Peltier vs. Compressor Cooling – 8 Key Considerations To Help You Make The Right Choice

From lasers and light sources – many high-tech applications depend on accurate temperature control and efficient cooling to ensure the specified performance, reliability, and durability of critical components.

Most systems are either based on thermoelectric (also called Peltier) or compressor systems. Finding the right approach for a certain application requires balancing the strengths and limitations of the two technologies. In this article, we will briefly introduce each cooling approach and discuss eight essential considerations when deciding between Peltier or compressor-based systems.

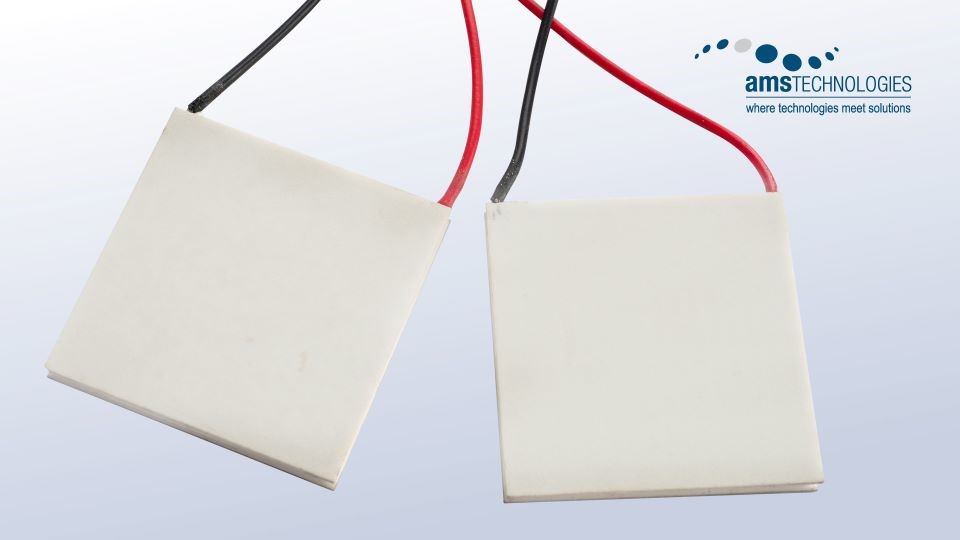

Peltier or Thermoelectric Cooling Systems

Thermoelectric cooling systems are based on the Peltier effect, a thermoelectric phenomenon that occurs at the junction of two dissimilar conductors. When an electric current flows through these junctions, a voltage difference is applied across the conductors, causing them to generate or absorb heat depending on the direction of the current. This effect causes one side of the Peltier element to absorb heat from the surroundings, while simultaneously, the other side dissipates it. This dual functionality enables quick and precise temperature control by modulating the intensity and direction of the electric current.

One of the primary advantages of thermoelectric systems is their simplicity and compactness. They have no moving parts, making them dependable and maintenance-free technology. Some typical applications are electronic cooling, cooling of laser diodes or other components such as crystals or lenses, small-scale refrigeration, and portable devices – as well as harsh operating conditions. However, thermoelectric systems only cover a limited temperature range and are not very energy efficient.

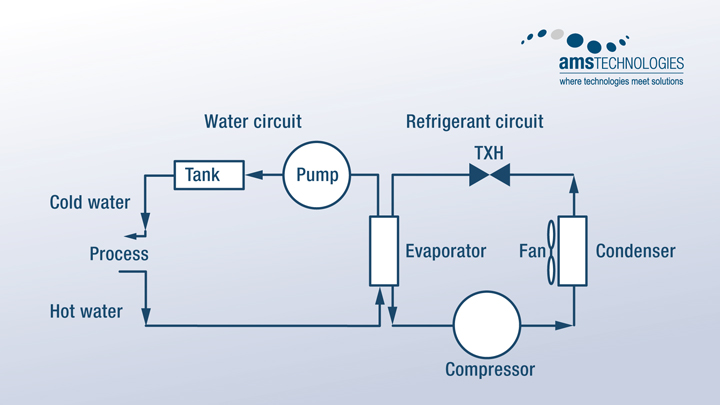

Compressor Cooling Systems

Compressor cooling systems use mechanical compression and expansion of refrigerant gases within a closed loop system. As the refrigerant gas is compressed, its temperature and pressure increase, causing it to release heat. This heat is then dissipated to the surroundings, allowing the gas to condense into a liquid state. The high-pressure liquid is then expanded through an expansion device, leading to a decrease in temperature and pressure. This cooled liquid absorbs heat from the surroundings, evaporating back into a gas.

