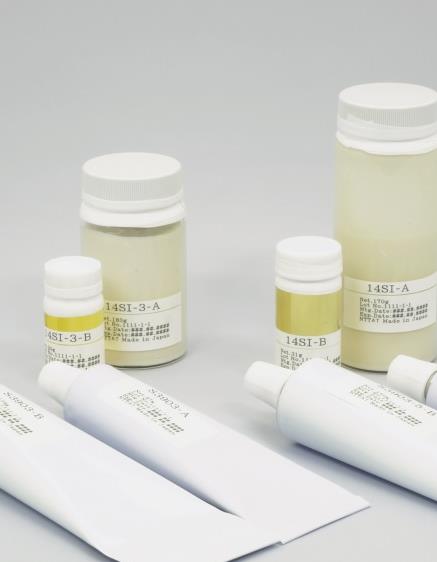

Product information "Sealants for Optical Parts"

Shear Bond Strength to SUS > 50-207 kgf/cm²; Moisture Permeability 0.7x10-8-3x10-7 cc*cm/cm²*s*cmHg; Hardness 20-46 Shore D; Curing Conditions Room Temperature, 24 h, +80, +100 °C, 1 h; Thermal Expansion Coefficient 100-200 ppm/°C; Tg -55-+49 °C

NTT-AT’s series of sealants for optical parts is suitable for applications like sealing the openings and junctions, etc. of protective casings. These sealants do not contain phthalate ester which has been listed in the RoHS directive (EU)2015/863.

In order to increase the long-term reliability of mechanical protection, moisture prevention, etc., optical parts are housed in a protective case made of metal or plastic. Through the special features of NTT-AT’s two-component sealants used for the openings and junctions of protective cases, the reliability, especially moisture prevention reliability, is greatly expanded.

The low moisture permeability type sealants (OS5958 and OS5962) feature a low moisture permeability coefficient and thus very reliably shut out moisture (humidity), while the high-flexibility type sealants (OS5980 and OS-48) feature very little internal stress that would cause transmission loss in optical fiber.

For long-term trust, a product must clear the tests conducted by the users themselves. If you have been unsatisfied with conventional products in the past, please test out NTT-AT’s sealants.

In case you need any consulting regarding issues related to sealing or adhesion, please contact the AMS Technologies optical adhesives experts to discuss the detailed challenges of your application.

Key Features:

- Two-component Sealants: Epoxy/Amine or Butylene/Butylene

- Low Moisture Permeability: 0.7 x 10-8 to 3 x 10-7 cc*cm/cm²*s*cmHg

- Low Moisture Permeation is Even at High Temperatures

- High Flexibility

- Low Stress on Inner Parts During Curing and Heat Cycle

- Long Pot Life: 2, 3 h

- Thermal Expansion Coefficient: 100 to 200 ppm/°C

- Hardness: 20 to 46 Shore D

- Shear Bond Strength to SUS: 44 to 207 kgf/cm²

- Curing Conditions: Room Temperature, 24 h or +80 °C/+100 °C, 1 h

- Colour (Pre-Curing): Transparent, White, Black

- Glass Transition Temperature Tg: -55 to +49 °C

Applications: Sealing of Protective Casing for Optical Parts; Sealing of Electronic Components and General Electric Parts; Moisture Prevention; Assembly of All Types of Devices