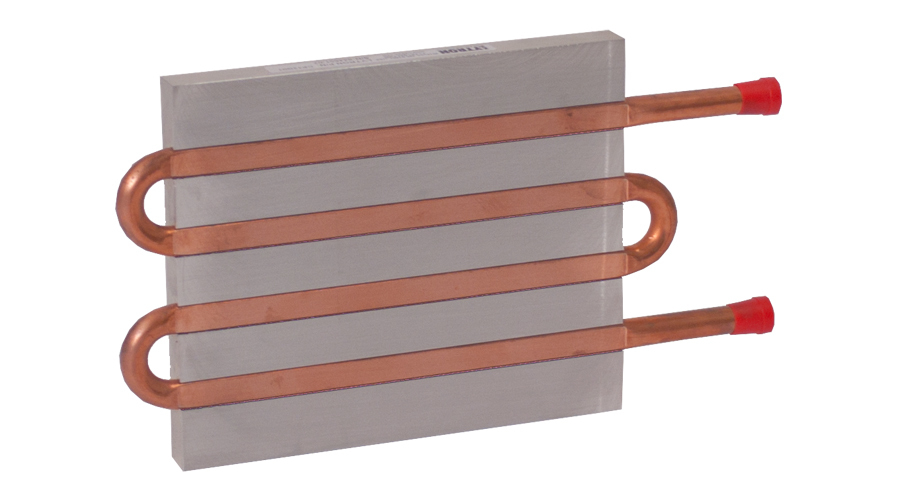

Product information "CP12G01 Aluminum Cold Plate with 4-Pass Copper tube, straight fittings"

152 mm x 127 mm, 0.009 °C/W, tubed cold plate.

The CP12™ is a dual-sided, copper tubed cold plate that offers high performance and a large mounting area. The tubes of the CP12™ cold plates are coplanar with the plate to allow for dual-sided mounting. The cold plate's tube side offers higher performance as the copper tubes are in direct contact with the component being cooled. Its epoxy-free construction results in 30% better performance than other similar sized cold plates. Our range of standard tubed cold plates provide cost-effective thermal solutions for component cooling applications where the heat load is low-to-moderate. These tubed cold plates consist of copper tubes pressed into a channeled aluminum extrusion. This “Press-Lock” technology eliminates the need for performance-limiting epoxy between the tube and the plate, resulting in superior thermal performance. Each tubed cold plate has a single tube with no joint, ensuring leak-free operation.