Filter

–

RAYLASE

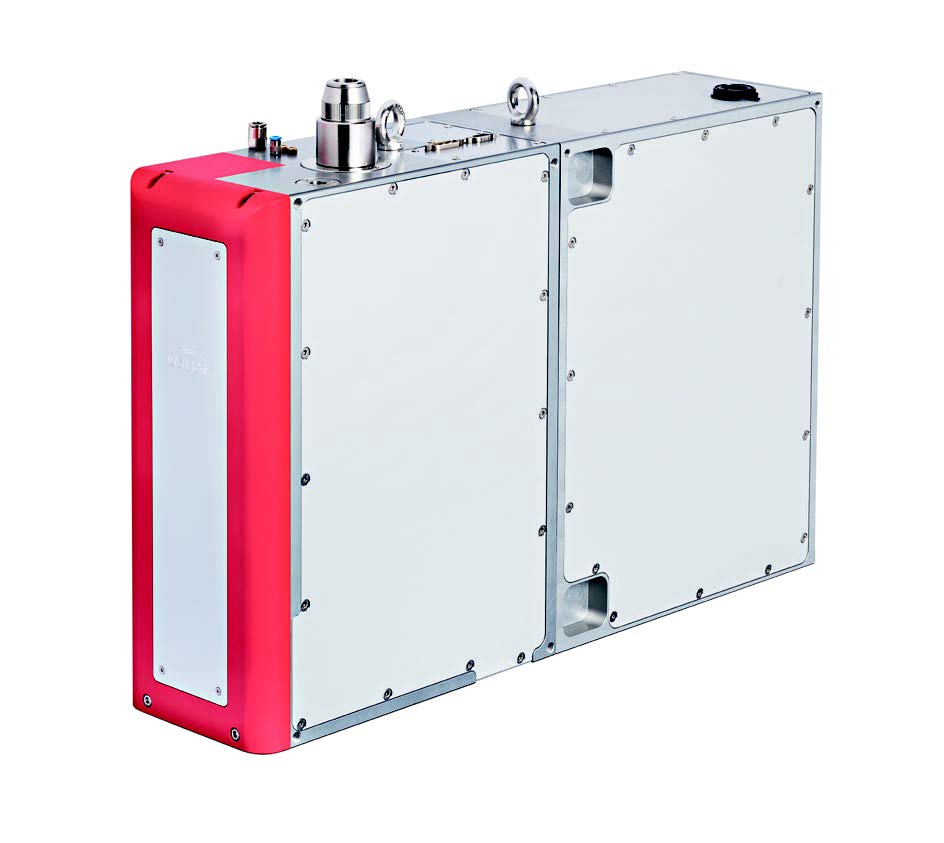

AM-MODULE NEXT GEN Prefocusing Deflection Units

Optical Deflection ±0.325 rad; Processing Speed 30 rad/s; Positioning Speed 30 rad/s; Digital Control via RL3-100 Protocol; Resolution 0.76 µrad

Raylase’s AM-MODULE NEXT GEN prefocusing deflection units for fiber-coupled lasers feature homogeneous power density and exceptionally low drift values. They enable ultra-dynamic, rapid processing with flexible spot diameters. Full digital, model-based control is ensured with absolute precision. Up to 4 modules can be operated simultaneously over one construction field. Direct connection of a photodiode or pyrometer for process control is also possible.

For more effective process monitoring, the BASE-Module can be expanded with the SENSOR-Module. The two integrated sensors not only ensure customized quality control, they also enable archiving and process control. Focus tracking is built-in for one of the sensors. Data can be preprocessed either directly in the expanded camera electronics or on a powerful frame grabber.

The AM-MODULE NEXT GEN prefocusing deflection units are available in two variants: As a standard module or a high-performance module with fully digitally galvo-scanner. The high-performance module is designed for use in the manufacture of ultra-high precision components which must satisfy particularly high safety specifications. This application is of particular interest for users in the aerospace industry, automotive manufacturing and medical engineering.

