Downloads

- T-Gauge HXC50yn Online Sensor Head for Terahertz Gauging and Imaging Luna Datasheet.pdf

- T-Ray 5000 LSG500n Line Scan Gauge for Terahertz Gauging and Imaging Luna Datasheet.pdf

- T-Ray 5000 SPG500n Single Point Gauge for Terahertz Gauging and Imaging Luna Datasheet.pdf

- T-Gauge HXP51y2 Online EPG Sensor Head for Terahertz Gauging and Imaging Luna Datasheet.pdf

- T-Gauge HSC50yn Compact Industrial Sensor for Terahertz Gauging and Imaging Luna Datasheet.pdf

- T-Gauge HXC51yn Online Sensor Head with VRS for Terahertz Gauging and Imaging Luna Datasheet.pdf

- T-Gauge SCS500n Online Sensor Solution CID1 for Terahertz Gauging and Imaging Luna Datasheet.pdf

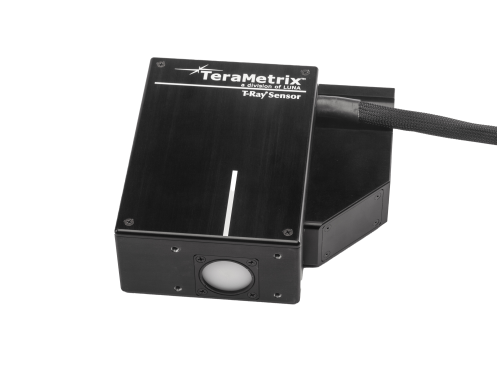

Product information "T-Gauge® Sensors & Gauges for Terahertz Gauging & Imaging"

Horizontal PER <20:1; Beam Diameter 20, 38, 40 mm; Lens 25,75,150 mm, Collimating; Min. Layer Thickness 10-50 µm; Single High-flex Umbilical

Luna’s T-Ray® 5000 measurement system is one of the fastest terahertz systems available on the market. Luna’s broad range of T-Gauge® sensor heads and gauges are paired with the T-Ray® 5000 Intelligent Terahertz Control Unit to create a complete system.

Transmitter and receiver are securely mounted inside the online sensor head’s sealed metal housing. The umbilical for the transceiver, containing the electrical and optical connections, is constructed with high flex rated electrical cable to allow for continuous scanning. When connected to a T-Ray® 5000 Control Unit, the online sensor heads will provide excellent waveform response, capable of providing detailed reflection measurement of layered surfaces or products.

The T-Gauge® HXC50yn is a high-performance online sensor head with full transceiver functionality and takes the robustness of the T-Ray® 5000 terahertz system to a new level with the ability to operate in industrial environments. Reflection measurement of thickness, multi-layer thickness, and basis weight are easily acquired. A variety of lenses are available to adjust the measurement spot size and working distance.

The “y” and “n” in the model number correspond to the focal length of the lens, and the type of terahertz transmitter, respectively – “y” = 4 for 75 mm lens and 5 for 150mm lens, “n” = 1 for a type 1 transmitter and 2 for a type 2 transmitter.

The T-Gauge® HXC51yn online sensor head adds functionality to the standard online sensor head with a virtual reference surface (VRS). Reflection measurement of thickness, multi-layer thickness, basis weight, and density are easily acquired. The VRS enables non-contact, calibration-less caliper thickness measurement as well as basis weight and density without reducing the open separation between the sensor and the product.

The T-Gauge® HXP51y2 online EPG sensor head allows measurement of thinner layers than the standard HXC50yn online sensor head. With higher bandwidth and higher signal to noise, the EPG opens new applications to terahertz process control. Coatings on metal or composite substrates and free standing films can be measured down to 10 µm (0.5 mil).

The T-Gauge® HSC50yn compact industrial sensor is designed for industrial applications that require a smaller footprint, a lighter weight or two output beams. These capabilities are met by the HSC50yn, which capitalizes on the new single fiber lighter weight umbilical, and a more compact design, to allow robot mounting. With proper attention to the configuration, it can be used to inspect two points on the same object. In the case of small diameter tubing, this can even be used to measure four orthogonal points at the same time.

