Product number:

C008683-6

Manufacturer:

Boyd (former Lytron and Aavid)

Available stock:

2

Downloads

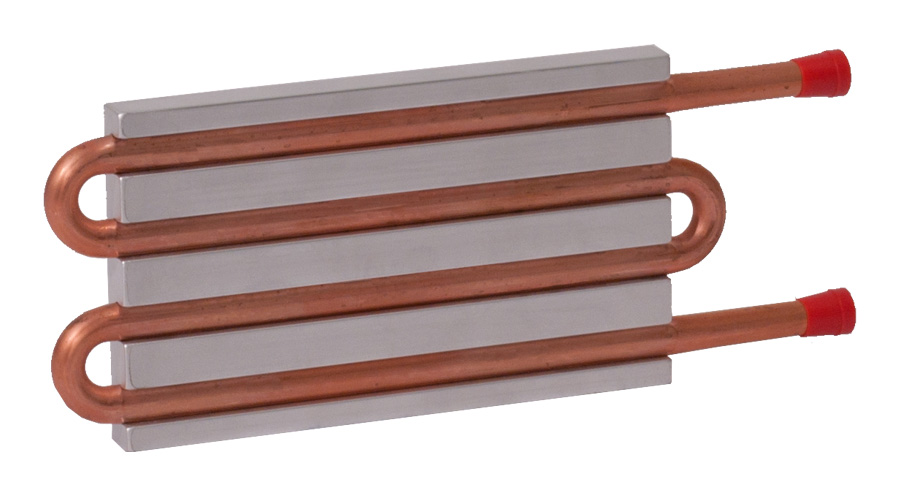

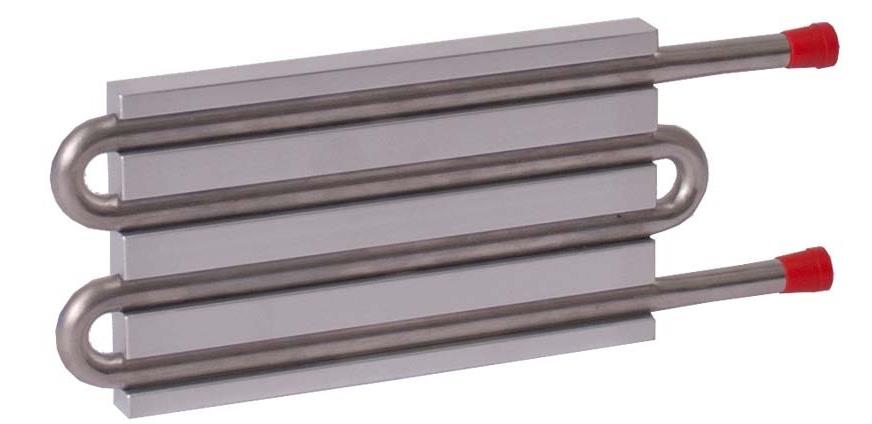

Product information "CP10G15 Aluminum Cold Plate with 4-Pass Copper tube, beaded fittings"

Aluminum Cold Plate 6"x3,5", 15.24 cm x 8.89 cm with 4-Pass 3/8" Copper tube, beaded fittings

Manufacturer "Boyd (former Lytron and Aavid)"

Boyd is the world’s leading innovator in sustainable engineered material and thermal solutions that make our customers’ products better, safer, faster, and more reliable. We develop and combine technologies to solve ambitious performance targets in our customers’ most critical applications. By implementing technologies and material science in novel ways to seal, protect, cool, and interface, Boyd has continually redefined the possible and championed customer success for over 90 years.

Boyd is also the successor of Lytron and Aavid, continuing their thermal solutions portfolio.

Related links of the manufacturer