Key Features:

Fast Beam Deflection With Uniform Power Distribution Over the Entire Field

High Dynamic for 3D-Production of Metal Parts for Working Fields From up to 600 mm x 600 mm

Innovative Design for Effective Full Parallelization Over the Working Field

Direct Fiber Connection and Zoom Axis for Highly Dynamic Change of Spot Size

On-Axis Process Monitoring and Control Using Various Sensors With Focus Tracking

Control: Via RL3-100 Protocol 20 Bit

Optical Deflection (typ.): ±0.325 rad

Resolution RL3-100, 20 Bit: 0.76 µrad

Repeatability (RMS): <0.4, <2.0 µrad

Position Noise (RMS): <2.0, <3.2 µrad

Max. Temperature Drift: 8, 15 ppm/K Gain, 10, 15 µrad/K Offset

Long-term Drift (8 h): <50, <60 µrad, <30, <40 µrad (Water Temperature Control)

Beam Divergence: 80 to 140 mrad (Typ.), 90 to 150 mrad (Max.)

Tuning: Hatching (H)

Processing Speed: 30 rad/s

Positioning Speed: 30 rad/s

Tracking Error: 0.23, 0.25 ms

Step Response Time (@1% of Full Scale): 0.66, 0.70 ms

Tracking Error Focusing Unit: 1.5 ms

Speed of Moving Lens: 880 mm/s

Power Supply: +48 VDC, 6 A RMS, max. 10 A

Temperature Range: +15°C to +40°C

Protection: IP64

Dimensions: 284 x 150 x 393 mm (BASE Module), 315 x 150 x 393 mm (SENSOR Module), 589 x 150 x 393 mm (Total)

Weight: Approx. 15 kg (BASE Module), 14 kg (SENSOR Module)

Applications: Manufacturing of Ultra-high Precision Components With Particularly High Safety Specifications; Aerospace Industry; Automotive Manufacturing; Medical Engineering

Product number:

SW11865

Manufacturer:

RAYLASE

AXIALSCAN Prefocusing Deflection Units

Optical Deflection ±0.393 rad; Processing Speed 10-65 rad/s; Positioning Speed 10-65 rad/s; Max. Input Aperture 15, 20 mm; Digital Control via SL2-100, RL3-100, or XY2-100 Protocol

Raylase’s AXIALSCAN series of prefocusing deflection units offer very small spot diameters at large field sizes or processing areas, flexibility, high deflection speed, long-term stability and low drift values.

AXIALSCAN-20/-30 deflection units feature high power density in the spot, enabling new application and reduced system costs. Deflection units are designed for field sizes from 100 mm x 100 mm up to 1,800 mm x 1,800 mm. These units are available with options like motorized adjustment of the operating field steered by the stepper motor interface, high-power version with optimized Nd: YAG and CO₂ optics for up to 4 kW, as well as a high-speed version with double motor-driven Z-axis and extremely light and stiff high-performance mirrors.

The AXIALSCAN-30 DIGITAL II deflection units with the LT-II-15 digital linear translator module ensure exceptionally low drift values at 20 Bit position resolution. Heat development is greatly reduced thanks to the PWM output stages used. Thanks to optimized lenses for CO₂ wavelength and 1060 to 1070 nm, the AXIALSCAN-30 DIGITAL II HP deflection units can handle laser power up to 4 kW.

The pre-focusing deflection units of the AXIALSCAN-50 DIGITAL II series feature cutting-edge digital control electronics. Various tuning options are available, enabling application-specific adjustment of control parameters and, in combination with the SC mirrors, produce exceptional deflection speeds and dynamic values. The AXIALSCAN-50 DIGITAL II can be equipped with a range of tuning options (VC, LS and M). Default tunings are configurable.

The AXIALSCAN-FIBER 20/30 deflection systems can be easily integrated into any laser system by means of various mechanical interfaces below, to the side (robot flange is possible) and from above. The integrated fiber collimator enables connection of the laser fiber without beam path alignment. A second external protective window can be quickly and easily replaced, with optional monitoring available. Camera and welding monitoring systems can be adapted to the process light output without aberrations. The AXIALSCAN FIBER-30 is completely dust-proof and therefore ideal for use in a harsh industrial environment. Suitable mirrors are available both for high-performance welding applications with laser power in the multi-kilowatt range and for highly dynamic applications. Optical configurations are available for all standard beam parameters of lasers and their fibers.

