Cold Plates

Cold Plates available from Stock

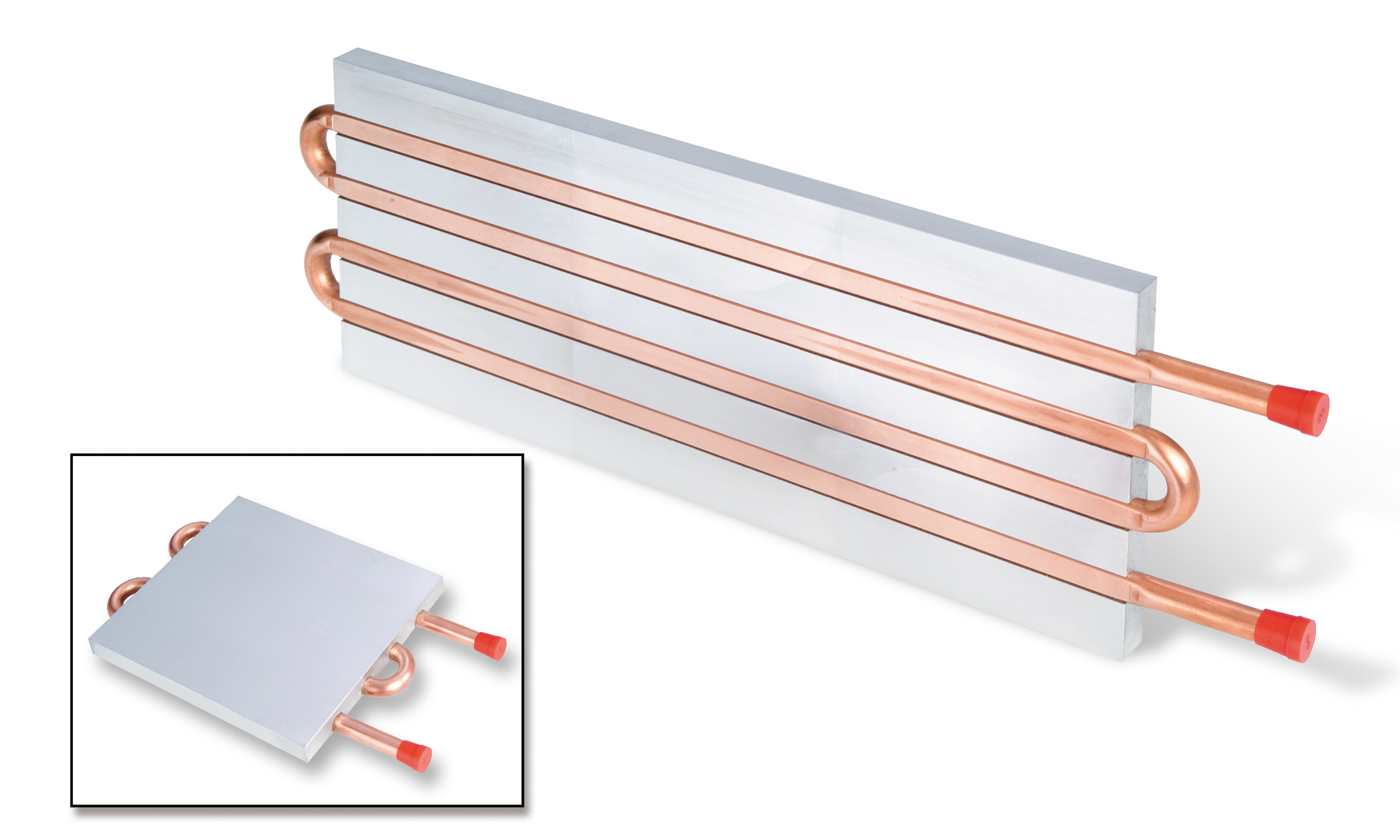

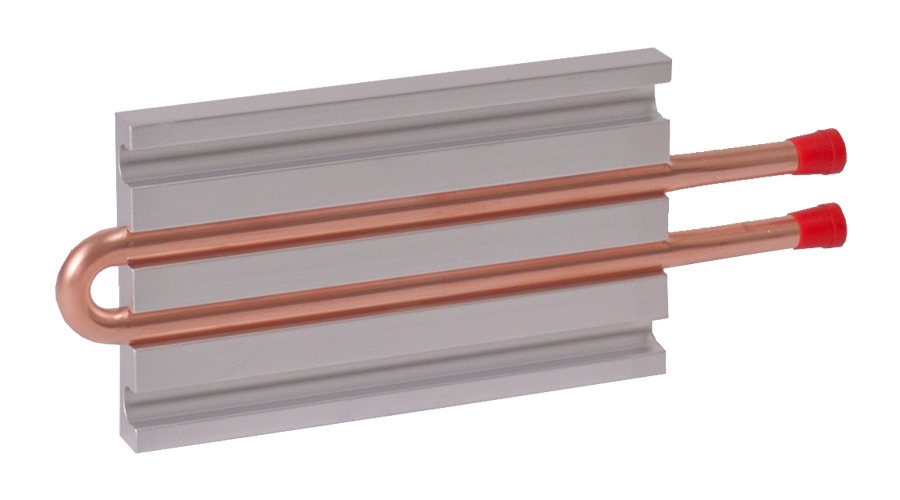

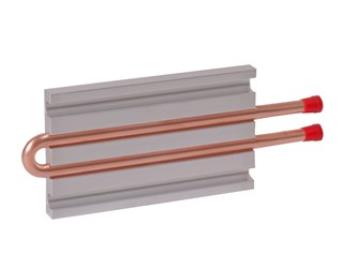

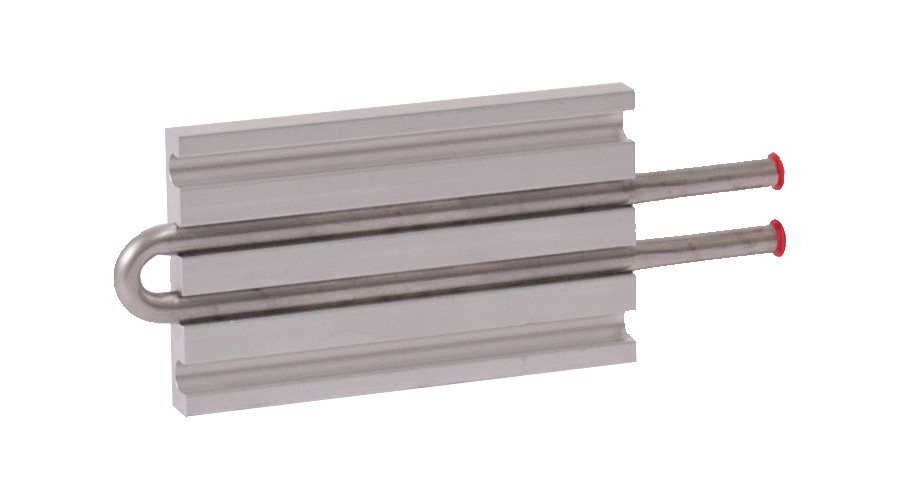

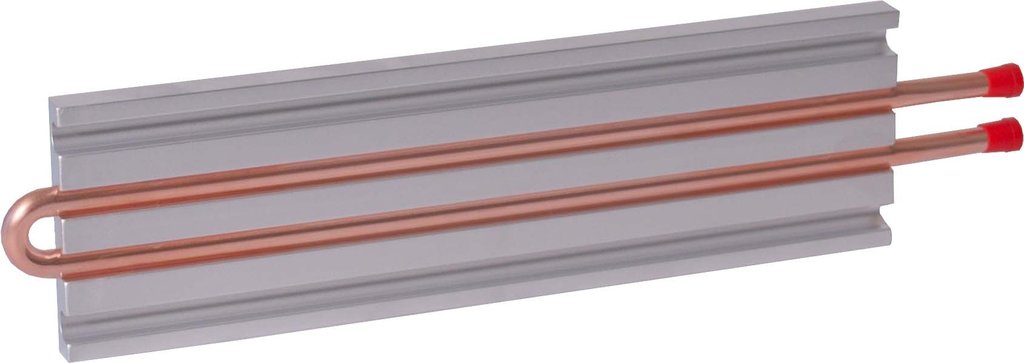

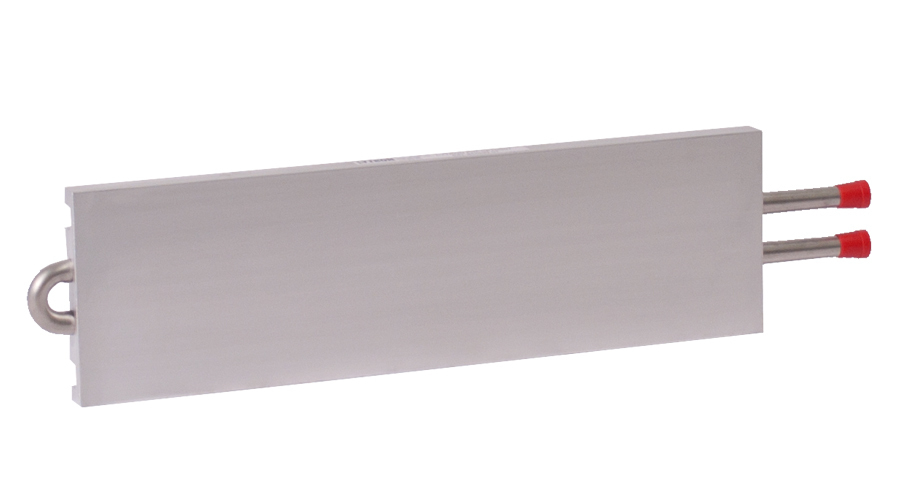

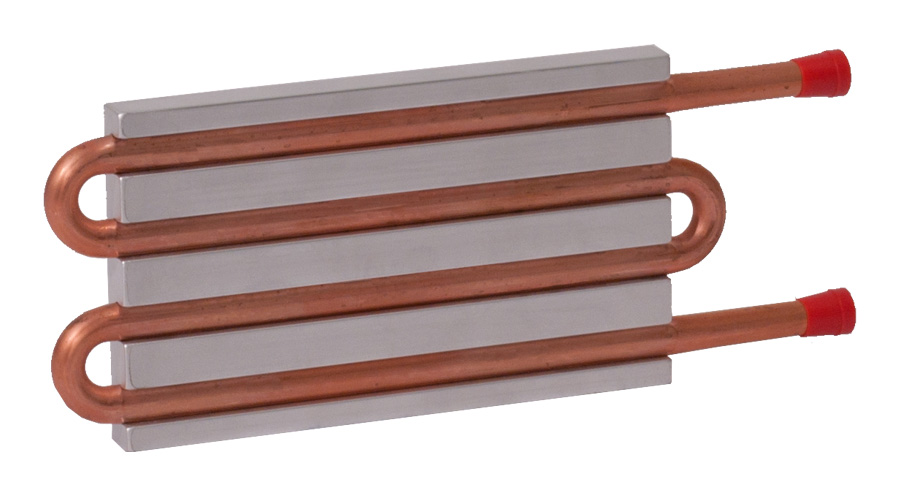

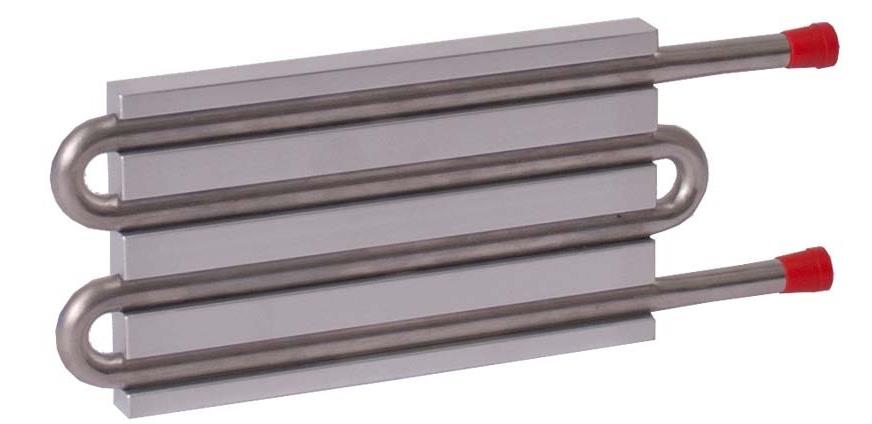

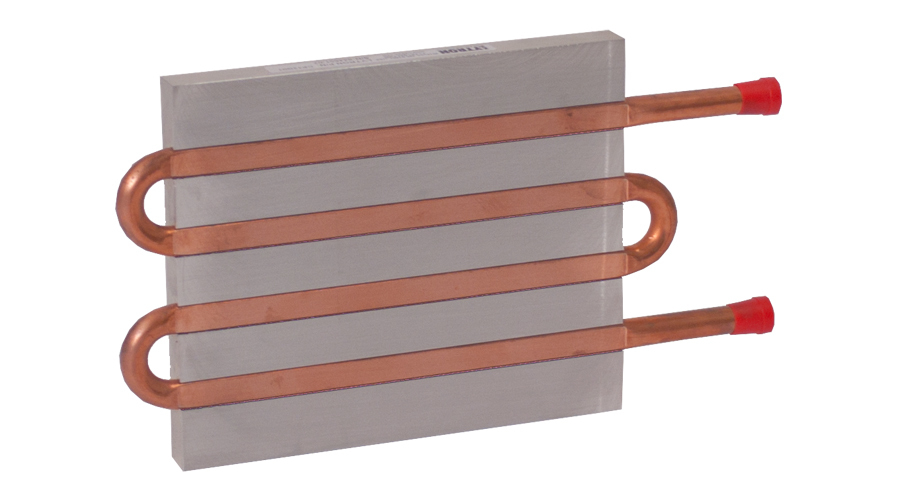

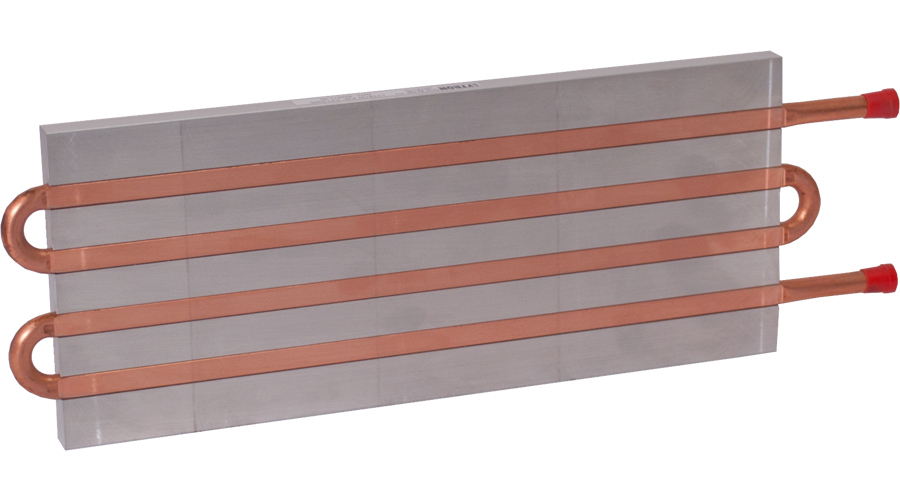

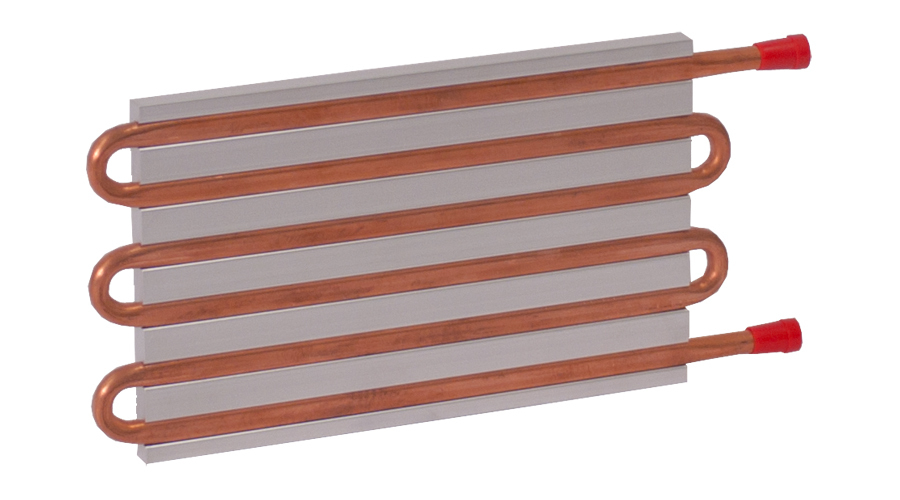

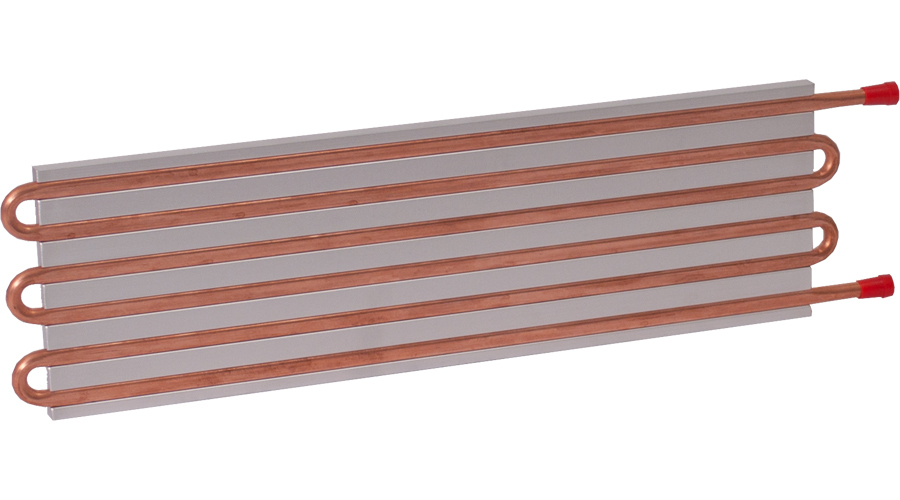

When air-cooled heat sinks cannot cope with too high power densities, liquid-cooled cold plates are the heat transfer solution of choice. AMS Technologies carries a wide variety of tubed cold plates available from stock, featuring tubes made of copper or stainless steel press-locked in a flat aluminium cold plate. 2-pass, 4-pass and 6-pass variants are available, with lengths of either 15.24 cm or 30.48 cm and widths from 8.89 cm to 12.7 cm. The tubes’ fittings are eighter straight or beaded.

