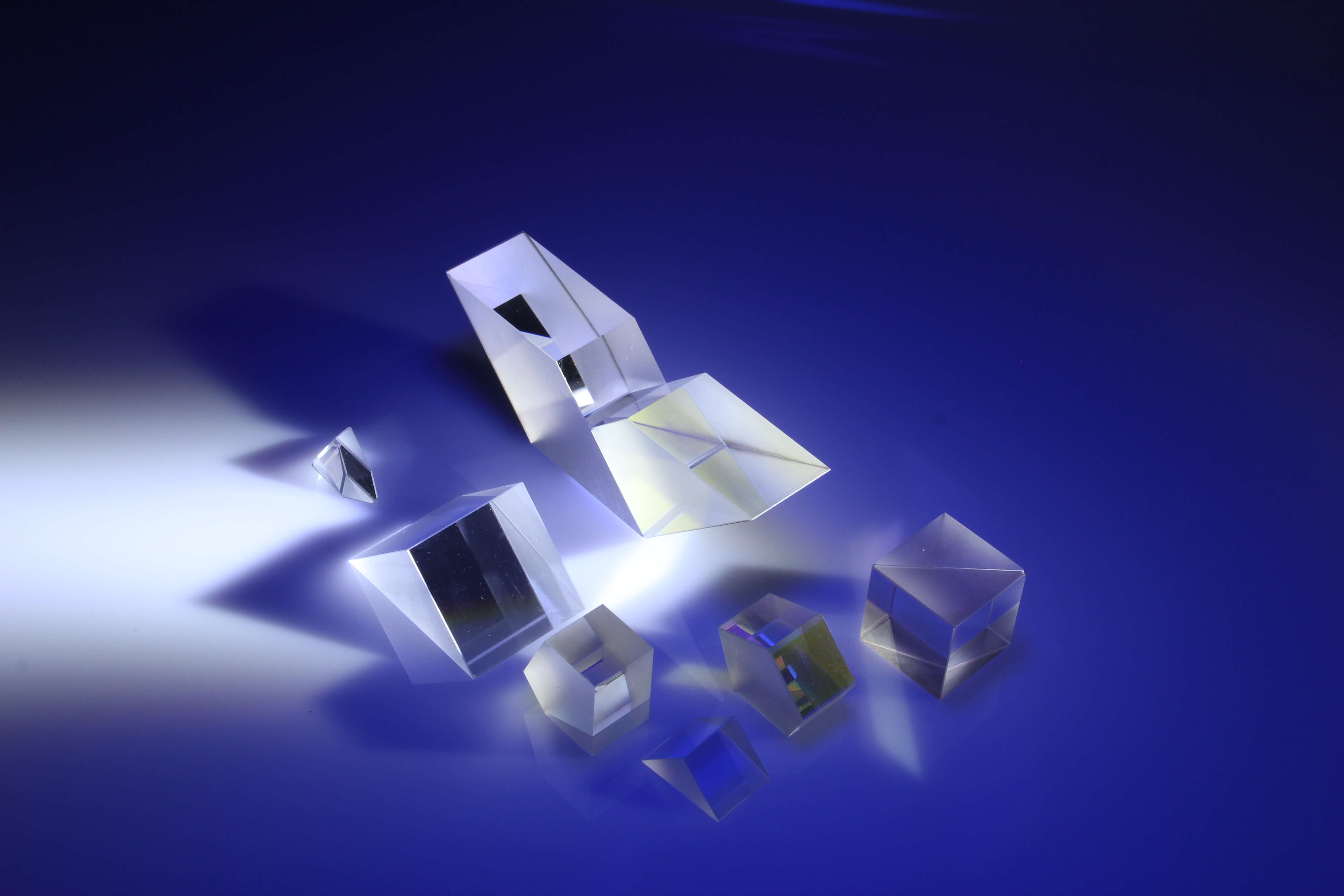

Product information "Custom Optical Prisms"

A broad range of custom optical prisms is available from OPTAplus. Within the OPTAplus product range, you can choose between various prism types like right-angle prisms, 30°-60° prisms, corner cubes, roof prisms, Dove prisms, penta prisms, dispersion prisms or wedges – with dimensions ranging from 2.00 mm to 100.00 mm.

