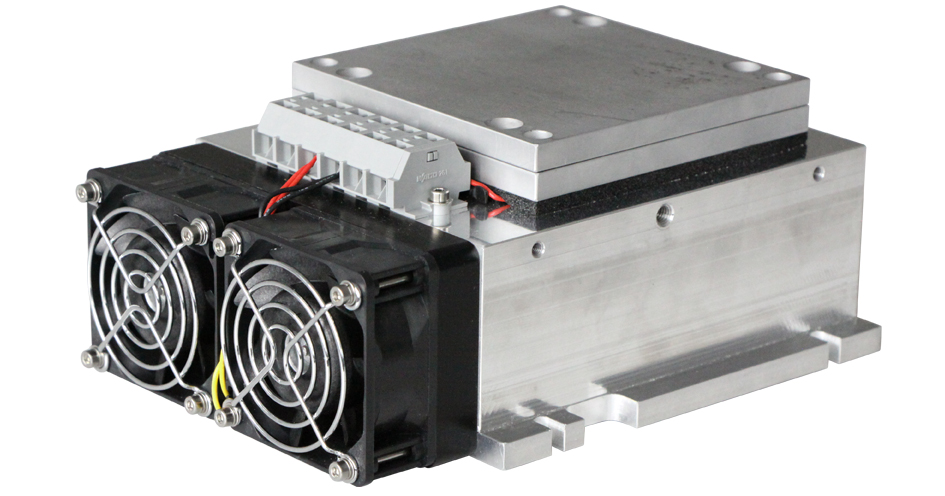

AMS Technologies’ mRC-KITs are “mini Recirculating Chiller” development kits for creating particularly compact compressor-based water cooling systems. All mRC-KIT versions feature vapor compression circuits and closed, pressurized recirculating water circuits. On the refrigeration side, miniature rotary compressors as well as customized condensers and evaporators are utilized to reduce the size.

The compressor’s BLDC motor is speed controlled by an inverter, eliminating annoying switching noise of hot gas bypass known from ON/OFF compressors. Throughout its speed range, the compressor twin pump design offers low vibration and low noise. Compact centrifugal pumps on the water circuit side also contribute to the compact size

Since the water circuit is pressurized, the mRC-KITs manage with very small tanks – without the risk of cavitation in the smoothly operating centrifugal pumps. Overpressure on the cooling system also prevents the ingress of bacteria and oxygen and thus extends the maintenance intervals.

While mRC-C-450-24-KIT and mRC-C-450-100/240 feature full chiller power and up to 450 W cooling capacity in a shoe box form factor, DmRC-C-900-100/240-KIT provides two independent water cooling systems in a 19-inch rackmount insert, which can provide a combined maximum cooling capacity of 900 W – either with each circuit cooling two heat loads independently of each other or with both circuits coupled in series, if only one circuit is needed. Our mRC-KITs are available either with a 24 VDC or with a 90 to 264 VAC wide-input-range power supply. The mRC-C-1000-100/240 can also be shipped as a 24V option to target OEM integration applications, that need a cooling capacity of around 1000W and where noise and vibrations are an issue.

Automatic fill and drain: Using automatic air and water pump technology integrated into the unit, the cooling water in the tank and pipe system of the mRC-KITs can be easily filled and drained at the push of a button – without the need for time-consuming tilting or removing the unit or the tank from the system and avoiding annoying spills or leaks.

