Product information "Adhesives for Optical Waveguides"

Refractive Index 1.458-1.567; Viscosity 145-2,000 mPas; Optical Transmittance (@1 mm, 1.3 µm) 82%-94%; Bond Strength 99->247 kgf/cm²; UV Curing Conditions 10, 30 mW/cm², 5, 10 min

You are looking for PLC and fiber array adhesion with high reliability? Try NTT-AT’s series of adhesives for optical waveguides!

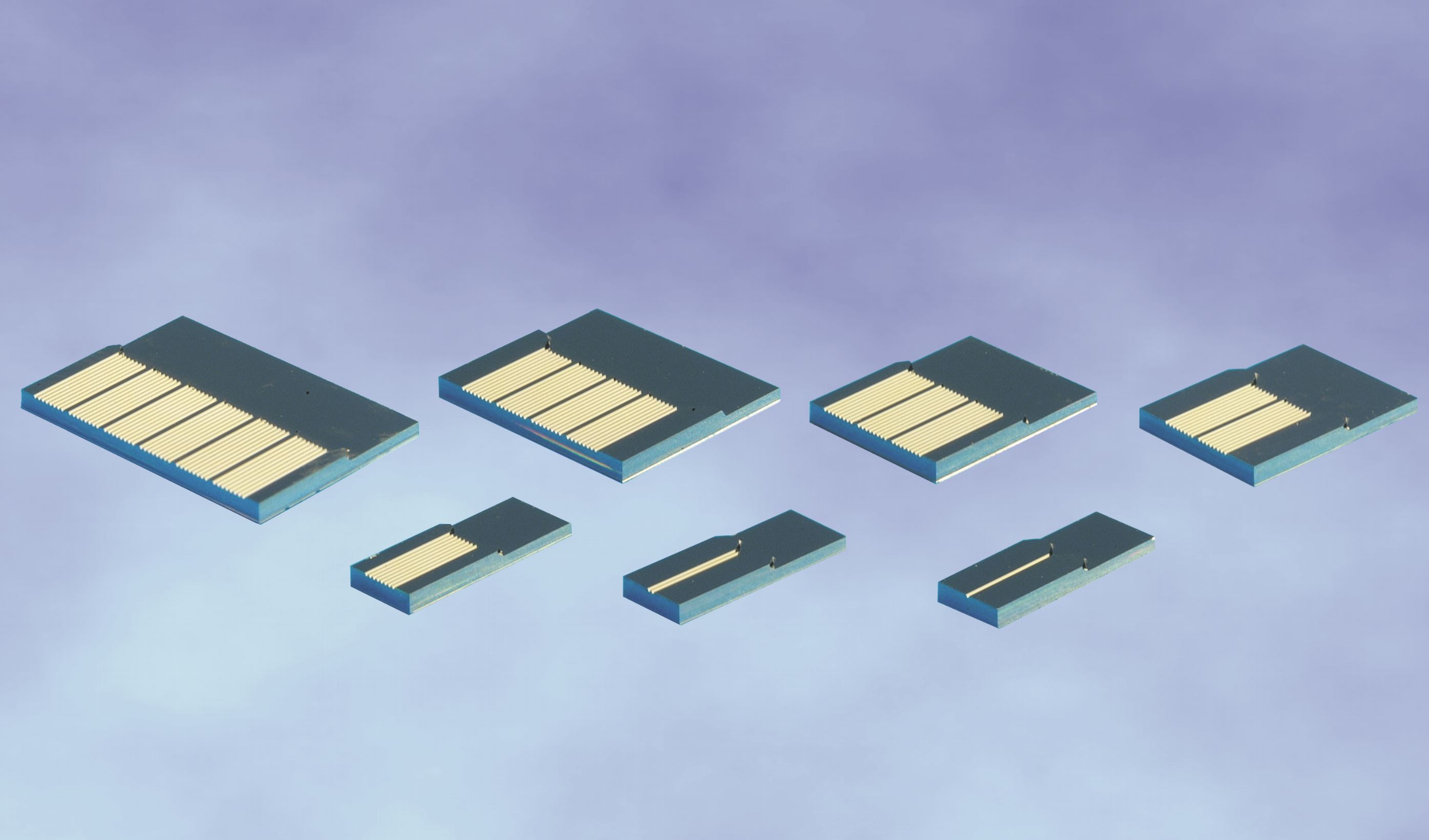

Within this series you find acrylate-based adhesives (AT6001, AT8224)with excellent durability that have cleared a large number of reliability tests. Epoxy adhesives are also part of this series, with a refractive index that can be accurately controlled within a range of 1.456 to 1.567 (±0.005, Na-D) – or with a fixed refractive index that is the same as quartz to deliver low reflectance (GA700L, GA700H).

UV curing of the adhesives for optical waveguides allows for adhesion in a short time frame and makes alignment easy. The adhesives withstand a solder reflow process for Si Photonics (+260 °C).

In order to achieve high reliability, a product must clear the tests conducted by the users themselves. If you have had even just a bit of dissatisfaction in reliability test results in the past, please put NTT-AT’s adhesives for optical waveguides to the test.

In case you need any consulting regarding issues related to adhesion, please contact the AMS Technologies optical adhesives experts to discuss the detailed challenges of your application.

Key Features:

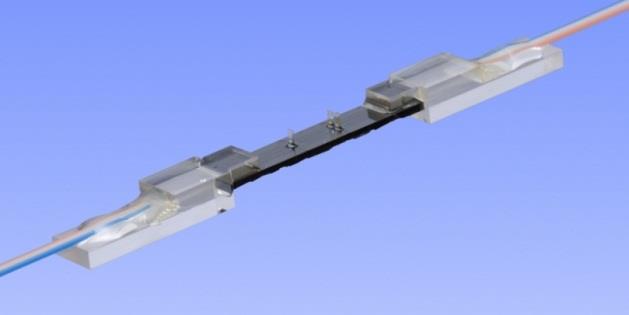

- Optical Adhesive Used for PLC to Fiber Link-up

- Precision Refraction Index of 1.458 to 1.567 (±0.005, Na-D) Provides Controllability

- Ultraviolet (UV) Curing Conditions: 10, 30 mW/cm², 5, 10 min

- Very Little Adhesion Loss Due to Heat or Moisture, Providing High Durability

- Viscosity: 145 to 2,000 mPas

- Optical Transmittance: 82% to 94% (@1 mm Thickness, Wavelength 1.3 µm)

- Bond Strength: 99 to >247 kgf/cm²

Applications: Gluing of Optical Waveguides; PLC to Fiber Link-up; Silicon Waveguide to Fiber Link-up