Product information "CP10/CP12/CP15 Tubed Cold Plates"

Press-Lock Technology; Thermal Performance 0.004 to 0.059 °C/W; Max. Pressure 10 bar; Max. Flow Rate 4, 8 l/min; Straight Fittings

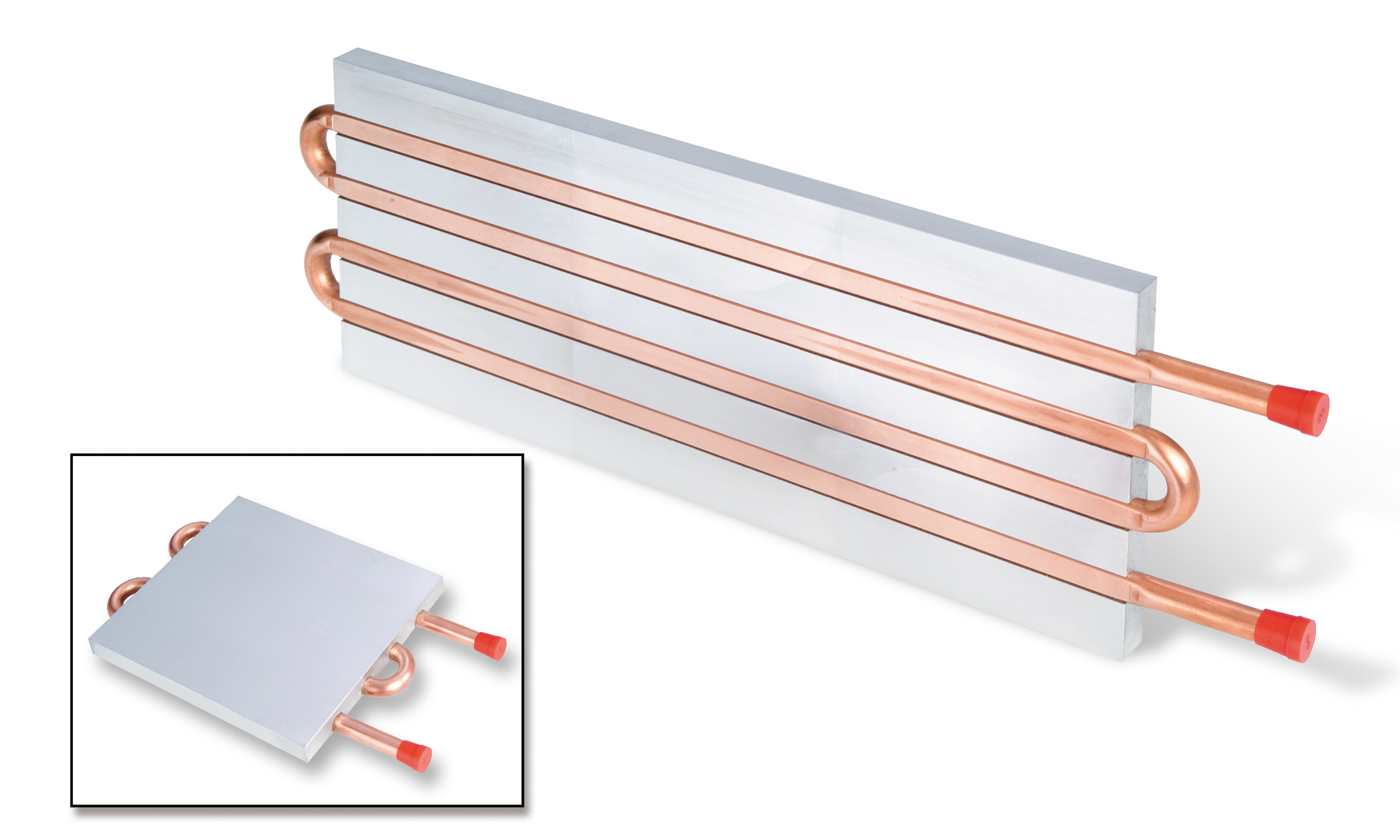

Lytron’s CP10/CP12/CP15 series of standard tubed cold plates provide cost-effective thermal solutions for component cooling applications where the heat load is low-to-moderate. These tubed cold plates consist of copper or stainless steel tubes pressed into a channeled aluminum extrusion.

The CP10/CP12/CP15 series of tubed cold plates is manufactured using Lytron’s proprietary Press-Lock technology, which mechanically locks the tubes into the aluminum plate. Press-Lock technology eliminates the need for performance-limiting epoxy between the tube and the plate, resulting in superior thermal performance. Compared to similar tubed cold plates, the CP12 cold plate offers 30% better performance and the CP15 offers 40% to 50% better performance.

Copper tubes are compatible with water and most other common coolants, while stainless steel tubes (CP10 only) can be used with deionized water or corrosive fluids. Each tubed cold plate has a single tube with no joint, ensuring leak-free operation.

The tubes of the CP12 and CP15 cold plates are coplanar with the plate to allow for dual-sided mounting. The cold plate's tube side offers higher performance as the copper tubes are in direct contact with the component being cooled.

CP10 models are available with 9.5 mm copper and stainless steel tubes in 2-pass or 4-pass configuration for single-sided mounting. CP12 models are available with 9.5 mm copper tubes in 4-pass configuration for dual-sided mounting. CP15 models are available with 6.4 mm copper tubes in 6-pass configuration for dual-sided mounting.

If you can’t find a tubed cold plate that meets your requirements, please get in touch with the AMS Technologies thermal technology experts to discuss your customized solution!

Key Features:

- Thermal Performance: 0.004 to 0.059 °C/W @ 7.6 l/min (3.8 l/min for CP15)

- Fluid Compatibility: Water, Common Coolants (Copper Tubes); Deionized Water, Corrosive Fluids (Stainless Steel Tubes)

- Configuration: 2-pass (CP 10), 4-pass (CP10, CP12), 6-pass (CP15)

- Mounting Surface: Single Sided (CP 10), Double Sided (CP12, CP15)

- Tube Diameter: 9.5 mm (CP10, CP12), 6.4 mm (CP15)

- Fitting: Straight

- Plate Material: Aluminium

- Maximum Pressure: 10 bar

- Maximum Flow Rate: 8 l/min, 4 l/min (CP 15)

Applications: Component Cooling Where the Heat Load is Low-to-moderate