mRC Recirculating Chillers

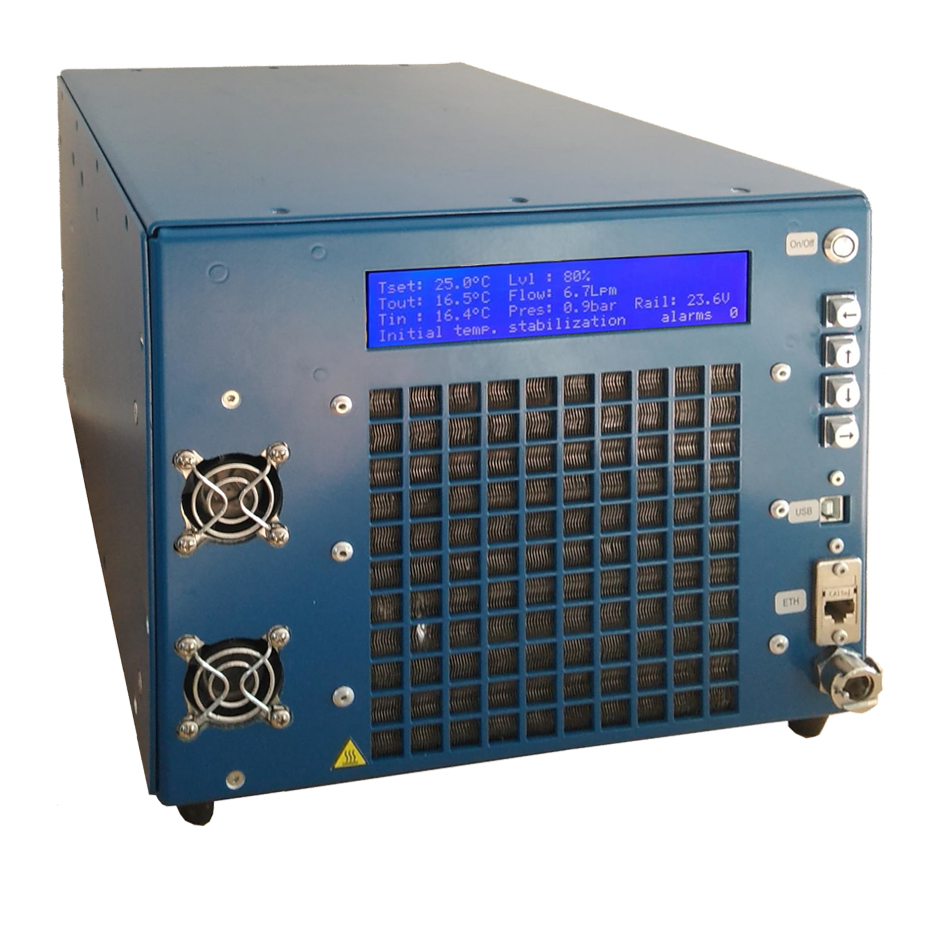

In addition to our mRC-KITs, AMS Technologies provides two recirculating chillers that are CE certified and available from stock. mRC-C-450-100/240 provides up to 500 W cooling capacity, while mRC-C-1000-100/240 features a more powerful compressor, capable of cooling capacities up to 1000 W. Both systems come with an integrated 90 to 264 VAC wide-input-range power supply.

IoT ready: An integrated Ethernet interface allows access to system parameters of the mRC recirculating chillers as well as remote control of the cooling systems via a web browser.

Your customized mRC-KIT: For customer requirements that cannot be covered by mRC-C-450-24-KIT, mRC-C-450-100/240 or DmRC-C-900-100/240-KIT, our thermal management specialists at AMS Technologies are happy to develop a completely tailor-made solution and offer all services from development and proof-of-concept all the way to series production. Contact us now to discuss your customized mRC-KIT!

Key Features:

- Recirculating Water Chilling Kits

- Ideal for Water Cooling Tasks up to 1000 W Cooling Capacity (Twater +25°C, Tambient +35°C)

- High Cooling Capacity in Compact Format, Easy to be Integrated in Customer Application

- 24 VDC and 100 to 240 VAC Derivatives Available

- Temperature Stability: Down to ±0.05 K

- Flow Rate: 0.5 bar @ 5.5 lpm (standard), 5 bar @ 5 lpm (optional)

- Smooth, Low-noise Operation with Low Vibration

- Automatic Fill & Drain

- PID Parameters and Fan Speed Adjustable

- Interfaces: USB/Serial, Ethernet (IoT Enabled)

Applications: Water Cooling of Lasers and Other Applications; Integration of Water Cooling Capabilities up to 1000 W in Systems with Limited Space