Product information "AFS-G/SFS-G/AGI-G/ASI-G Gold Coated High Temperature Fibers"

Gold Coated, Single Mode, Multi Mode; 190 to 2400 nm; Core Diameter 50 to 400 µm; Mode Field Diameter 4.3, 9.0 µm; Cladding Diameter 125 to 440 µm; Numerical Aperture 0.12 to 0.275

Fiberguide’s AFS-G/SFS-G/AGI-G/ASI-G series of gold coated high temperature optical fibers is designed to achieve the widest temperature range (-269 to +700 °C) of any optical fiber on the market. This, combined with excellent corrosion resistance, and the fiber’s ability to be soldered or brazed, makes it the ideal fiber for many high temperature applications such as turbine flame monitoring, oil and gas down-hole sensing, and high vacuum or pressure applications.

As an option, some types of gold coated high temperature fibers can be provided with a broad selection of shaped tips – standard configurations as well as custom designed shapes. Shaped tip fibers provide optimum control over beam delivery and/or increased efficiency of light collection.

Some of the fibers can also be end capped to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface, commonly the point of laser damage. End cap diameters and lengths are offered for select numerical apertures and fiber cores size, but can be easily customized for a variety of fiber types and specialized applications.

Additionally, all fiber types can be equipped on demand with Fiberguide’s patented RARe Motheye anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range.

Key Features:

