Product information "Filters and Mirrors for Laser Applications"

The use of lasers as the illumination source for fluorescence applications requires special consideration for the optical path. This special attention centers on the coherent nature of the light, the small beam diameter, the polarization, and the power. There are also circumstances where cone angle and scatter within the system play significantly into the design of the optics.

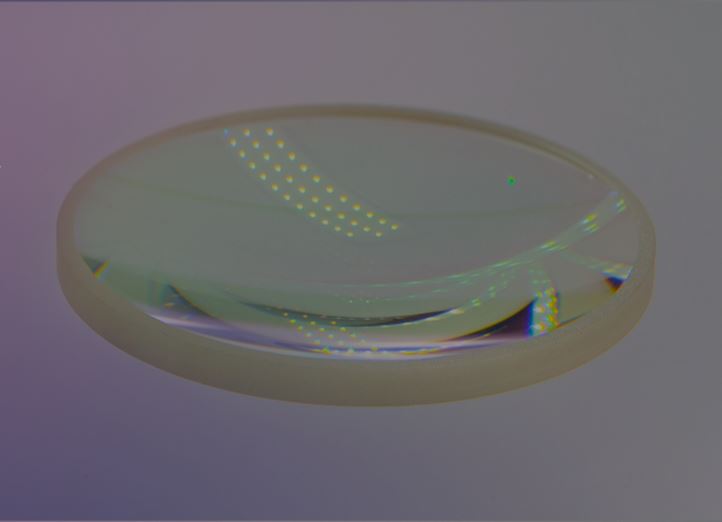

Chroma Technology specializes in the design and manufacture of optical filters and coatings for applications that require extreme precision in color separation, optical quality, and signal purity. Chroma Technology’s portfolio comprises single bandpass and single edge filters, multi bandpass and multi band dichroic beamsplitters, complete filter sets for single band, longpass, shortpass and multi band as well as filter accessories.

Laser optics must be designed and made differently from standard widefield filters and mirrors. While it is true that most laser optics will work fine in widefield applications, the inverse is clearly not true, as shown by the different specifications in each case. The differences in design and construction may not be apparent to the end-user in every laser application. However, these differences will be painfully obvious in most experiments if these specifications are not met, especially with more demanding applications such as TIRF, Raman, and multi-photon microscopy.

While the entire beam path should be considered carefully, the downloadable “application note filters and mirrors for laser applications” emphasizes the filters and dichroic mirrors used in the beam path. Get in touch with the AMS Technologies optical filter experts today to find out which Chroma Technology optical and mirrors for laser applications can meet the demands and challenges of your project.

Key Features:

- Extremely Durable

- High-throughput Sputter-coated Filters

- Very Broad Range of Filters for the Multitude of Fluorochromes Used in Epi-fluorescence Microscopy

- Dichroic Beamsplitters With Various Spectral Profiles Available

- Customized Filter Sets Available on Request

- Transmission Level: up to 97%

Applications: Fluorescence Applications; TIRF (Total Internal Reflection Fluorescence); Raman Spectroscopy; Multi-photon Microscopy