We also provide very thin, compact and lightweight, U-shaped and Z-shaped flat tube cold plates with either straight or beaded fittings. These cold plates feature extremely low thermal resistance, ideal for cooling small, high watt-density components such as thermoelectric modules.

Product Portfolio

With its broad range of cold plate technologies, AMS Technologies meets the most specific fluid compatibility and performance requirements. Friction stir welded (FSW) cold plates are suitable for glycol-water and very high cooling needs, while press-lock tubed types are ideal for tap or de-ionised water.

For special applications, vacuum brazed cold plates, flat tube cold plates or pin fin types are available as well as models for low to medium power densities made of hot-rolled aluminium metal sheets.

You can’t find a standard cold plate that ideally suits your needs? Get in touch with the AMS Technologies cold plate experts for your customized cold plate solution! We can support your project throughout the entire development process of a custom cold plate, from calculation and design to manufacture and test of the resulting solution. Early involvement of our specialists in the project is the key to high-quality thermal management that meets your requirements.

Related Products

For dissipating the high heat loads collected by cold plates into the surrounding air, AMS Technologies carries a broad portfolio of fin heat exchangers.

Lower heat loads can be managed with our heat sinks, available with a wide range of high-performance heat sink profiles with optimized geometries that provide outstanding heat transfer. Using our broad range of fans for forced air cooling dramatically improves the thermal performance of both heat exchangers and heat sinks.

If you are looking for complete thermal management solutions rather than components, AMS Technologies provides an exceptional portfolio of ready-to-use liquid to air thermal management assemblies like our range of recirculating chillers, ambient cooling systems and other liquid to air thermal management