- Multi Mode (Step/Graded Index) or Single Mode Fibers

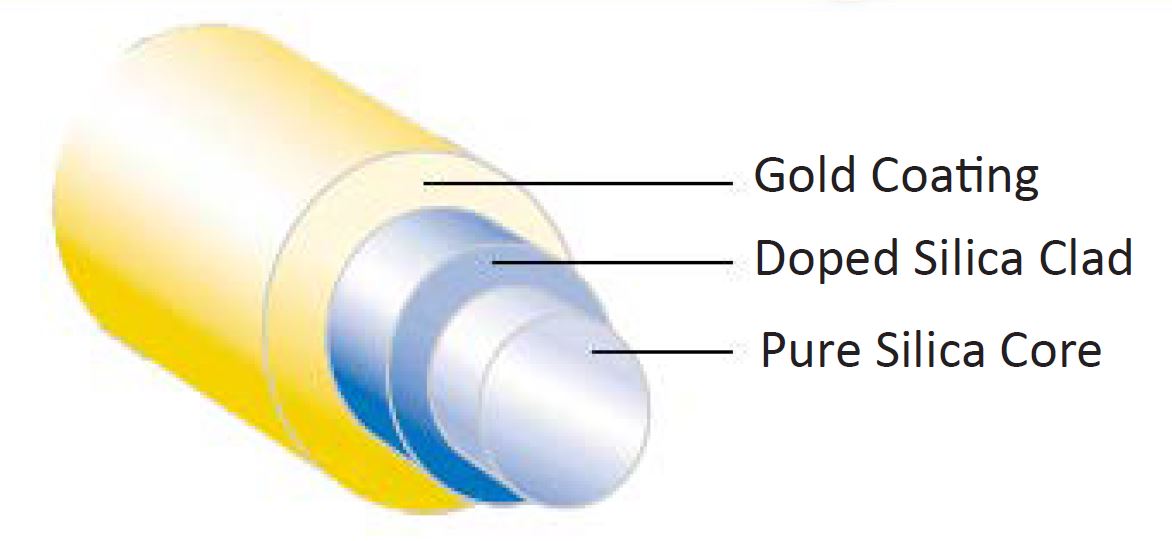

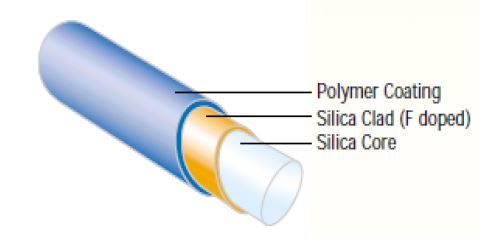

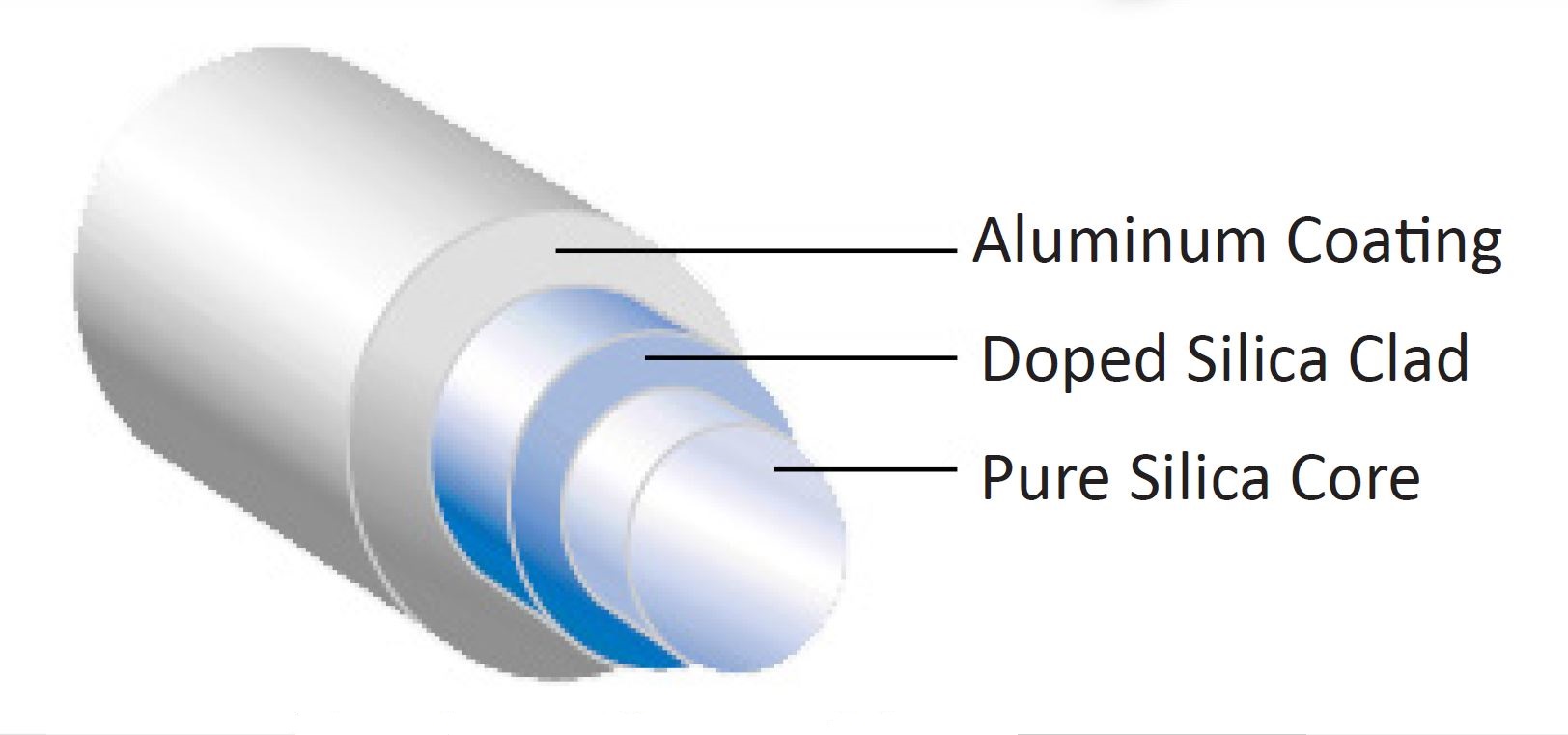

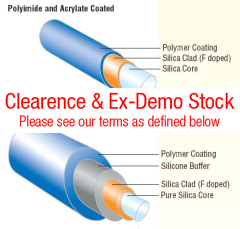

