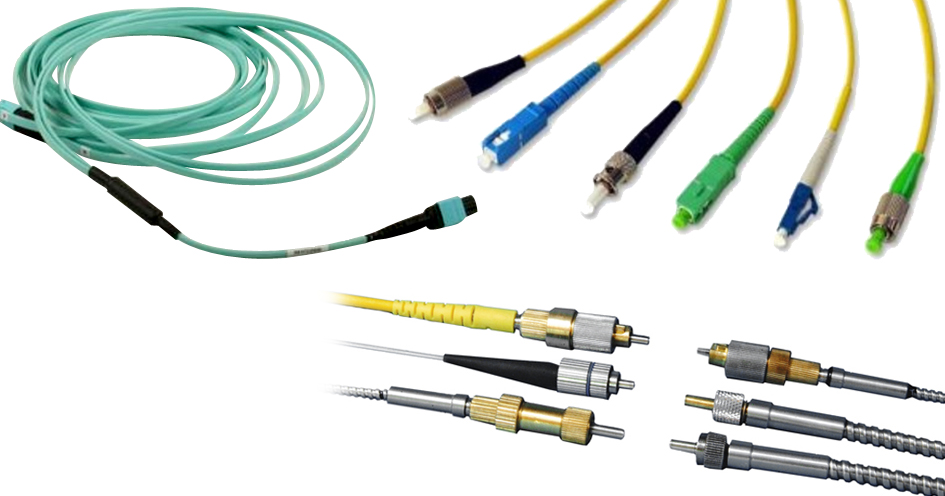

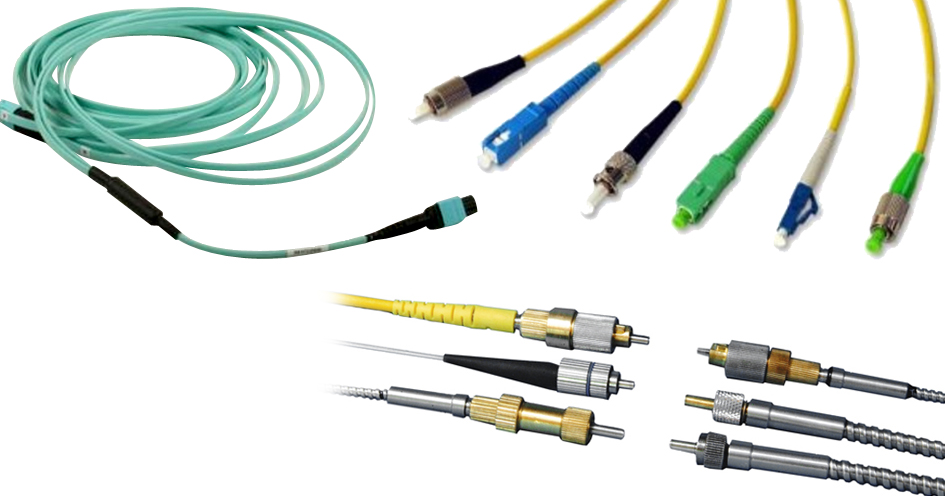

Patch Cables, Bundles, Assemblies

Product Portfolio

AMS Technologies carries a broad portfolio of fiber optic patch cables, including single mode (SM), multi mode (MM) and polarization maintaining (PM) patch cables with a large list of different connectors like FC, SC, ST, LC, MU, SMA905, MTP or MPO, connector finishes, coatings and fibers available for customization. High-power or hermetically sealed patch cables are also available.

Our offerings of fiber optic bundles and assemblies range from multi-fiber bundles, consisting of multiple fiber inputs and outputs with different cross-sections and geometries, to high temperature assemblies, all the way to one-dimensional (V-Grooves) and two-dimensional fiber arrays.

Our patch cables, fiber bundles and assemblies can be manufactured to your requirements and specifications – get in touch with the AMS Technologies fiber experts today to discuss your customized patch cable, fiber bundle or assembly solution.