The AXIALSCAN FIBER-50 deflection systems ensure that the laser process is highly dynamic and precise, even when the workpiece is passing under the deflection unit at varying speed. The pre-focussing deflection unit can, among other things, separate the contours of electrical connection surfaces (tabs) on batteries with precision during the foil winding process. This benefit is possible thanks to the pulsed laser beam – highly dynamic with position accuracy – that is directed from the AXIALSCAN FIBER-50 deflection unit onto the workpiece. It works with the smallest spot size on processing field sizes of between 300 x 300 mm and 850 x 850 mm.

Depending on the model, the AXIALSCAN deflection units are compatible to the XY2-100 (16 Bit) protocol, the SL2-100 (20 Bit) protocol, or the RL3-100 (20 Bit) standards. They can be digitally controlled by a control card, such as the SP-ICE-1 PCIe PRO or SP-ICE-3. Lenses, protective glass, scan mirrors, deflection mirrors and objectives with optimized mounts are available for all typical laser beam source types. We are happy to help you put together the perfect configuration for your application – get in touch with AMS Technologies to discuss your project’s requirements.

Key Features:

For Large Areas With Small Spot Size and 3D-Applications

For Applications at up to 5 kW Laser Power

High-speed Z-Axis With Double Motor Option (AXIALSCAN-20/-30) and Digitally Controlled (AXIALSCAN-30/50 DIGITAL II)

Control: Via SL2-100 Protocol 20 Bit, RL3-100 Protocol 20 Bit, or XY2-100 Protocol 16 Bit

Variable Processing Field Sizes: 100 x 100 up to 1,800 x 1,800 mm

Reduced Power Loss and Heat Development Due to Digital PWM Output Stages (AXIALSCAN-30 DIGITAL II)

Optimized long-term drift for highly challenging process quality (AXIALSCAN-30/50 DIGITAL II/HP)

Optional: Pilot laser function (AXIALSCAN-50 DIGITAL II)

Max. Input Apertures: 15, 20 mm

Optical Deflection (typ.): ±0.393 rad

Resolution XY2-100, 16 Bit: 12 µrad

Resolution SL2/RL3-100, 20 Bit: 0.76 µrad

Repeatability (RMS): <0.4, <2.0 µrad

Position Noise (RMS): <2.0, <3.2 µrad

Max. Temperature Drift: 8, 15 ppm/K Gain, 10, 15 µrad/K Offset

Long-term Drift (8 h): <50 to <100 µrad, <30, <40 µrad (Water Temperature Control)

Beam Displacement: 25.63 to 60 mm

Tuning: VC, H, M, FV, LS

Processing Speed: 10 to 65 rad/s

Positioning Speed: 10 to 65 rad/s

Tracking Error: 0.155 to 1.5 ms

Step Response Time (@1% of Full Scale): 0.54 to 1.9 ms

Power Supply: ±15 to ±18 VDC, 7.5 A RMS, max. 10 A, +30/+48 VDC, 4, 6 A RMS, max. 8, 10 A

Temperature Range: +15°C to +35°C

Protection: IP 54, IP64

Dimensions: 270 x 140 x 320 mm, 380 x 200 x 494 mm, 550 x 280 x 230 mm

Weight: Approx. 5.5 to 28 kg

Key Features AXIALSCAN-FIBER 20/30/50:

“High Power” Version for Welding in the E-mobility Market or “High Dynamic” Version for the Powder-bed Process (SLM) in Additive Manufacturing

4-times Productivity by Quadruple Design With 100 % Overlapping Above the Production Panel

Dust-proof and Tailored to the Requirements of Industrial Powder Bed Machines

Easy System Integration With Direct Laser-fiber Connection and Multiple Mounting Possibilities

“On-Axis” Quality Control by Integrated Process-monitoring Interface (AXIALSCAN-FIBER 50)

Wide Range of Options for Coaxial Inline Process Control (AXIALSCAN-FIBER 50)

Sharp and Precise Cutting of Battery Foils (AXIALSCAN-FIBER 50)

Applications: Scribing; Cutting; Perforating; Welding; Drilling; Marking-and-processing-On-The-Fly (MOTF) Applications; Bleaching; 3D Applications; Additive Manufacturing (SLM); Packaging Industry; Micro-material Processing; Processing of Moving Parts; E-Mobility; Welding of Bipolar Plates for Fuel Cells

