NOA 81 Optical Adhesive 10g syringe

€24.47*

Available in 15 days, delivery time 1-2 days

Product information "NOA 81 Optical Adhesive 10g syringe"

Refractive Index 1.56; Viscosity at 25°C 300 cps

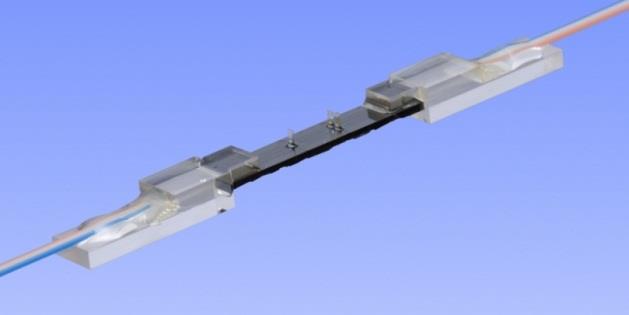

Norland Optical Adhesive 81 ("NOA81") is a single component liquid adhesive that cures in seconds to a tough, hard polymer when exposed to ultraviolet light. It is recommended as an extremely fast and efficient way to precisely bond optical components or fiber optics. It can be cured in a thin layer between two transparent substrates or applied as a dropto form a bridge between two components. Exposure to UV light quickly cures the adhesive and holds the components in place.

The outstanding characteristic of this adhesive is its extremely fast cure. Thin films can be initially set in under 10 seconds and thick films in 20 seconds using the light sources listed below. It is also extremely stable when not exposed to UV light. NOA 81 will not gel up in dispenser tips or cure before you want it to.

Typical Properties of NOA 81

| Solids | 100% |

| Elongation at Failure | 25% |

| Modulus of Elasticity (psi) | 200,000 |

| Tensile Strength (psi) | 4,000 |

| Hardness - Shore D | 90 |

Shelf life of the liquid is at least 6 months from the date of shipment if stored in a cool (5-22° C), dark place in the original container. If refrigerated, allow the adhesive to come to room temperature prior to use.