Product information "Adhesives for Fiber Array Assemblies"

Viscosity 70->20,000 mPas; Shear Bond Strength > 69->200 kgf/cm²; Bending Adhesion Strength 9-25 kgf/cm²; UV Curing Conditions 10-100 mW/cm², 5, 10 min; Colour Light Yellow, Colourless, White; Tg +42-+219 °C

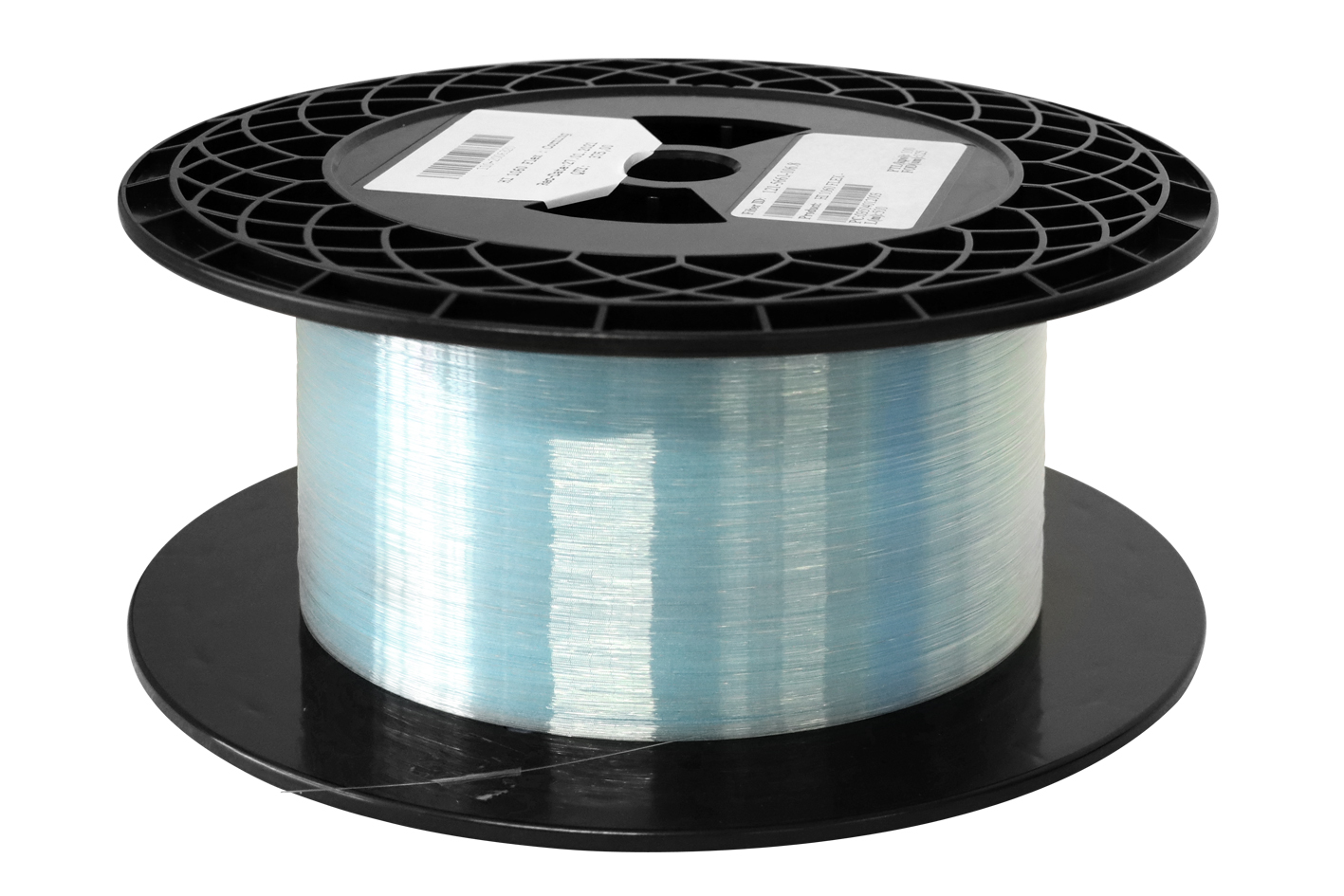

NTT-AT’s series of adhesives for fiber array assemblies feature high moisture resistance and excellent workability for v-groove fixing or optical fiber fixing.

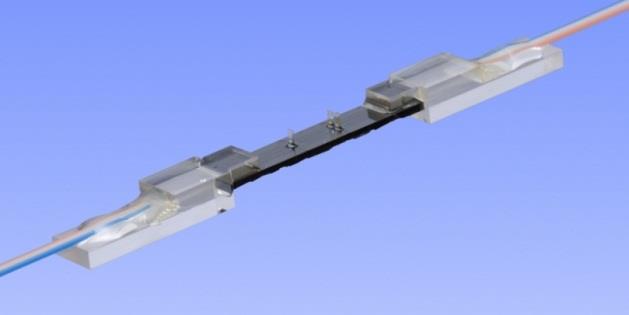

Fiber arrays are used for the input and output of optical waveguide devices. NTT-AT’s AT3925M, AT9390, AT9968, AT3727E and AT3728E epoxy-based optical adhesives are used for fixing the v-grooves and have realized price reductions while enhancing moisture resistance compared to conventional products. These adhesives can be polished after assembly.

NTT-AT’s AT9575M (epoxy) and AT8105 (acrylate) adhesives for optical fiber fixing have gained popularity for their good workability as non-fluid adhesives.

NTT-AT has executed durability tests that have shown no peeling of a fiber array after 2,000 hours at +85 °C and 85% of humidity. With viscosities that are appropriate for the usage location, the adhesives for fiber array assemblies are easy to use. While the adhesives for fixing v-grooves show fluidity, the optical fiber fixing adhesives’ consistency is that of a paste, suitable for protecting the fiber.

In case you need any consulting regarding issues related to adhesion, please contact the AMS Technologies optical adhesives experts to discuss the detailed challenges of your application.

Key Features:

- Excellent Durability

- Just the Right Viscosity for Easy Application: Non-liquid Viscosity for Fiber Fixation, Low Viscosity Fluid for Fiber Fixation into V-Type Groove

- Heat-proof: Maximum Glass Transition Temperature Tg of Over +200 °C (AT3925M)

- Viscosity: 70 to >20,000 mPas

- Shear Bond Strength: > 69 to >200 kgf/cm²

- Bending Adhesion Strength: 9 to 25 kgf/cm²

- UV Curing Conditions: 10 to 100 mW/cm², 5, 10 min

- Colour (Pre-Curing): Light Yellow, Colourless, White

- Glass Transition Temperature Tg: +42 to +219 °C

Applications: Gluing of Fiber Array Assemblies; V-Groove Fixing; Optical Fiber Fixing