Product number:

SW11866

Manufacturer:

RAYLASE

Deflection Unit Software

Definition of Laser Process Parameters; Creating Drill Patterns, Text Objects and Filling Structures; Bitmap Marking; Multiplying Container; Comprehensive Vector Editing; Pen Management/Assignment; Job Analytics; Integration of SP-ICE-3 Control Card

Raylase sees itself as a full-range supplier, offering a complete portfolio – from deflection units to control electronics and the corresponding laser processing software. Raylase’s deflection unit software makes tailor-made solutions possible and guarantees that machine manufacturers can drive their product development forward and venture into the high-performance arena. The resulting combination of lasers, laser deflection units and the corresponding software improves performance and reduces costs.

The RAYGUIDE software architecture is designed to respond quickly and flexibly to ever-changing and increasingly complex applications, while simultaneously guaranteeing a high degree of product stability. RAYGUIDE offers a wide range of features, and its functional scope will be enhanced on an ongoing basis to meet your growing requirements. For customers that want to access RAYGUIDE functions from their own user interfaces, Raylase offers a software development kit (SDK). This is a program library that also incorporates all the application benefits of RAYGUIDE. The interface is programmed in the Dot.Net environment.

The Multi-Point Editor is a software application for creating and editing RAYLASE correction files to adapt them to the individual opto-mechanical situation of each laser system. The correction files provided for your deflection unit by the manufacturer already take into account the respective wavelength, the aperture of the deflection unit, the working distance and much more. In this way, sufficient accuracies can be ensured for many applications.

Nevertheless, each system has individual tolerances. In addition, alignment errors occur during the setup of your system, which must be compensated for in order to achieve even higher accuracies in scan field calibration. Raylase provides you with the Multi-Point Editor software free of charge. You do not need a license to use it. NOTE: When using the RAYGUIDE laser process software, the Multi-Point Editor application is already included as an integral part.

Key Features RAYGUIDE:

Optically Innovative User Interface With User-defined Configuration of the Required Panels

Full Integration of the Raylase SP-ICE-3 Control Card

Equipped With Functions to Support all Existing and New Raylase Deflection Units

Definition of Laser Process Parameters

Creating Drill Patterns, Text Objects and Filling Structures

Bitmap Marking, Multiplying Container, Pen Management/Assignment, Job Analytics

Agile Architecture for Responding Quickly to New Requirements

Easy Integration into Automated Production Environments

Comprehensive Vector Editing: Powerful Toolbox to Optimize Vector Graphics

Integrate Part or the Complete GUI into Your Machine’s HMI

Use Plugins to Integrate Individual Functions into RAYGUIDE

Powerful Multi-point Editor Tool is Integral Component of RAYGUIDE User Interface

Manage Multiple Control Cards and Associated Deflection Units

Emulated Control Card Allows to Perform Many tasks Without Connecting a Control Card

Key Features MULTI-POINT-EDITOR:

Calibration of the XY Correction Values

Calibration of the Z Correction Values for the Third Optical Axis (if Available)

Creation of a Correction Table for the Local Adjustment of Laser Power

Creation of a Specially Defined Correction File by Entering Optical Parameters

Direct Marking of the Calibration Pattern (in Connection With the Use of a SP-ICE-3 Control Card)

Definition of a Sub-field (if Not the Whole Scan Field is Used)

Selection From Various Calibration Patterns

Direct Input of Scaling, Rotation, Offset and Trapezoidal Deviations

Import Function of Measured Values

Various Visualization Options of the Calibration Data for Validation of the Measured Values and Statistical Evaluation

Applications: Marking (Bitmaps, Text, Codes, Graphics); Welding; Cutting; Perforating; Surface Processing; MOTF Processing; Preparation for Stand-alone Operation With the SP-ICE-3 control card

Product number:

SW11869

Manufacturer:

RAYLASE

FOCUSSHIFTER Prefocusing Deflection Units

Optical Deflection ±0.393 rad; Processing Speed 30-200 rad/s; Positioning Speed 30-200 rad/s; Input Aperture 5, 10, 15 mm; Digital Control via SL2-100, RL3-100, or XY2-100 Protocol

Raylase’s FOCUSSHIFTER series of prefocusing deflection units provides tiny spot diameters with flexible focusing range in Z-direction. The modular, compact, robust, and pre-aligned design (CE) makes integration easy. Deflection units for Nd:YAG and CO₂ lasers are designed for field sizes from 100 mm x 100 mm to 300 mm x 300 mm. The field sizes are determined by the f-theta objective type. Submodule for other wavelengths are available upon request.