solutions, using water or water-glycol mixtures for heat transfer. AMS Technologies’ liquid to liquid thermal management assemblies are ideal solutions for cooling large power electronics or energy storage systems using process water.

Definition

Today, modern devices are becoming more and more compact, with the power density growing at the same time. As a result, the requirements for contact cooling of critical heat sources are increasing considerably in many applications like lasers, optoelectronics, power electronics, medical, drives, military or aerospace and many more. Cold plates are very well suited to meet these challenges – they can be operated both on an open cooling circuit (tap or process water) and on a closed cooling circuit which, for example, uses recirculating chillers to dissipate the waste heat to the ambient air.

Fluid Compatibility is Key

When selecting your cold plate technology, it is important that the wetted surfaces of the cold plate are compatible with the coolant used. Copper as a wetted path is well suited for water and most common coolants. Aluminium, on the other hand, offers very good cooling performance in combination with ethylene glycol and water solutions (EGW) as well as oils and other liquids, but is not suitable for use with untreated water. Cold plates with stainless steel wetted surfaces are recommended for use with deionized water or other corrosive fluids.

Limited Flow Rate

In the application, the flow rate of the cold plates cannot be increased too much, otherwise erosion may occur in the liquid channels due to the excessive flow velocity of the cooling medium. Therefore, manufacturers usually specify a maximum flow rate in the specifications. For connecting the cold plate with the cooling medium there are various connection options such as open tube ends (straight or beaded), screw-on fittings, click-on quick-release fittings or threaded holes in the cold plate body.

Alternative Terms: Liquid Cooling Plate; Water Cooling Plate; Radiating Plate; Liquid to Plate Heat Exchanger; Liquid Cooled Dissipator