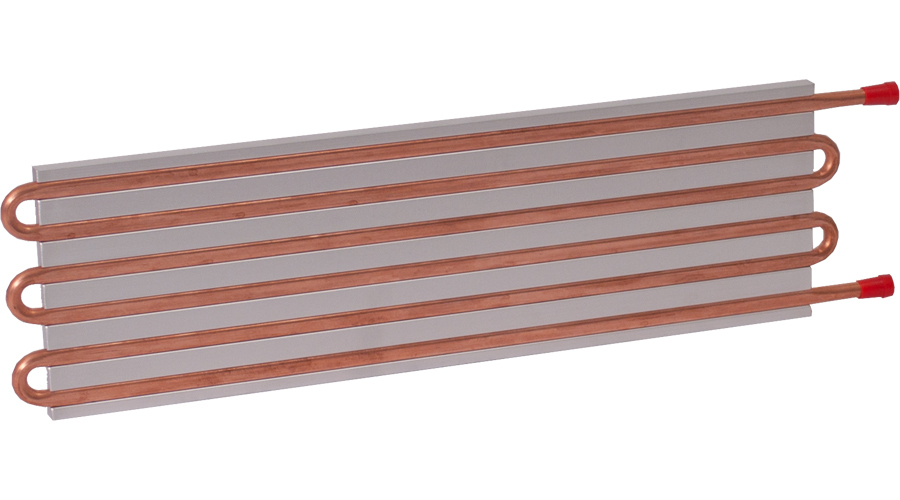

Product information "CP15G05 Aluminum Cold Plate with 6-Pass Copper tube, straight fittings"

304.8 mm x 95.3 mm, 0.004 °C/W, tubed cold plate.

Components can be mounted on both sides of CP15™, making this compact and lightweight cold plate ideal for applications where heat loads are moderating and space is at a premium. The tubes of the CP15™ cold plates are coplanar with the plate to allow for dual-sided mounting. The cold plate's tube side offers higher performance as the copper tubes are in direct contact with the component being cooled. Our range of standard tubed cold plates provide cost-effective thermal solutions for component cooling applications where the heat load is low-to-moderate. These tubed cold plates consist of copper tubes pressed into a channeled aluminum extrusion. This “Press-Lock” technology eliminates the need for performance-limiting epoxy between the tube and the plate, resulting in superior thermal performance. Each tubed cold plate has a single tube with no joint, ensuring leak-free operation.