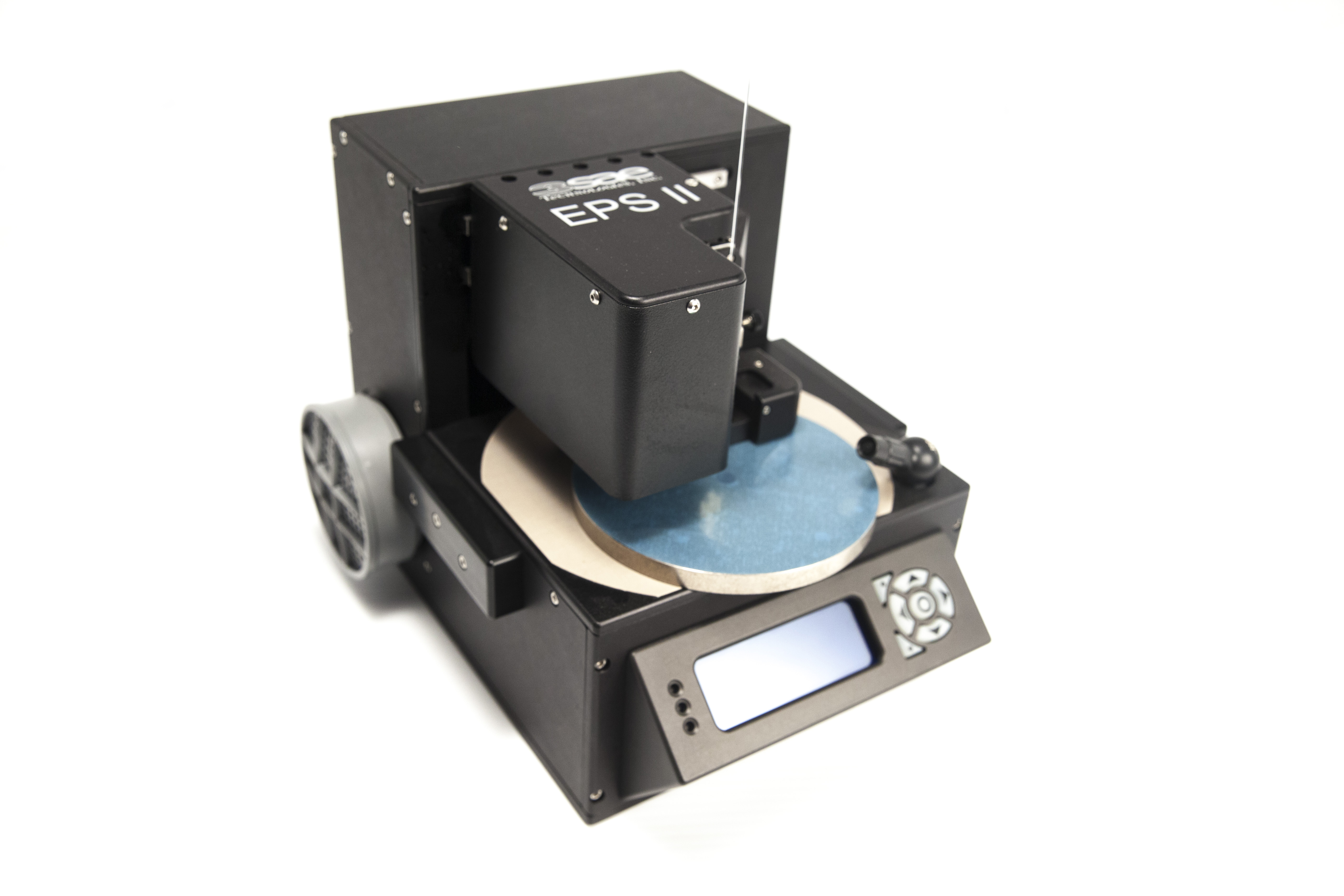

Product information "ProView XD Fiber End Face Interferometers"

For Fiber Holders or Connectors; Fiber Cladding/End Face Diameter 220-1200 µm; FOV ~1300 µm; Sensor CMOS Monochrome; Resolution 2560x1920; Interface & Power Supply USB 3.0

NorthLab´s ProView XD™ series are a highly advanced interferometer for precise measurement and inspection of fiber end faces with cladding diameters from 250 to 1200 μm. The interferometers are specifically designed for production lines where a simple, fast and very accurate end face inspection is required. The ProView XD series are also well suited for R&D environments and for fiber cleaver or connector maintenance purposes.

ProView XD interferometers are available in two variants for either fiber holders or connectors. ProView XD for fiber holders has a unique fiber clamping mechanism which can accommodate standard fiber holders from Fitel or Fujikura but also allows the use of bare fibers. This ProView XD model is delivered with a universal sized v-groove clamp assembly, while the ProView XD for connectors is delivered with a pre-mounted standard SMA, FC/PC, ST/PC or LD80 connector holder. Custom made clamps or adapters can be offered on request.

In many cases an interferometric fringe pattern can be very complicated to analyze and understand. For ease of use and optimal inspection speed the ProView XD series includes highly advanced and fully automatic functions for 2D and 3D topographic analyses of the end face surface. The software automatically indicates the angle, flatness and slope direction (radius and angle for the connector version) of the end face.

To simplify the inspection process even further the ProView XD interferometers can be set to a “Pass/Fail” mode. This function allows the operator to simply determine the end face quality via color codes on the image.

In addition to cleave angle or radius and angle inspection, the ProView XD series can also be used to measure several other properties such as fiber diameters and distance between defined points etc.

The ProView XD series has a compact design which makes it ideal for a production bench and to be used side-by-side with fusion splicers, cleavers, polishing stations, ultrasonic cleaners and other preparation tools. ProView LD interferometers are connected and powered via an USB 3.0 cable and hosted by an external PC (not included).

Key Features:

- Two Variants for Fiber Holders or Connectors

- Fiber Cladding or End Face Diameters: 220 to 1200 μm

- 2D and 3D Topography

- Fringe & Inspection Mode From PC Controller GUI

- Very Fast Inspection Time With Automatic Angle Estimation

- Optional Use of Pass/Fail Cleave Angle Indication (Radius and Angle for the Connector Version)

- Inspection of End-face Properties such as Flatness, Perpendicularity, Hackles and Contamination

- Grab and Save 2D and 3D Images and Cleave/Connector Data

- Field of View (FOV): ~1300 µm

- Sensor: CMOS Monochrome

- Resolution: 2560 x 1920

- Interface and Power Supply: USB 3.0

Application: Interferometric Inspection of Fiber End Faces with Diameters of 220 to 1200 µm