The FOCUSSHIFTER DIGITAL II deflection units provide flexible software-controlled focusing in the Z-direction, high deflection speed, long-term stability and exceptionally low drift values at 20 bit position resolution. Heat development is minimized as a result of the PWM output stages used.

The third dimension (3D) is not always the nonplus ultra. The FOCUSSHIFTER-14 deflection units deliberately take a (half) step backwards to significantly increase the range of applications for you as a machine builder or integrator in the fields of e-mobility, solar/photovoltaics, and electronics/IT. The FOCUSSHIFTER-14 cleans component contact surfaces (paint, oxide layers, oil, insulation), cuts flexible PCBs, glass displays or polarization foils, texturizes or structures a wide variety of surfaces and connect components, resistance-trims 5G antennas – all this in two and a half dimensions (2.5D) with automatically shifting the focus – generated by the f-theta lens – either downwards or upwards, allowing you to process different height levels of the same workpiece.

The deflection units are compatible with XY2-100 (16 Bit), SL2-100 (20 Bit) or RL3-100 (20 Bit). The units can be controlled digitally using a control card, such as SP-ICE-3 or SP-ICE-1 PCIe PRO, or via an analog current or voltage interface (FOCUSSHIFTER).

Lenses, protective glass, mirror substrates, coatings, and objectives with optimized mounts are available for all typical laser types, wavelengths, light densities, focal lengths and processing areas. This makes it possible to process a wide range of tasks to the highest quality standards and with optimized throughput. Using telecentric F-Theta lenses enables an almost vertical processing beam over the entire field. Customer specific configurations are also possible – we are happy to provide a customized configuration for your application, get in touch with AMS Technologies to discuss your project’s requirements.

Key Features:

Variable, Easy-to adjust Focus Range in Z-Direction

Modular and Compact Design for Easy Integration

Excellent Price-performance Ratio

Reduced Power Loss and Heat Development Due to Digital PWM Output Stages (FOCUSSHIFTER DIGITAL II)

Control: Via SL2-100 Protocol 20 Bit, RL3-100 Protocol 20 Bit, or XY2-100 Protocol 16 Bit

Available Input Apertures: 5, 10, 15 mm

Optical Deflection (typ.): ±0.393 rad

Resolution XY2-100, 16 Bit: 12 µrad

Resolution SL2/RL3-100, 20 Bit: 0.76 µrad

Repeatability (RMS): <0.4, <2.0 µrad

Position Noise (RMS): <2.0, <4.5 µrad

Max. Temperature Drift: 8, 15 ppm/K Gain, 10, 15 µrad/K Offset

Long-term Drift (8 h): <50 to <150 µrad, <30 to <100 µrad (Water Temperature Control)

Beam Displacement: 12.5 to 26.28 mm

Tuning: LN, RA, C, VC, H, M, MA, W

Processing Speed: 30 to 200 rad/s

Positioning Speed: 30 to 200 rad/s

Tracking Error: 0.10 to 0.9 ms

Step Response Time (@1% of Full Scale): 0.33 to 0.69 ms

Power Supply: ±15 to ±18 VDC, 7.5 A RMS, max. 10 A, +30/+48 VDC, 4 A RMS, max. 8 A

Temperature Range: +15°C to +35°C

Protection: IP 54, IP64

Dimensions: 202 x 159 x 150 mm, 330 x 105 x 134 mm

Weight: Approx. 5.3 to 7.5 kg

Applications: Deep Cutting; Deep Engraving; Deep Processing of Materials; In-glass Marking; Creation of 3D Images in Glass Blocks; Marking and Structuring at Various Heights; Cleaning Component Contact Surfaces of Paint, Oxide layers, Oil or Insulation; Cutting Flexible PCBs, Glass Displays or Polarization Foils; Texturizing or Structuring a Wide Variety of Surfaces and Connect Components; Resistance Trimming of 5G Antennas