Related Products

Our large portfolio of optical fibers – including specialty fibers – spans from just a few meters of highly engineered fiber to several kilometers of SMF-28 compatible material. For a wide wavelength range we offer single mode (SM) fibers, multi mode (MM) fibers and polarization maintaining (PM) fibers as well as doped fibers or plastic optical fibers (POF).

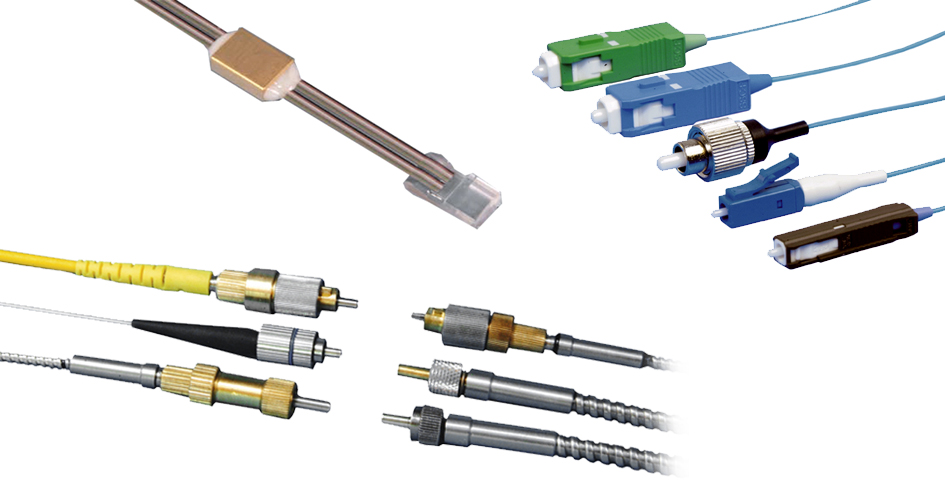

Complementing our optical fiber offerings, we carry a large portfolio of fiber components like fiber connector kits and fiber connector parts, accompanied by a range of corresponding female mating sleeves and adapters, fiber feedthroughs, fiber optomechanics, fiber or receptacle collimators and focusers, fiber optic WDMS, combiners, splitters, couplers, delay lines, isolators, amplifiers or circulators, but also fiber optic switches, polarization controllers, attenuators and other fiber components.

AMS Technologies can also offer an end-to-end solution for the assembly and test of fiber connectors that is exactly tailored to your requirements. In our broad portfolio you can find tools for stripping and cleaving your fibers, gluing and curing the fiber into the fiber connector using optical adhesives, polishing and cleaning of fiber optic end faces (especially important if the fiber is used with higher optical power), and finally testing your fiber connector with microscopes, interferometers as well as handheld and automated test equipment measuring return loss.

Definition

Fiber optic or glass fiber patch cables are used to connect passive fiber components or active optical devices. A patch cable is a single glass fiber of various length with fiber connectors at both ends. To be used in different environments, the fiber can have a protective buffer with or without strain relief elements.

All types of fibers can be used to build single mode (SM), multi mode (MM) and polarization maintaining (PM) patch cables. They can be assembled as well with many different fiber connectors. If only one fiber end is connectorized, the assemblies are called pigtails or patch cable with one bare end. To specify a patch cable, it is necessary to specify the fiber type, the buffer, the mounted connectors (eventually different connector polish) and the fiber length.

A fiber assembly is defined as “a length of fiber optic cable that has been terminated with a connector, pigtail or other component”. Fiber bundles combine multiple fibers, that can each be a different kind of fiber, terminated with a different connector, in one common assembly with a heavy-duty outer jacket.

Fiber bundles and assemblies are designed and manufactured using a broad variety of optical fiber types, ranging from pure silica (core and clad) or silica core / plastic clad fibers to borosilicate glass fibers, plastic optical fibers, fluoride fibers, chalcogenide fibers, doped fibers or polarization maintaining fibers.

Alternative Terms: Fiber Optic Patch Cable; Fiber Optic Patchcord; Fiber Optic Bundle; Fiber Optic Assembly