mLC-C-1200-24-KIT mini Liquid Cooling Kit

mini Liquid Cooling Evaluation Kit; Cooling Capacity 1200 W @+25°C; Power Supply 24 VDC

Key Features:

Up to 1200 W Cooling Capacity

Ideal for Compact Cooling of Lasers or Bio Reagents

Compressor Speed Control for Ease of Temperature Control

Low Vibration, Low Noise

Lightweight, Compact

Easy to Integrate Kit to Interface With OEM Water Circuit and Electronics Control

Components Carefully Designed to Match Each Other

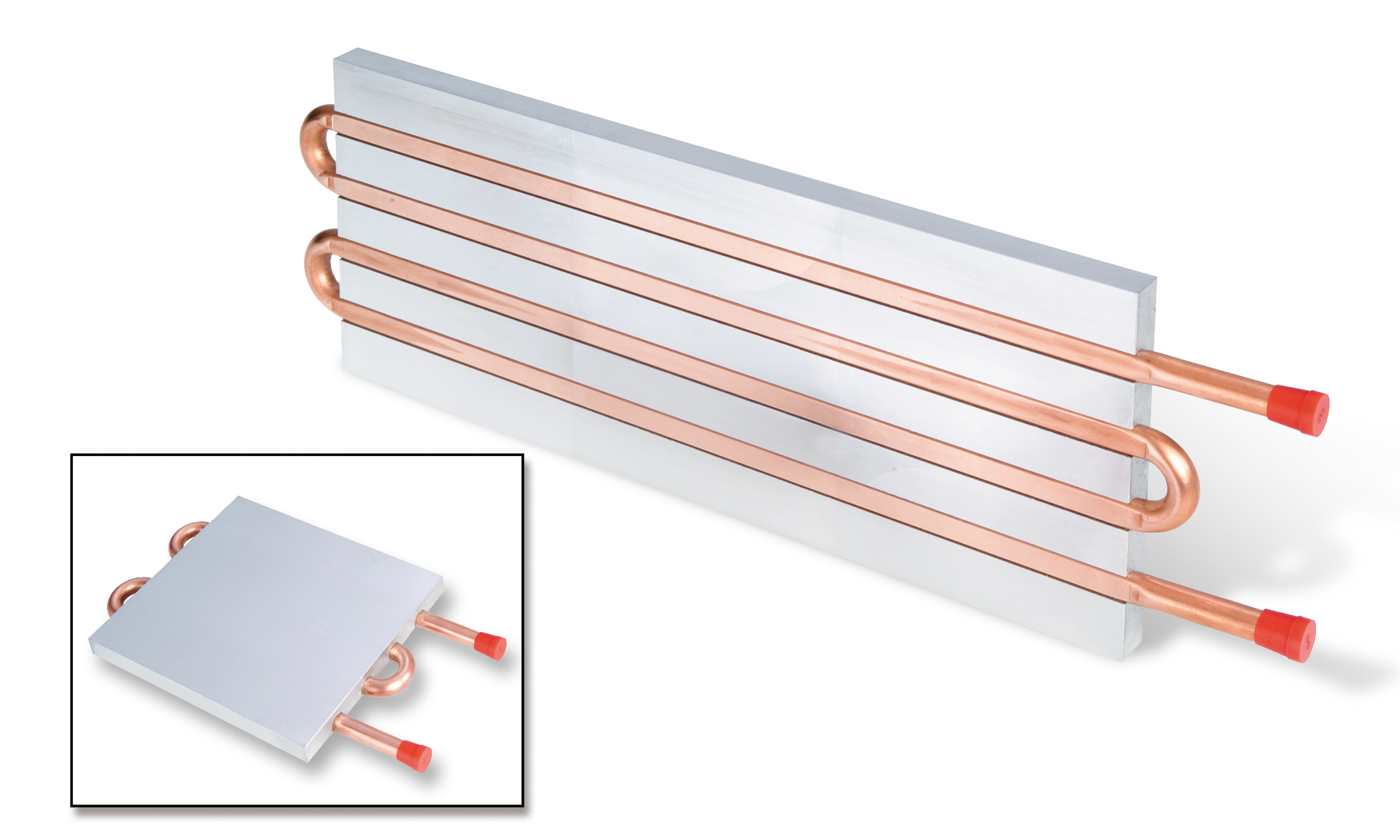

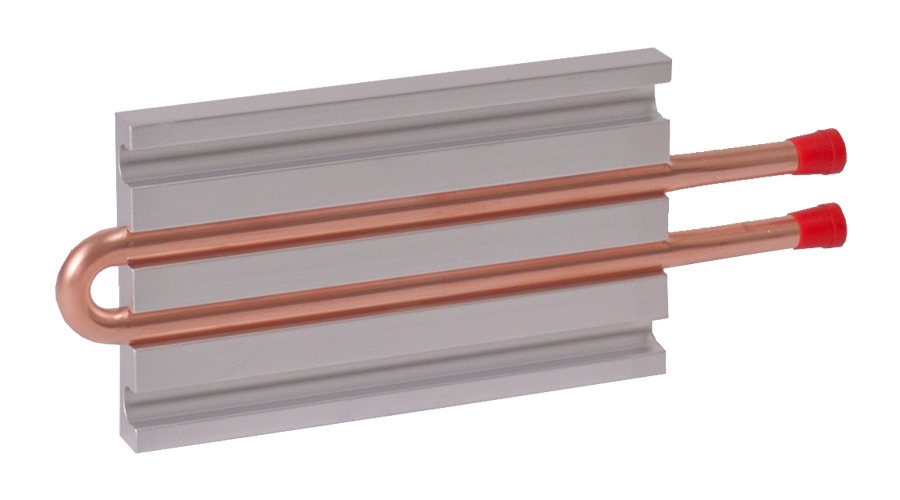

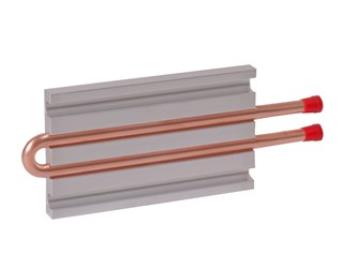

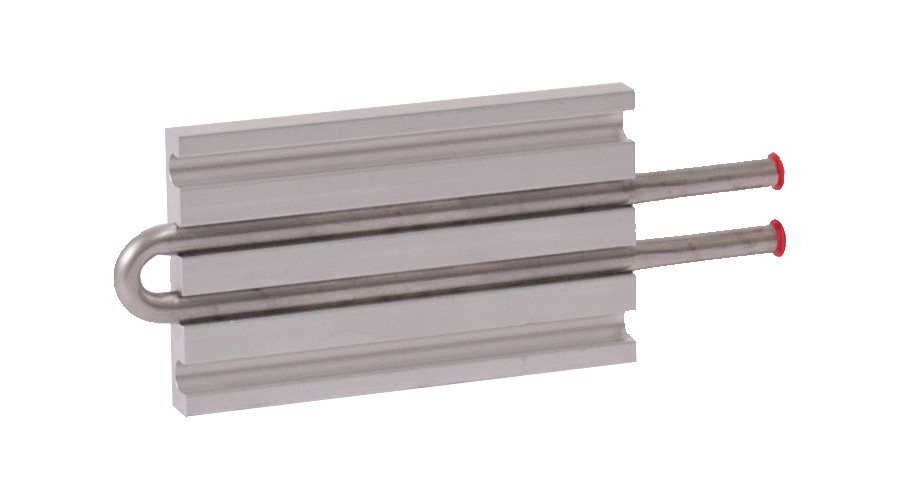

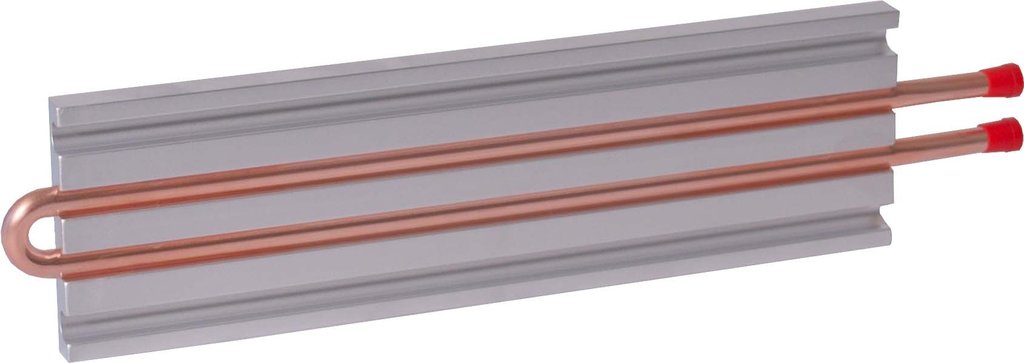

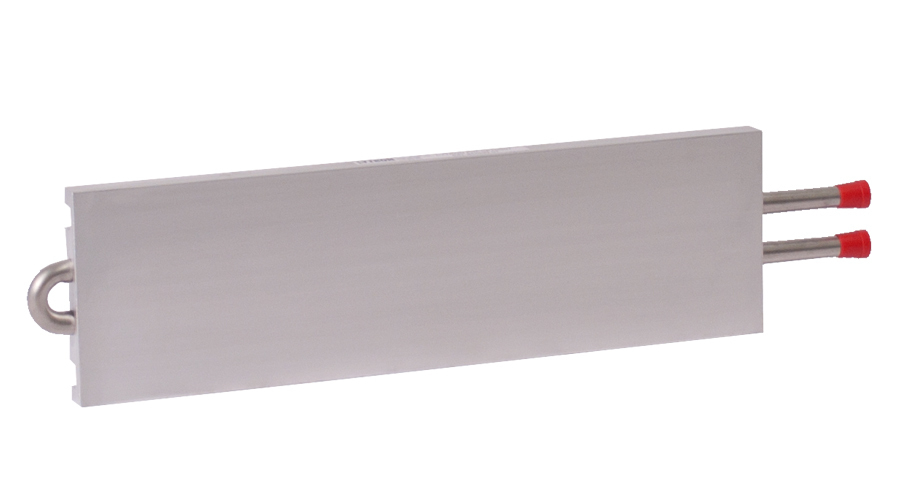

The mLC-C-1200-24-KIT is a sealed vapor compression circuit with a speed controlled miniature rotary BLDC compressor. The evaporator is a brazed plate heat exchanger, the interface to the customer liquid coolant circuit. The mLC-C-1200-24-KIT comes with the separate 24 VDC inverter board. The compressor speed can be set