Product number:

SW11867

Manufacturer:

RAYLASE

MINISCAN III 2-Axis Deflection Units

Optical Deflection ±0.393 rad; Processing Speed 30-100 rad/s; Positioning Speed 30-100 rad/s; Input Aperture 10, 14, 20 mm; Digital Control via SL2-100 or XY2-100 Protocol

Raylase’s MINISCAN III 2-axis deflection units offer very stable digital control, which further improves noise and drift values, thereby making the systems even more reliable and robust. Both the XY2-100 16 Bit and the SL2-100 20 Bit protocols can be used for digital control with the digital interface. A corresponding cable defines the use of the protocol.

Lenses, protective glass, and mirror substrates and coatings are available for many standard laser types, wavelengths, power densities, focal lengths and processing areas. This allows to handle a wide range of tasks with best quality and optimized throughput. Speed and dynamic responses are guaranteed, thanks to digital control and powerful PWM output stages.

We would also be happy to help you put together the perfect configuration for your application – get in touch with the AMS Technologies deflection experts now to discuss your project’s requirements!

Key Features:

Digitally Controlled, Low Noise and Drift

Control: Via SL2-100 Protocol 20 Bit or XY2-100 Protocol 16 Bit

Robust and Dust-proof for Industrial Applications

Various Mirror Substrates and Coatings for Marking, Hatching (AM SLM / SLS) and Cleaning

Available Input Apertures: 10, 14, 20 mm

Optical Deflection (typ.): ±0.393 rad

Resolution XY2-100, 16 Bit: 12 µrad

Resolution SL2-100, 20 Bit: 0.76 µrad

Repeatability (RMS): <2.0 µrad

Position Noise (RMS): <3.2, <4.5 µrad

Max. Temperature Drift: 15 ppm/K Gain, 10 µrad/K Offset

Long-term Drift (8 h): <80 µrad

Beam Displacement: 12.4, 17, 26 mm

Tuning: M, MA, VC, C

Writing Speed with High/Good Writing Quality: 600 to 1000 cps

Processing Speed: 30 to 100 rad/s

Positioning Speed: 30 to 100 rad/s

Tracking Error: 0.13 to 0.34 ms

Step Response Time (@1% of Full Scale): 0.30 to 1.01 ms

Power Supply: +30/+48 VDC, 2 A RMS, max. 5 A

Temperature Range: +15°C to +35°C

Protection: IP64

Dimensions: 100.0 x 77.0 x 81.5/83.0 mm, 134.0 x 98.0 x 100.3 mm, 145.0 x 116.0 x 103.5 mm

Weight (w/o Objective): Approx. 0.9, 2.0, 2.5 kg

Applications: Hatching of Surfaces in Additive Manufacturing with High Dynamic Performances; Ablation and Cleaning of Surfaces at High Speed; Challenging Marking Tasks

Product number:

SW11863

Manufacturer:

RAYLASE

SP-ICE-1/3 Deflection Unit Control Cards

Interface PCIe, 1-Gbps-Ethernet; Interface to Deflection Unit SL2-100, XY2-100, RL3-100; Resolution 16, 20 Bit; Output Step Period 10, 20 µs; Memory 1-32 GB

In addition to innovative electronic components built into its deflection units, Raylase’s electronics portfolio consists of intelligent control cards to drive the deflection units. These also function as an interface between software and mechanical systems with the capacity to control external machines.

The SP-ICE-1 PCIe PRO control card offers highest precision, flexibility, and easy integration. Windows-based DLLs are included. Scanning motion and laser control signals are precisely synchronized with the on-board processor unit. Dual buffering allows for downloading of the next job whilst executing the current job. The SP-ICE-1 PCIe PRO control card interfaces to the deflection unit via the XY2-100 standard/enhanced protocol. Laser control signals are: laser modulation, laser gate, first pulse suppression and lamp/diode current. Analog and digital signals are available. Buffered and unbuffered I/O ports are available for interfacing to external equipment.