The T-Gauge® SCS500n explosion-proof thickness measurement system takes the robustness of the T-Ray® 5000 to a new level with the ability to operate in flammable atmospheres, such as paint booths or coating facilities. Designed to be robot mountable and intrinsically safe, the T-Gauge® SCS500n Online Sensor Solution CID1 SCS500n is optimized for use in spray booth applications but can be used in other applications as well. The working distance of the sensor head is fixed at 115 mm, but other working distances may be available upon request.

The T-Ray® 5000 LSG500n line scan gauge (LSG) provides a handheld solution for high-speed scanning of a line 50 mm or 75mm in length. The line scan image is displayed on the screen of the handheld tool and can be analyzed by dedicated software for specific applications. Current software solutions can provide layer thickness measurements, detection of voids, or alignment of body panels with measurement of the vertical and horizontal offset between them.

The T-Ray® 5000 SPG500n single point thickness measurement gauge allows direct measurement of multiple layer objects with the press of a button. The modular nature of the measurement tool allows either straight-on or right-angle measurement tips. By using pulse time-of-flight (ToF) to make its measurements, the SPG500n has greater insensitivity to environmental and material variations that can lead to calibration inaccuracies, as well as operator inconsistencies. The measurement is fundamentally non-contact, but for hand-held use, a measurement tip is used to aid the user in positioning the object at the focus of the THz beam.

Key Features:

- Full Transceiver Functionality, No Need for Separate Transmitter and Receiver

- Collinear Design

- Two Measurement Ports With Potential to Use Both Ports at Once (HSC50yn)

- Cost-effective Plastic Lens

- TPX Lens for Low Loss (HXP51y2)

- Solvent Resistant Lens (SCS500n)

- Hardened Case for Industrial Environment, Tolerant to Dirt and Dust in the Factory

- Capable of Being Cleaned

- Safe in Explosive Environments (SCS500n)

- Single High-flex Umbilical, Long Umbilical Life in Scanner or Robot

- Simple Orientation to Target

- Variety of Focal Lengths Available: 25 mm (not All Models), 75 mm, 150 mm, Collimating Lens

- Polarization Extinction Ratio (PER): >20:1, Horizontal

- Beam Diameter: 38 mm (HXC51yn), 40 mm (HXC50yn, HSC50yn), 20 mm (HXP51y2)

- Sweep Rate: ≤8/s (LSG500n)

- Pointing Lasers to Guide Tool Alignment (LSG500n)

- Gauge Direction: 0°, 90° (SPG500n)

- Min. Layer Thickness: 50 µm (LSG500n), 10 µm (HXP51y2, Single Layer),

- 25 µm (HXP51y2, Buried Layer)

- Passline Tolerance: ±2 mm (HXP51y2, 150 mm Lens)

- Inexpensive to Replace if Damaged

- Extended Lifetime

- Replace Multiple Sensors

- Supports VRS Functionality (HXC51yn)

- Compatible With Various Motion Options

- Improve Product Quality by Optimizing Production

- Increases Product Gap for Density Measurements

- Operating Temperature Range: 0°C to +50°C

- Mounting Hardware: ¼-20 Threaded Mounting Holes

- Dimensions: 250 x 150 x 150 mm (LSG500n), 128 x 66 x 178 mm (HXC50yn, HXC51yn), 128 x 66 x 178 mm (HXP51y2), 76 x 67 x 152 mm (HSC50yn), 64 x 76 x 267 mm (SPG500n)

- Weight: 1.6 kg (HXC50yn, HXP51y2), 1.8 kg (HXC51yn), 1.1 kg (HSC50yn), 1 kg (LSG500n); 2 kg (SPG500n)

Applications: Measure Layer Thickness; Produce Scanned Images; Industrial Process Control like Commercial Roofing, Foam Density, Adhesive Foams, Paint or Coating Thickness, Plastic Extrusion, Asphalt Shingles; Nondestructive Materials Inspection Applications like Aircraft Coatings, Packaged Goods, Radomes, Spacecraft, Pipeline Repairs, Void Detection, Subsurface Defects or Inclusions, Art Conservation; Converting Applications like Paper Coating, Multilayer Films, Tires; Terahertz Line Scan Imaging