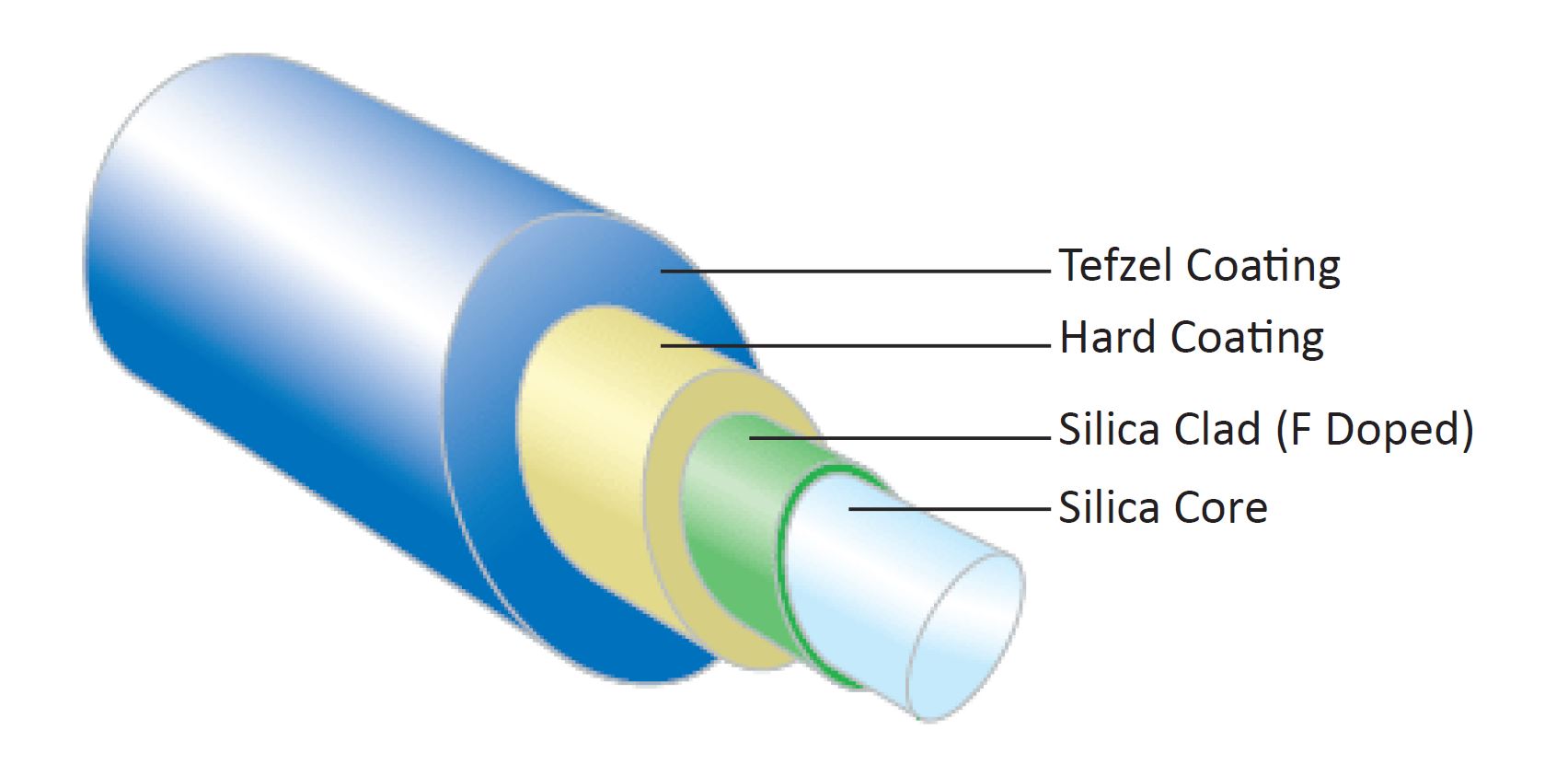

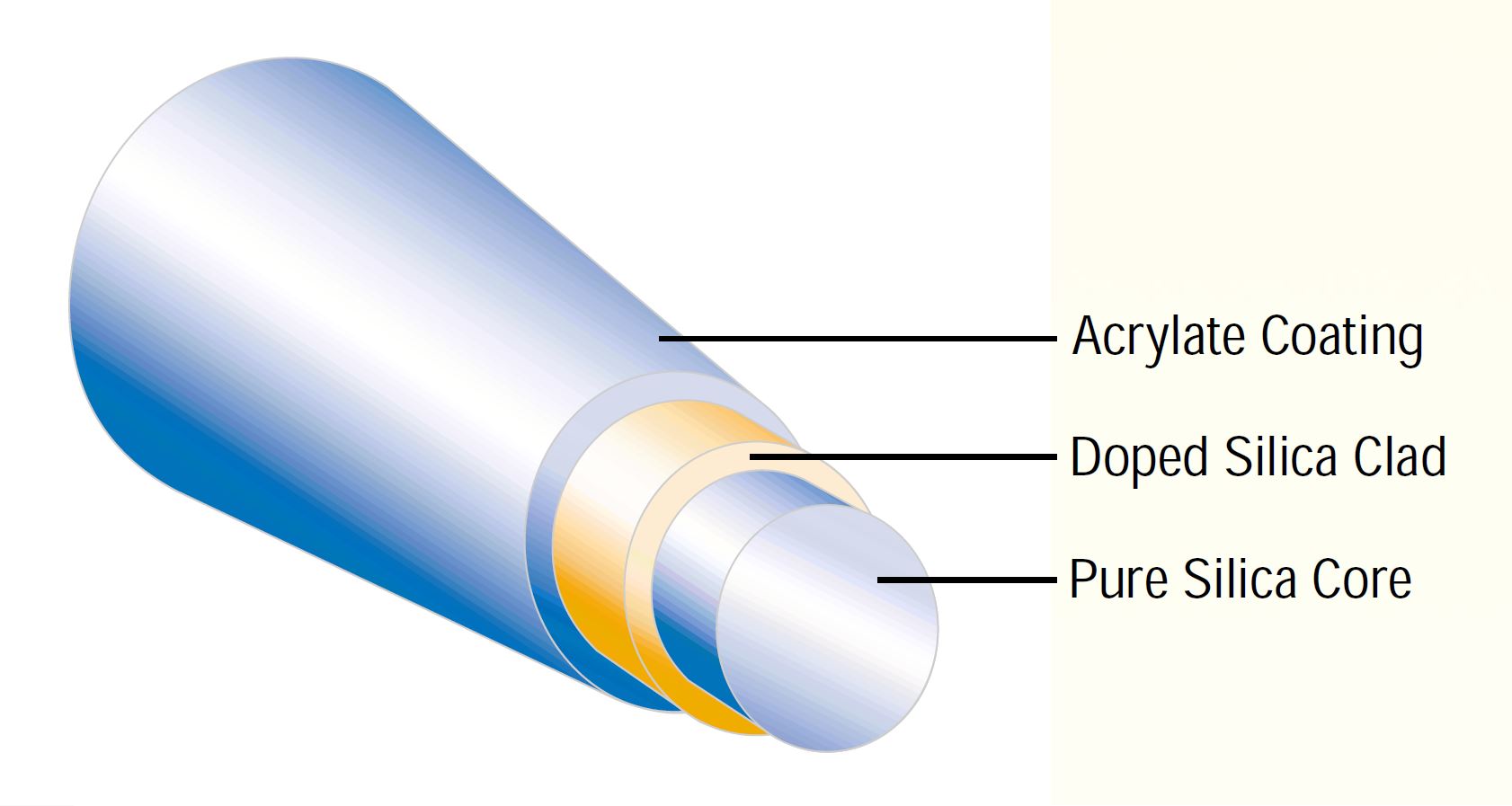

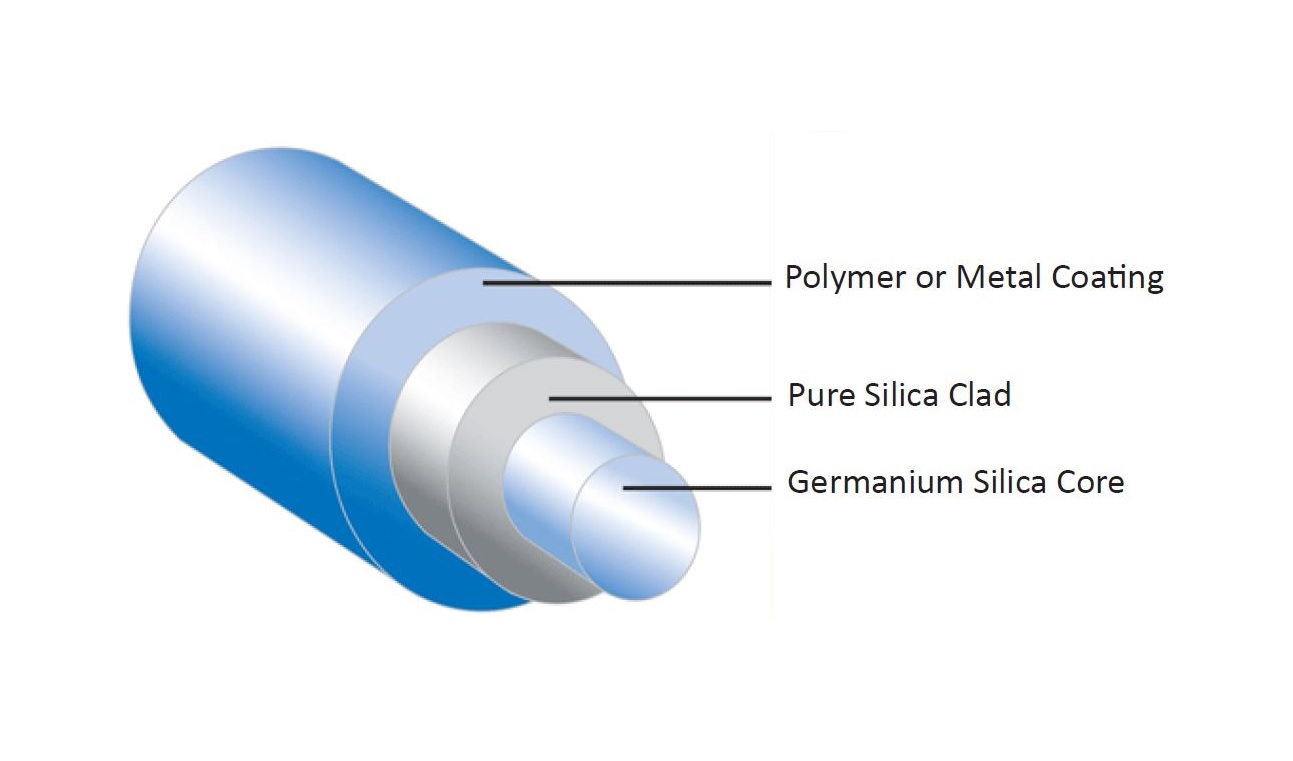

- Pure/Germanium Doped Fused Silica Core, Fluorine Doped/Pure Silica Cladding

- Coating: Gold

- Core / Cladding Sizes: 50/125 to 400/440 µm (MM)

- Mode Field Diameter / Cladding Sizes: 4.3/125, 9.0/125 µm (SM)

- Numerical Aperture (NA): 0.12 to 0.275

- Recommended Bend Radius: Short Term 100 x Clad Diameter, Long Term 200 x Clad Diameter

- 100% Proof Test Using 4-Axis Bend Method

Applications: Turbine Flame Monitoring; Oil and Gas Down-hole Sensing; High Vacuum Applications; High Pressure Applications