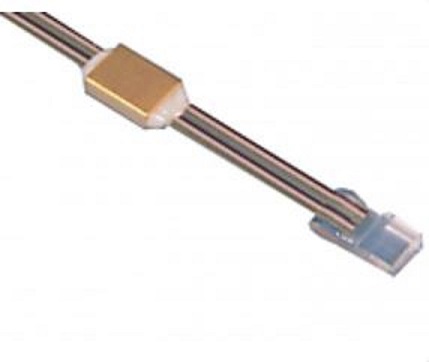

Product information "HPMJ Hermetically Sealable PM Patch Cables"

Polarization Maintaining Patchcords. Metal Solder; Polarization Extinction Ratio >20, >25, >30 dB; Helium Leak Rate<10-8 ATM-cc/s; Operating Temperature -40 to +85 °C; Max. Installation Temperature +210 °C

OZ Optics’ HPMJ series of hermetically sealable polarization maintaining (PM) patchcords with metal solder are designed for today's stringent requirements for component packaging. Utilizing metalized fiber and a proprietary sealing process, these patchcords feature a rugged hermetic feedthrough that can be soldered into an opto-electronic package using standard tin/lead solders. The hermetic seal tube is gold plated to promote good on-site sealing and corrosion resistance. These assemblies are capable of easily creating a seal that meets industry hermeticity requirements.

PM fibers offer a means to control polarization of optical signals throughout the system, thus controlling Polarization Dependant Losses (PDL) and Polarization Mode Dispersion (PMD). This control is crucial in developing high speed, 40 Gbs, 100 Gbs coherent detection systems. In general, OZ Optics uses polarization maintaining fibers based on the PANDA fiber structure when building polarization maintaining components and patchcords. However OZ Optics can construct devices using other PM fiber structures. If necessary, OZ Optics is willing to use customer supplied fibers to build devices.

Key Features:

- High Polarization Extinction Ratios up to 30 dB

- Single or Multiple Fiber Designs up to 24 Channels

- Ribbon Fiber Versions Available

- Can be Installed into Packages with Standard Solders

- Gold Plated Seal Tube for Easy Sealability and Corrosion Resistance

- Terminated with Round or Rectangular Ferrules

- Designed to Meet Telcordia Rrequirements

- Custom Configurations Possible

Applications: Laser Diode Packaging; Waveguide Packaging; Integrated Optics Packaging; Vacuum Feedthrough Assemblies