from the upper control system by frequency or analog signal. The mLC-C-1200-24-KIT’s condenser is an aluminum finned copper tube heat exchanger coil and must be cooled by forced convection, i.e. a 200 mm diameter fan or equivalent. The heat exchanger stainless steel plates are nickel brazed suitable for a variety of coolant fluids, such as water, DI water and glycol-water mixtures. The plate heat exchanger has male R ¼” connectors for the customer to connect its water circuit.For lower heat loads, we also carry a mLC-C-450-24-KIT with up to 450 W cooling capacity, or a Peltier-based mini Direct Cooling KIT providing up to 130 W with no liquids or moving parts (except fans). If you are looking for a ready-to-use recirculating chiller that includes the coolant loop, have a look at our family of mini Recirculating Chiller Kits (mRC-KITs) as well as our our other liquid cooling solutions offerings – or browse our large portfolio of liquid to air temperature management assemblies . Your customized liquid cooler: AMS Technologies’ thermal management specialists are happy to develop a liquid cooling solution tailored to your needs – based on Peltier or compressor technology – and offer all services from development and proof-of concept to series production. Get in touch with us now to discuss your customized liquid cooler.Specifications:

Cooling Capacity: Approximately 930 W (at 59 rps, Twater = +20°C, Tambient = +40°C) to 1760 W (at 90 rps, Twater = +20°C, Tambient = +20°C)

Power Supply Consumption: ≤720 W (30 A @24 VDC)

Temperature Range (Ambient, Operating): +15°C to +45°C

Hydraulic parameters: Pressure Drop 40 mbar @6 lpm, 100 mbar @9 lpm

Controller/Inverter Board: Operating Range 28 to 100 rps, Speed Command Square Wave Pulse Frequency 56 to 200 Hz, Variable Resistor Input 2.8 to 10 kΩ

Dimensions: 250 x 386 x 248 mm (WxHxD)

Weight: 10 kg

Applications: Compact Cooling of Lasers or Bio Reagents With up to 1200 W Cooling Capacity; Evaluation Kit to Interface With OEM Water Circuit and Electronics Control

Product number:

P000076-1

Manufacturer: