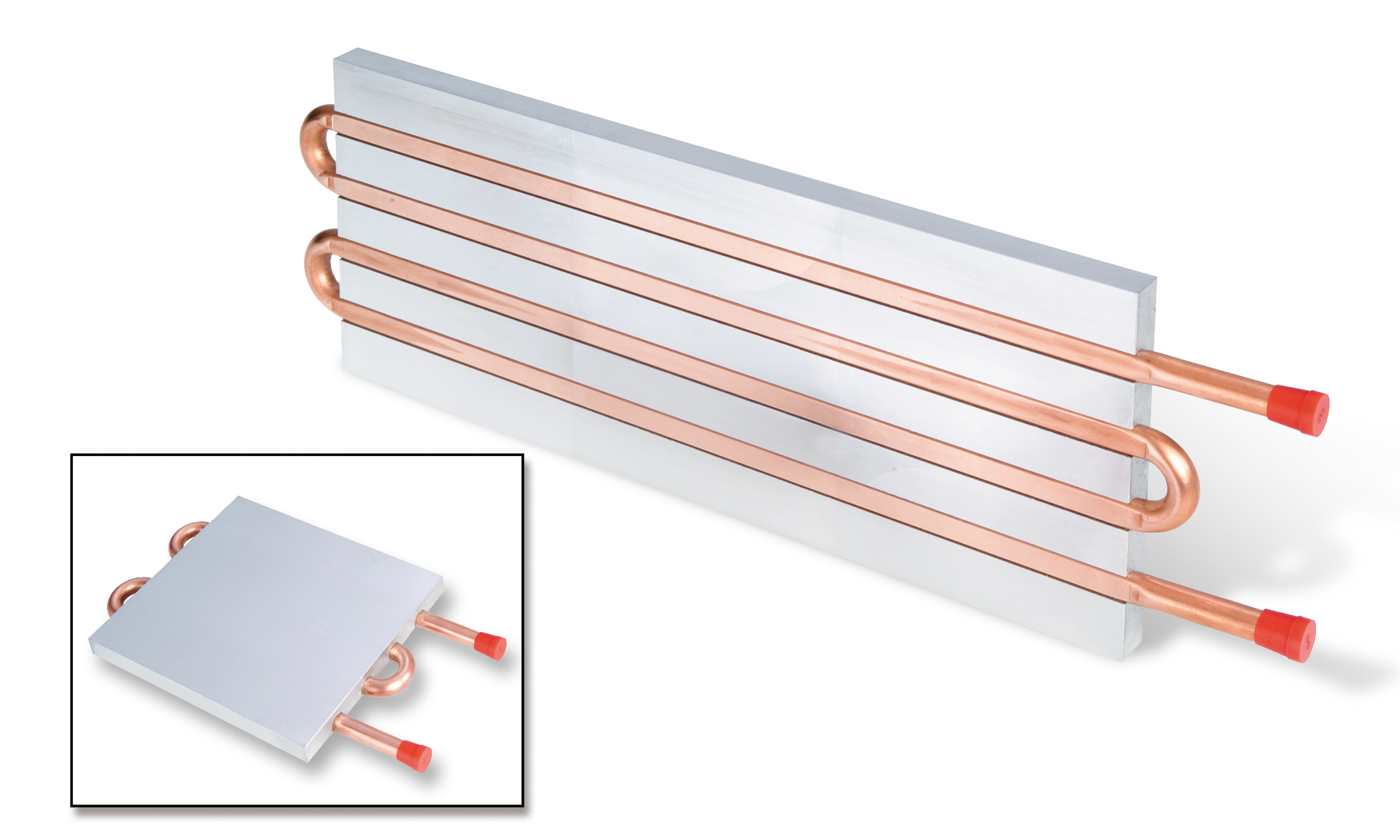

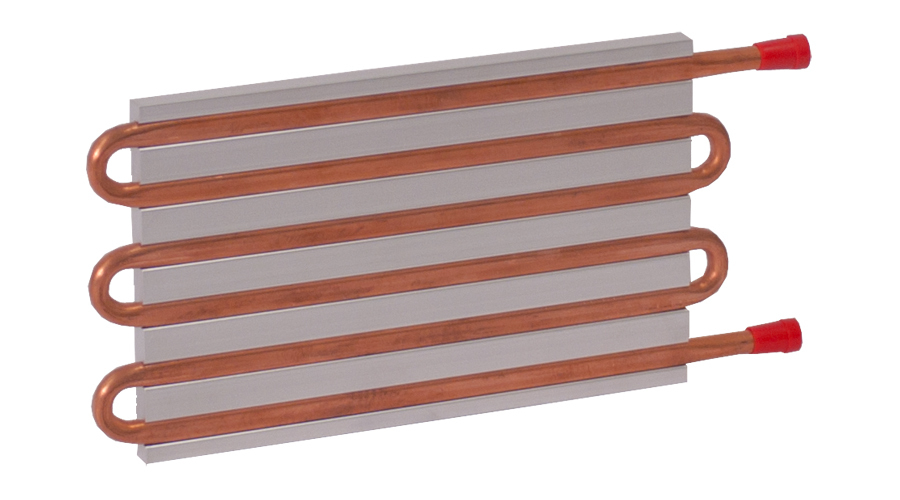

Product information "CP10G18 Aluminum Cold Plate with 4-Pass Copper tube, straight fittings"

304.8 mm X 88.9 mm, 0.008 °C/W, tubed cold plate.

The CP10™ 4-pass is a cost-effective, single-sided aluminum cold plate available with either copper or stainless steel tubes. It is ideal for component cooling applications where the heat load is low-to-moderate. Our range of standard tubed cold plates provide cost-effective thermal solutions for component cooling applications where the heat load is low-to-moderate. These tubed cold plates consist of copper or stainless steel tubes pressed into a channeled aluminum extrusion. This “Press-Lock” technology eliminates the need for performance-limiting epoxy between the tube and the plate, resulting in superior thermal performance. Each tubed cold plate has a single tube with no joint, ensuring leak-free operation.