The SP-ICE-3 control card is the universal solution for every laser system with deflection units. With its multiple individually configurable ports it fits everywhere, even at highly specific requirements. Thanks to the .NET programming environment and the flexibility of the SP-ICE-3 control card, a broad variety of applications can be solved quickly. The SP-ICE-3 controls up to 2 deflection units via the SL2-100 or RL3-100 protocol with 20 Bit position resolution and 10 μs step period. It can log up to 24 million measurements from the deflection unit. This allows for system optimization during development and continuous monitoring during operation. With its 1 GB RAM and a 32 GB MicroSD-card, users may upload and store numerous highly complex laser programs to the card at once. Five configurable I/O-ports with up to 24 bit, two quadrature decoders, a USB 2.0 and a RS232 interface make the SP-ICE-3 your central control unit for laser processes.

Key Features:

Micro SD Card With 4 GB On-board Memory (32 GB for SP-ICE-3)

Master-slave and Master-master Operation

Controls 2-, 3-, 4- and 5-Axis Deflection Units and All Common Laser Sources (SP-ICE-3)

Speed- and Position-dependent Laser Control (SP-ICE-3)

Marking-and-processing-On-The-Fly (MOTF, Optional for SP-ICE-1 PCIe PRO)

Interface to Deflection Unit: XY2-100 (16 Bit) Protocol Enhanced With Feedback Channel, SL2-100 and RL3-100 (20 Bit) Protocol (SP-ICE-3)

Interface to PC (Control): PCIe, 1-Gbps-Ethernet (SP-IC-3)

Resolution: 16, 20 Bit

Output Step Period: 10, 20 µs

Can be Used as External Control Card via Gigabit Ethernet (SP-ICE-3)

Applications: Driving of Raylase Deflection Units; Interface Between Software and Mechanical Systems; Control or External Machines

Product number:

SW11868

Manufacturer:

RAYLASE

SUPERSCAN 2-Axis Deflection Units

Optical Deflection ±0.393 rad; Processing Speed 25-200 rad/s; Positioning Speed 25-200 rad/s; Input Aperture 7-30 mm; Digital Control via SL2-100 or XY2-100 Protocol

The innovative thermal management and modular design make Raylase’s SUPERSCAN 2-axis deflection units the perfect solutions for demanding laser applications.

The “enhanced” option of the SUPERSCAN IIE models offers a 50 % better long-term drift performance. Long-term drift can even be further minimized by an additional water tempering. The SUPERSCAN IIE deflection units are compatible to the XY2-100 standard protocol. They can be digitally controlled by a control card, such as the SP-ICE-1 PCIe PRO.

The SUPERSCAN IV‘s model-based, digital regulation offers extremely dynamic responses and final speeds, which really come into play when used in MOTF-applications (Marking-and-processing-On-The-Fly) in conjunction with one of Raylase’s linear translator modules. The robust, water-cooled master block design, combined with optional air flushing, enables applications at up to 6 kW laser power.

The High-power welding module with the digitally controlled SUPERSCAN IV-30 2-axis deflection unit can be quickly and easily integrated into new or existing machine and production lines. This module with infrared (or, alternatively, green or blue) wavelength is an established piece of laser welding technology based on F-Theta lenses. With the High-power welding module, you, as a machine and plant manufacturer or integrator, are ideally positioned to meet customer requirements for very high laser power outputs with 100% process reliability.

This cost-efficient, modular laser welding application is ideally suited to industrial applications with a specified laser working field of up to 300 x 300 mm. These include, for example, welding of battery cell covers or tab welding, i.e. welding of cell contact surfaces made of aluminium or copper plates. The High-power welding module uses remote welding in combination with a robot. Deflection units with apertures of 20 to 30 mm ensure top-quality results during laser welding of metals and plastics.

A fully digital feedback control electronics inside the SUPERSCAN V models provides excellent dynamics and continuous monitoring of e.g. the position of the mirrors and their speed. Depending on the applied protocol (SL2-100 or XY2-100), the mirrors can be positioned with a resolution of up to 20 Bit. Thanks to the enormous acceleration and maximum speed of the digital galvanometers, the SUPERSCAN V also performs laser jobs with sharp edges extremely fast and precise.

