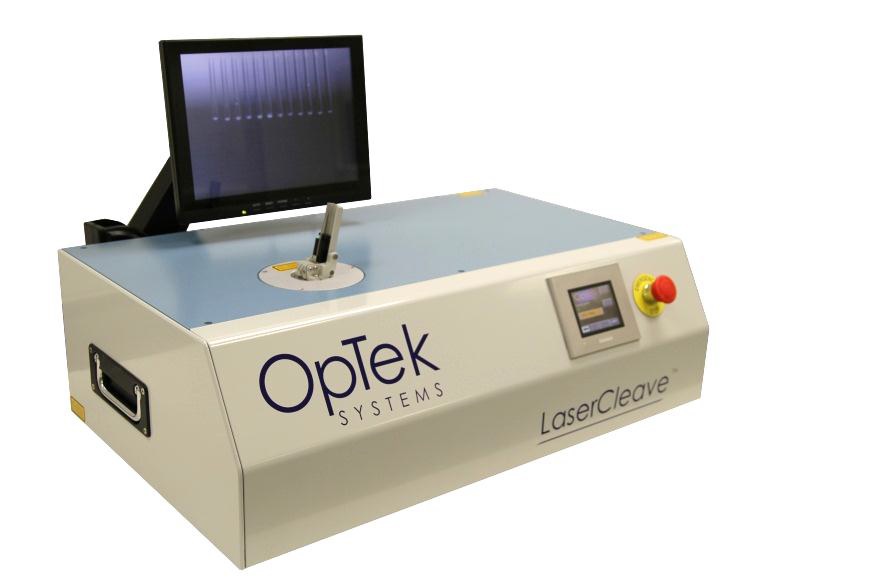

Product information "LaserCleave™-1500 Laser Cleavers"

Power Supply Single Phase, 1.7 kVA; Air Cooled; Integrated Viewing Cameras; Dimensions 756x505x245 mm; Weight 35 kg

OpTek Systems’ LaserCleave™-1500 series are tabletop fiber processing tools for optical interconnect production.

Within this series, two versions are available:

- LaserCleave™-1500 for single- and multi-fiber connectors

- LaserCleave™-1500 LT for LightTurn and MXC connectors

Engineered to address the production of existing and a new generation of optical interconnects in a compact and user friendly platform, LaserCleave™ systems are designed to maximise productivity in connector manufacture.

LaserCleave™ production tools from OpTek Systems are built around the technology that has been relied on in performance critical, volume production of optical fiber components since the mid 1990’s. OpTek’s unique machine tools are in service around the world producing laser-processed fiber ends of unmatched quality and reproducibility, with many millions of OpTek-processed ends in service in telecoms, datacoms, medical, aerospace and defence applications.

Key Features:

- Interchangeable Fixture for a Wide Range of Connector Types

- Rapid, Non-contact Process

- Cuts Fiber and Epoxy Close to Pedestal

- Accurate and Repeatable Cut-off Length or Cleave Position

- Control Over Fiber End Geometry

- No Core-cracks, Chipping, Scratching or Hackle

- Minimize or Eliminate Post Cleaving Operations

- Reduced Overall Cost of Terminations

- Electrical Supply: Single Phase, 1.7 kVA

- Cooling: Air Cooled, Water Cooling Option

- Vision: Integrated Viewing Cameras

- Shards: Capacity Collection >1M Fiber Shards

- Dimensions: 756 x 505 x 245 mm

- Weight: 35 kg

Applications: Production of Optical Interconnects; Maximise Productivity in Connector Manufacture; Production of Optical Fiber Components; Telecoms; Datacoms; Medical; Aerospace; Defence