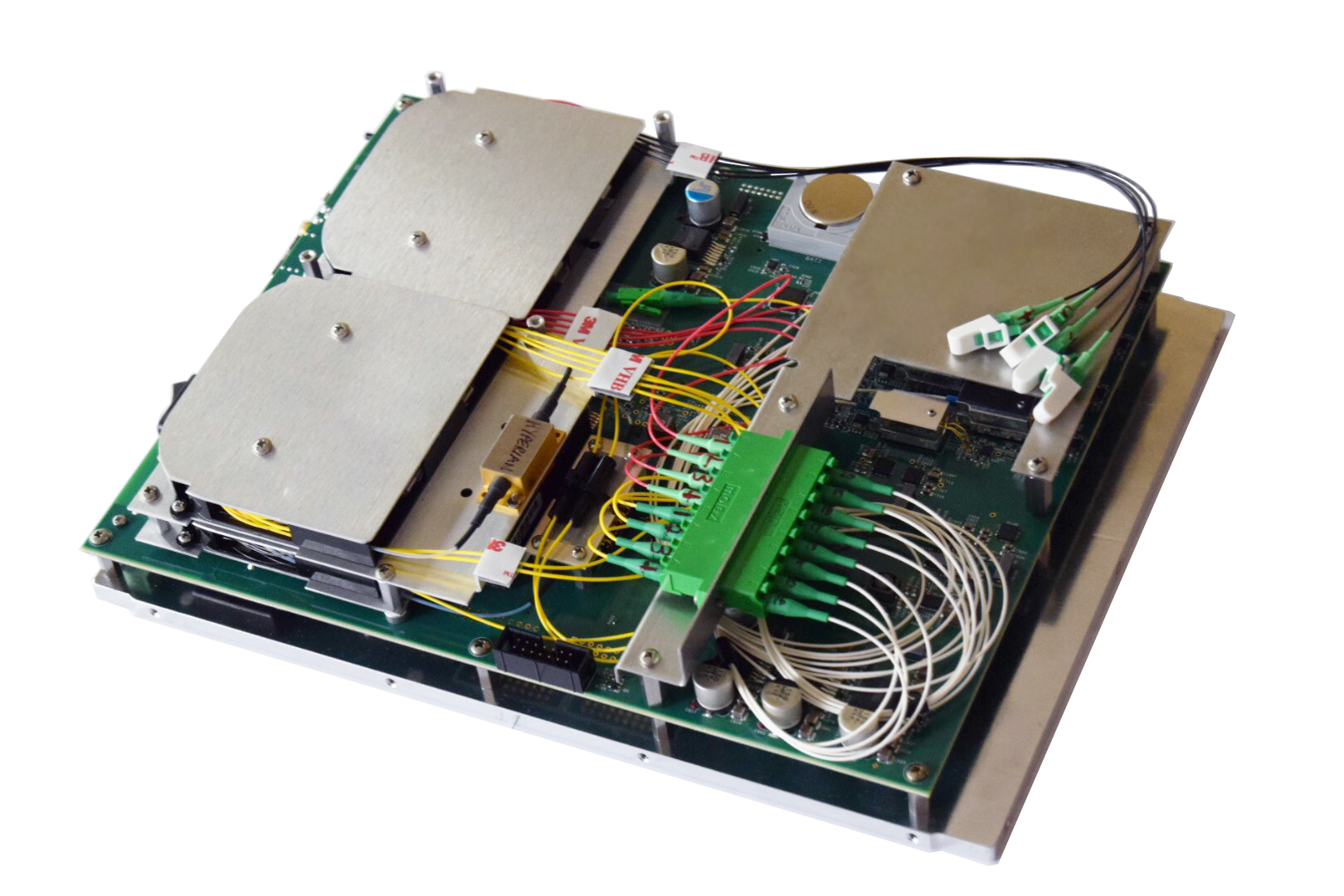

Product information "ODiSI 6000 Fiber Optic Sensing Interrogators"

1-8 Channels; Max. Sensor Length/Channel 10, 50 m; Measurement Points/m 384, 768, 1,538; Measurement Rate 10-250 Hz; Strain Measurement Range ±12,000 µɛ; Temperature Measurement Range -40 to 200 °C

Luna’s ODiSI 6000 series of optical distributed sensor interrogators are innovative measurement systems specifically designed to address the test challenges of 21st century advanced materials and systems. The systems provide thousands of strain or temperature measurements per meter of a single high-definition fiber sensor.

The high-definition data can fully map the contour of strain for a structure under test or the continuous thermal profile of a process in real time. Sensors are flexible, low-profile, require no electrical source, and can be bonded to sharply curved surfaces, embedded withing structures, or mounted directly to electrical surfaces.

An ODiSI 6000 series system comes configured with 1, 2, 4 or 8 channels able to measure standard Rayleigh HD-FOS sensors. In standard mode, each channel supports an HD-FOS sensor up to 10 m in length. With the extended range option, up to four channels can support sensors up to 50 m in length each.

The ODiSI 6000 series can be configured to measure strain or temperature with a gage pitch (spacing of adjacent gage centerpoints) of 0.65 mm, 1.3 mm or 2.6 mm. When configured for a gage pitch of 0.65 mm, the system acquires 1,538 strain or temperature measurement points along every meter of the HD-FOS sensor.

The ODiSI 6000 system is able to measure HD-FOS data at rates up to 250 Hz. The per-channel measurement rate will depend on several factors, including number of channels, gage pitch and sensor length. See specifications in the downloadable data sheet for more information on real-time measurement rates.

Key Features:

- Single- or Multi-channel Measurements of Strain-multiplex: Over 300,000 Measurement Locations

- Flexible, Lightweight and Easy to Install Sensors Reduce Time to First Measurement

- Passive, Corrosion Resistant, Dielectric, Flexible Sensors Go Where Other Sensors Can’t – in Bends, Around Corners, Embedded Inside Materials

- Long Sensor Life – No Drift or Recalibration Required, Cycle Counts >107

- Large Strain Range and High Resolution Allow for Mapping of Complex Strain Fields and Large Strain Gradients

- Number of Parallel Channels: 1 to 8

- Maximum Sensor Length Per Channel: 10, 50 m

- Measurement Points Per Meter of Sensor: 384, 768, 1,538

- Measurement Rates: 10 to 250 Hz

- Strain Measurement Range: ±12,000 µɛ

- Strain Measurement Resolution: 1 µɛ

- Temperature Measurement Range: -40 to 200 °C

- Temperature Measurement Resolution: 0.1 °C

- Dimensions: 340 x 350 x 110 mm

Applications: Characterize Strain on/in New Materials and Complex Structures; Profile Temperature In-situ to Maximize the Efficiency of Critical Processes; Measure Two – and Three – Dimensional Strain Fields to Validate FE Models; Evaluate Multi-material Joining; Embed Sensors Within Materials to Create “Smart Parts”