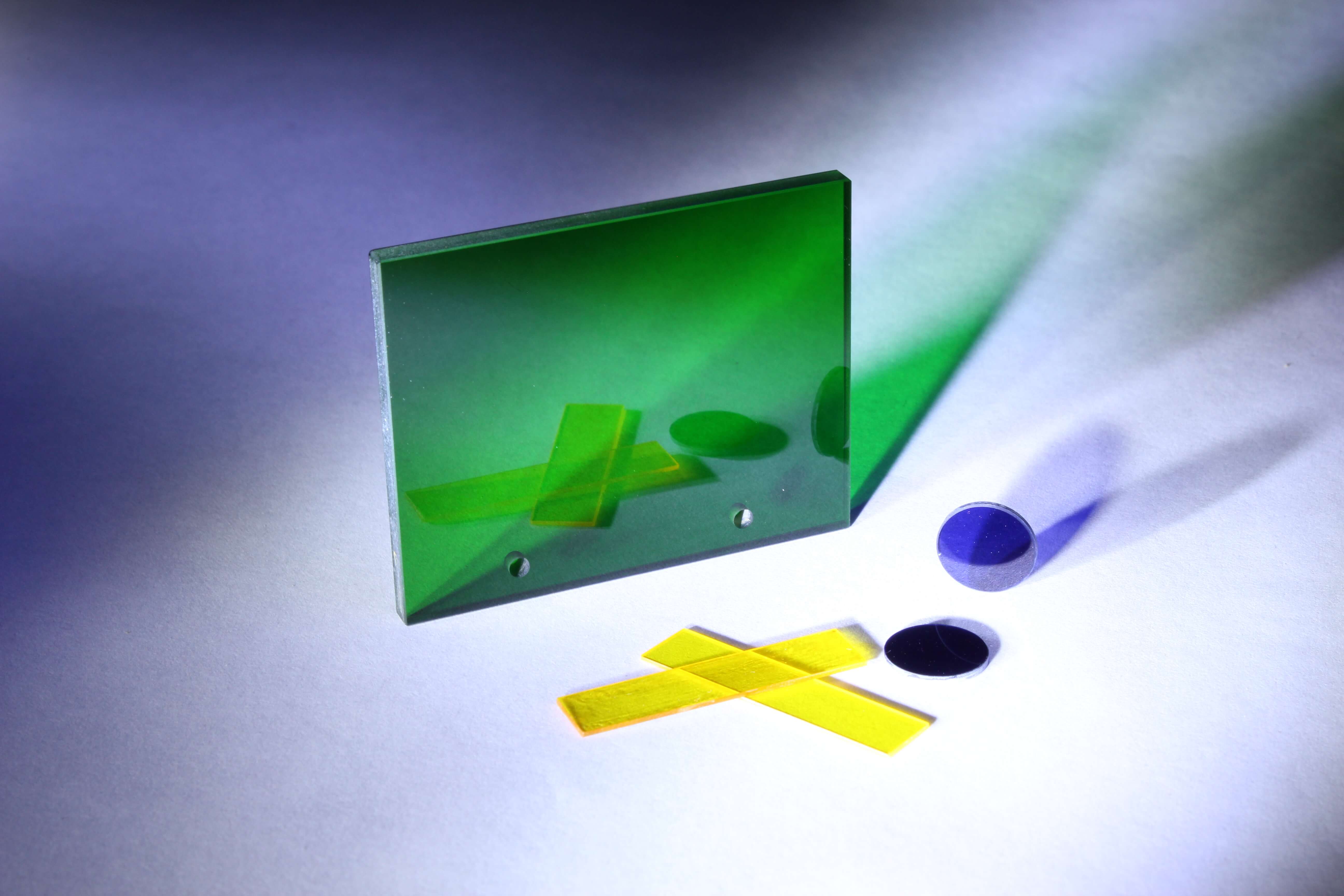

Optical prisms are made of material that is optically transparent to light of the relevant wavelength. This material is shaped into a prismatic form in which the end faces are not parallel to each other, resulting in optical refraction when a light beam is sent through the optical prism. Typical applications for optical prisms are dispersion, reflection, deflection, rotation and axis offset of a light beam.

Does your application require customized optical prisms? Get in touch with the AMS Technologies optical prism experts to discuss your specific requirements.