Lenses, objectives with optimized mounts, protective glass, and scan mirror substrates and coatings are available for all typical laser types, wavelengths, power densities, focal lengths, working fields and processing areas. The control electronics of SUPERSCAN IV and V were designed to be flexible to enable the configuration of additional sets of control parameters (tuning options). Customer specific configurations are also possible – get in touch with AMS Technologies to discuss your project’s requirements!

Key Features:

Lowest Drift Values Through Twin-shell Design

Suitable for High-power Applications

Water Tempering and Air Flushing Options

Reduced Power Loss & Heat Development Due to Digital PWM Output Stages (SUPERSCAN IV)

Dynamic Response & High Speed for Maximum Productivity in MOTF Applications (SUPERSCAN IV)

High-speed Scanning up to 66 m/s to Ensure High Throughput >3600 Wafers per Hour (SUPERSCAN IV SOLAR)

High Accuracy <±15 µm to Ensure High Cell Efficiency (SUPERSCAN IV SOLAR)

Minimal Drift and Extremely Low Noise Due to Digital Encoder Technology (SUPERSCAN V)

Extreme Accelleration and Precise Laser Guidance for Sharp Corners and Edges (SUPERSCAN V)

Wide Range of Mirror Substrates and Coatings for Diverse Applications

“Enhanced“ Option for 50 % Improved Long-term Drift (SUPERSCAN IIE)

Available Input Apertures: 7, 10, 12, 15, 20, 30 mm

Control: Via SL2-100 Protocol 20 Bit or XY2-100 Protocol 16 Bit (Depending on Model)

Optical Deflection (typ.): ±0.393 rad

Resolution XY2-100, 16 Bit: 12 µrad

Resolution SL2-100, 20 Bit: 0.76 µrad (SUPERSCAN IV)

Repeatability (RMS): <0.4, <2 µrad

Position Noise (RMS): <2.0 to <10 µrad

Max. Temperature Drift: 8, 15 ppm/K Gain, 10, 15 µrad/K Offset

Long-term Drift (8 h): <50 to <150 µrad, <30 to <100 µrad (Water Tempering)

Beam Displacement: 9.0 to 35.98 mm

Acceleration Time: 0.19 to 0.90 ms

Writing Speed: 350 to 900 cps

Processing Speed: 25 to 200 rad/s

Positioning Speed: 25 to 200 rad/s

Tracking Error: 0.10 to 400 ms (SUPERSCAN IV)

Step Response Time (@1% of Full Scale): 0.33 to 1.2 ms (SUPERSCAN IV)

Power Supply: ±15 to ±18 VDC, 3 A RMS, max. 10 A (SUPERSCAN IIE), +30/+48 VDC, 2 A RMS, max. 5 A (SUPERSCAN IV, V)

Temperature Range: +15°C to +35°C

Protection: IP64 (SUPERSCAN IV), IP 65 (SUPERSCAN V)

Dimensions: 135.0 x 97.0 x 102.0 mm to 203.0 x 159.0 x 160.5 mm

Weight (w/o Objective): Approx. 1.6 to 5.9 kg

Applications: Scribing; Marking; Ablation; Welding; ITO Structuring; Wafer Structuring in the Solar Industry; Drilling or Structuring of Semiconductor Wafers, Medical Products and Security Features of Documents and Chip Cards; Ag Patterning; Perforation and Cutting of Plastic Sheets and Paper Webs

Product number:

SW11864

Manufacturer:

RAYLASE

Founded in 1999, RAYLASE offers high-precision opto-mechanical components for fast deflection and modulation of laser beams. These comprise top-quality optical elements, galvanometer scanners acting as 2-axis deflection units or 3D prefocusing deflection units, as well as digital control electronics with an intuitive software interface. Customers across the globe rely on the unique performance and reliability of the deflection units that enable more flexible, economical, and precise material processing.

These components form the cornerstone of industrial laser systems for scanning printed codes, marking textiles and surfaces, welding metal plates and plastics and cutting and drilling semiconductor wafers and many other materials, including metal, plastic, paper, textiles, glass and others. Based in Wessling near Munich, Germany, RAYLASE also develops and manufactures intelligent solutions with machine vision for better calibration, simple automation, and exact monitoring of a range of laser processes and for additive manufacturing.