Modular Laser Micromachining: A Scalable Platform for Precision Manufacturing

Laser micromachining has become a key enabling technology in high-precision manufacturing. Its ability to process a wide range of materials like metals, glass, polymers, and composites with minimal thermal impact makes it indispensable across sectors such as electronics, medical devices, photonics, and automotive. However, as production environments evolve toward greater variability and customization conventional, single-purpose laser systems have their limitations.

The Role of Pulse Duration in Precision

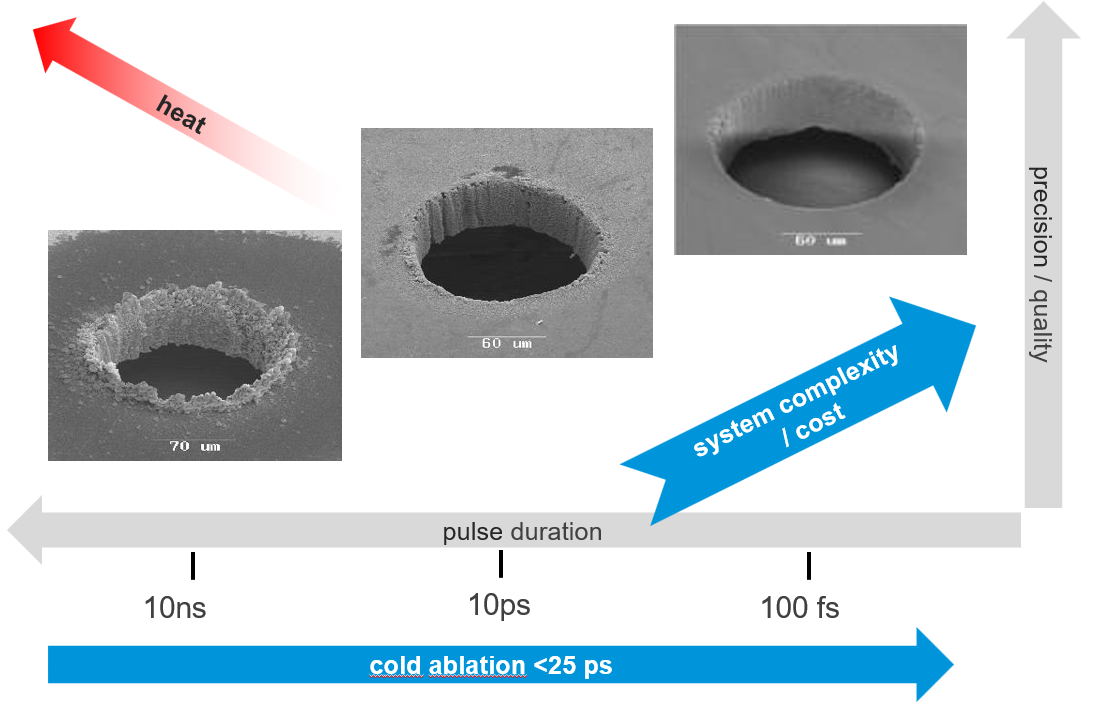

The quality of a laser micromachining application is closely tied to the duration of its laser pulses. Shorter pulses, such as those in the picosecond or femtosecond range, enable finer feature resolution, reduced heat-affected zones, and improved edge quality. These characteristics are essential for applications requiring high dimensional accuracy and minimal material distortion.

However, systems optimized for ultra-short pulses are typically expensive and highly specialized. They are often configured for a single application and lack the flexibility to adapt to new tasks or materials. Furthermore, the introduction of new equipment into a production line frequently necessitates extensive operator training. Given the current shortage of skilled technicians in many regions, this requirement can pose a significant operational challenge and create additional costs.

Do you want to discuss more? Contact us!

A Modular and Reconfigurable Alternative

To address these constraints, AMS Technologies and OpTek Systems have developed a modular laser micromachining platform that combines the ease of a turnkey solution with the adaptability of a fully customizable system.

This approach is based on a standardized architecture comprising interchangeable modules, including laser sources, beam delivery systems, and motion control units. Each module is designed to integrate seamlessly with the others, sharing a common mechanical footprint and software interface. This modularity allows users to configure systems tailored to specific application requirements while maintaining consistency in operation, control, and maintenance.

Proof-of-Concept Demonstration

The first proof-of-concept system will be presented at Laser World of Photonics 2025. This prototype is based on the OpTek MM2500 laser machine, equipped with a neoLASE MOPA laser capable of operating at multiple pulse durations. Future iterations of the platform will support reconfiguration of additional laser parameters, such as wavelength, output power, and beam shape.

This development represents a significant step toward a truly reconfigurable micromachining system. It enables manufacturers to respond more effectively to changing production demands, test new processes, and scale capabilities without the need for entirely new equipment.

Platform Benefits

The modular platform offers several key advantages.

First, it provides a high degree of flexibility without compromising usability. The system is delivered as a turnkey solution, yet it can be reconfigured or upgraded as requirements evolve. This reduces the need for multiple dedicated machines and lowers capital expenditure over time.

Second, the unified software and hardware architecture simplifies operator training and system integration. Because all modules operate within the same control environment, the learning curve is significantly reduced, which is particularly beneficial in settings where skilled labor is limited.

Third, the platform is inherently scalable. Users can begin with a basic configuration, such as a nanosecond laser, and later upgrade to picosecond or higher-power modules without replacing the entire system. This scalability supports long-term investment planning and operational agility.

Finally, maintenance and service are streamlined through the use of standardized components. This reduces downtime, simplifies spare parts management, and enhances overall system reliability.

Do you want to discuss more? Contact us!

Application Versatility

The platform is suitable for a wide range of micromachining applications. These include micro-drilling of metals and ceramics, precision cutting of polymers and composites, surface texturing for medical implants, and engraving of transparent materials such as glass. It is also well-suited for structuring thin films and coatings. Its adaptability makes it particularly valuable in high-mix, low-volume (HMLV) production environments, where the ability to quickly switch between different materials and geometries is essential.

Conclusion

As manufacturing continues to demand greater precision, flexibility, and efficiency, the limitations of traditional laser systems are becoming more pronounced. The modular, reconfigurable platform developed by AMS Technologies and OpTek Systems offers a forward-looking alternative. By combining the strengths of turnkey systems with the adaptability of modular design, it provides a scalable, future-proof solution for modern micromachining challenges. This approach enables manufacturers to remain competitive in dynamic markets, reduce operational complexity, and extend the lifecycle of their capital investments, while maintaining the high standards of precision that advanced applications require.