Product information "Beamsplitters & Combiners"

PM or SM Splitters/Combiners; 1550 nm, Other; Splitting Ratio 50/50-90/10; PDL ±0.25 dB; Directivity >50 dB

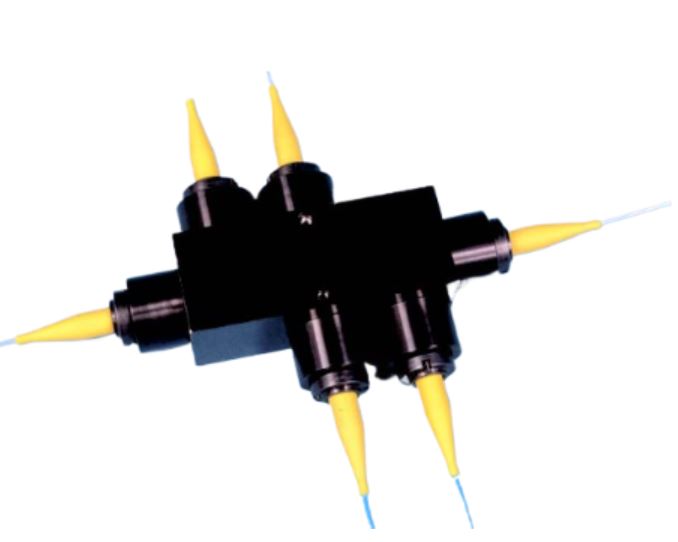

OZ Optics’ fiber optic beamsplitters are used to divide light from one fiber into two or more fibers. Light from an input fiber is first collimated, then sent through a beam-splitting optic to divide it into two. The resultant output beams are then focused back into the output fibers. Both 1xN and 2xN splitters can be constructed in this fashion with as many as eight or more outputs, with both low return losses and low insertion losses.

Standard parts available in this series are FOBS-12P (1x2) and FOBS-22P (2x2) pigtail-style splitters, FOBS-12 (1x2) and FOBS-22 (2x2) receptacle-style splitters, as well as LDBS-12P (pigtail-style) and LDBS-1 (receptacle-style) laser diode to fiber splitters, and finally ULBS-12P (pigtail-style) and ULBS-1 (receptacle-style) laser to fiber splitters

This design is extremely flexible, allowing to use different fiber types on different ports, and different beamsplitter optics inside. Custom designs combining circulators, polarizing splitters and non-polarizing splitters in the same package are routinely manufactured. Splitters can be made with either fibers permanently attached to each port (pigtail style) or with receptacles on each port that one can plug your fiber into (receptacle style). OZ Optics can also build source to fiber couplers with built-in beamsplitters for either laser or laser diode sources. Contact AMS Technologies for details.

If size is a concern, we recommend that you consider OZ Optics’ miniature line of splitters.

Within OZ Optics’ series of beamsplitters and combiners, the two most common types of splitters offered are polarizing beamsplitters and polarization maintaining (PM) beamsplitters. Polarizing beamsplitters split incoming light into two orthogonal states. They can also be used to combine the light from two fibers into a single output fiber. When used as a beam combiner, each input signal will transmit along a different output polarization axis.

PM splitters use a partially reflecting mirror to transmit a portion of the light from the input fiber to the main output fiber and reflect the remainder of the light to the second output fiber. All ports made using polarization maintaining fiber are aligned so that polarized light aligned parallel to the stress rods on the input fiber emerges from the output fibers in the same manner, maintaining the polarization state to a high degree. Splitters that only split off a small portion of the input light are commonly known as taps and often used for power monitoring applications. For a very cost-effective alternative configuration, combining the functions of a tap and monitor photodiode in a single unit, we invite you to review OZ Optics’ OPM series of inline optical taps and monitors.

Key Features:

- High Power Handling

- High Extinction Ratio

- Highly Modular and Flexible Design

- Wide Wavelength Range

- Bi-directional

- Broadband Performance

- Custom Designs Welcomed

- Mode-independent Behavior in Multi Mode (MM) Fiber Applications

- Splitting Ratio: 50/50 Standard, Custom Split Ratios 50/50 to 95/5 Available on Request

- Splitting Ratio Tolerance: ±3% (50/50 Splitters), ±2% (90/10 Splitters)

- Central Wavelength: 1550 nm Standard, Other Wavelengths on Request

- Bandwidth: ±1.5% of Central Wavelength

- Wavelength Dependent Loss (WDL): 0.1 dB (1520-1570 nm)

- Polarization Extinction Ratio: 20 dB Min., 23 dB Typ. (630-1600 nm), 17 dB Min., 20 dB Typ. (400-630 nm)

- Polarization Dependent Loss (PDL): ±0.25 dB

- Directivity: >50 dB

- Return Loss (RL): 30 dB to 60 dB

- Insertion Loss (IL): <0.5 dB to <1.0 dB

- Power Handling: >1 W (+30 dBm)

- Operating Temperature Range: 0°C to +70°C

Applications: EDFA Amplifier; Raman Amplifier Combiner; Polarization Mode Dispersion Compensation; Polarization Extinction Ratio (PER) Measurements; Fiber Optic Sensors; Coherent Communication Systems; Quantum Cryptography; Return Loss (RL) Measurement