Downloads

Product information "AT3862P 5g Adhesives and Sealants"

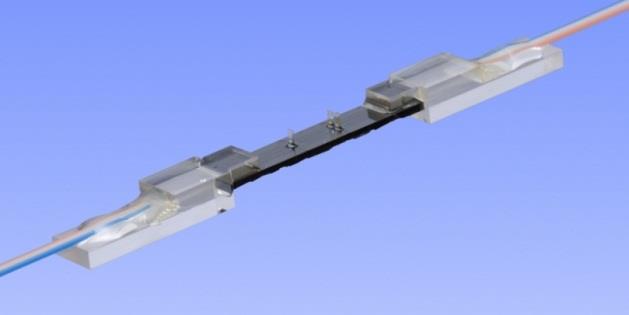

Adhesive;High Precision;Epoxy;5g

Properties "AT3862P 5g Adhesives and Sealants"

| Main Ingredient: | epoxy |

|---|---|

| Used in: | High Precision |

| Viscosity: | 500(mPa*s) |

| Weight: | 5g |

Manufacturer "NTT-AT"

The Japanese company NTT Advanced Technology Corporation (NTT-AT) was founded in 1976 as a subsidiary of the NTT Group, the largest telecommunication provider in Japan. Its business now covers almost the entire range of the information and communication technologies. NTT-AT is ISO 9001 certified.

NTT-AT’s products available from AMS Technologies include cleaning tools that reliably remove even the smallest contamination from end faces of optical fiber connectors, adapters or ferrules, but also fiber optics polishing films and equipment, various types of optical adhesives, ceramic micro heaters, swept light sources, varifocal lenses, KTN deflector modules or UVC LED modules and sterilization equipment.

Related links of the manufacturer