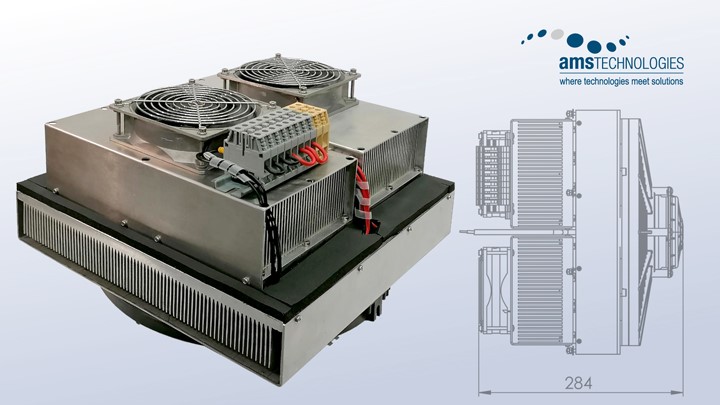

The main advantages of compressor systems are their high efficiency and ability to keep precise temperatures across a wide range. Furthermore, above capacities of 300 W, they are usually more compact and silent than thermoelectric systems. Their robust cooling capabilities make them indispensable in applications such as air conditioning, refrigeration, and industrial cooling, where large spaces and high heat loads need to be managed effectively.

Factors to Consider When Choosing Between Thermoelectric and Compressor Systems

When selecting between Peltier and compressor cooling systems, several key technical factors will influence the decision. An experienced manufacturer like AMS Technologies will listen closely to their customers and help them balance the various requirements against each other to achieve a suitable solution.

1. Temperature Range and Control

Peltier systems typically excel in lower temperature ranges (e.g., -20°C to +70°C), while compressor systems are more efficient across wider temperature ranges, including sub-zero. Additionally, compressor systems can cover a wider temperature delta than Peltier systems, making them more flexible overall.

2. Response Time

In terms of response time, Peltier systems have the edge. They do not only cool or heat very quickly, but they can also adjust the temperature in a brief time span. Compressor systems on the other hand need a bit more time to reach the desired temperature. Depending on the use case, however, a smart operating strategy can mitigate this limitation.

3. Energy Efficiency

Compressor systems typically are more energy efficient than Peltier systems – and even more so at higher cooling loads. Rising energy costs can make this a deciding factor: In some cases, the extra energy required to power a less efficient cooler can turn out to be more expensive than the higher purchase price for a more efficient system.

4. Environmental Impact

The global warming potential (GWP) of refrigerant gases only applies to compressor systems. As many synthetic refrigerants have a negative impact on global warming, legislation bans the use of such gases in several steps. However, many suppliers have already ramped up their supply of compressors running on “green” gases. Experienced manufacturers provide several options for environmentally friendly compressor coolers that meet all customer demands.

5. Size and Portability

In some applications, e.g.portable devices for the aesthetic laser market, size and weight are essential. While the Peltier elements are small and lightweight per se, the heat sinks can quickly make the systems heavy. Due to the moving parts, compressor systems require a certain minimum space, but technical progress has allowed to miniaturize compressor systems, making them suitable for more compact applications than before.

6. Noise Levels

When discussing noise levels, considerations must view the entire system as well as its operating conditions. For instance, while the Peltier elements themselves are noiseless, adding a fan for heat dissipation adds noise depending on the system load. In a similar way, compressor systems also produce more noise with increasing system load. Choosing a system with a higher cooling capacity than necessaryand operating it at partial load can minimize noise. Also, a continuous operating strategy with linear load control for compressor and fansis often perceived as less disturbing than “digital” on-and-off switching.

7. Cost

When comparing the cost, there is no fixed rule. It depends on the specific use case and system lifespan. Thermoelectric systems are often cheaper upfront and maintenance-free, as the Peltier elements have no moving parts, but may require occasional maintenance due to component degradation. Compressor systems are typically a bit more expensive initially and may need maintenance due to the moving parts, but offer lower energy costs over time, whereas the maintenance might not come to bear during the system’s expected lifespan.

8. Resilience

Thermoelectric systems have two unique advantages over compressors: They are very resilient against harsh operating conditions, and they can operate independently from their orientation. This makes Peltier-based systems an ideal choice for demanding applications, such as transportation.

Conclusion

In conclusion, the choice between Peltier and compressor cooling systems depends on several factors, including temperature requirements, energy efficiency, size constraints, and application-specific needs.

AMS Technologies carries a wide selection of both technologies for a large variety of applications:

AMS Solutions for Thermal Management

For an informed decision, we at AMS Technologies carefully evaluate the requirements of our customers to either find a suitable standard system or design and build a custom solution that exactly matches your needs.