Product information "LOR-200 OTDRs"

400-1650 nm; Pulse Width 2-1,000 ns; Measurement Range ≤160 km; Fiber Type SM, MM; Connector Type FC, SC, ST – APC or PC

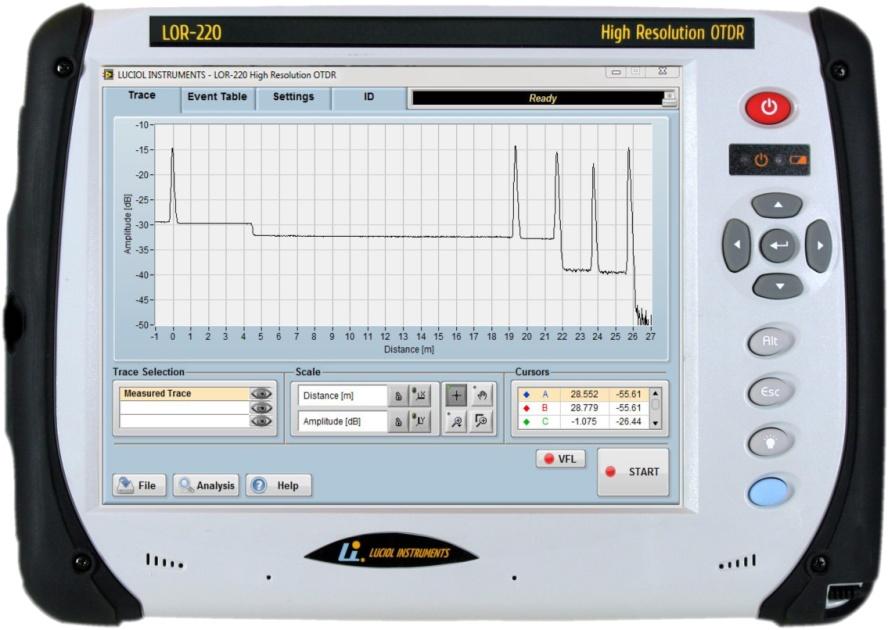

Luciol Instruments’ LOR-200 series is a family of fully portable, stand-alone high-resolution OTDRs based on Luciol’s patented scanning photon-counting technology. The instruments are integrated in a Windows-based PC platform with touchscreen interface, achieve a superior dynamic range and allow high-resolution fiber characterization up to a total distance range of 160 km.

Optimized for telecom wavelengths, typically from 1000 to 1650 nm, the LOR-200 OTDRs feature industry-leading resolution, distinguishing events with 20 cm separation, and a 50 cm attenuation dead-zone. Their unique dynamic range for short pulse lengths (up to 15 dB for 2 ns pulses) enables to see through optical splitters, even over very short distances.

The optical pulse width is variable from 2 ns to 1 µs. A large variety of wavelength options is available, up to 4 different emitters can be integrated in a single module. The fiber options include single mode (SM) and multi mode (MM) versions.

In addition, a model designed for FTTx applications is available. This version with matched filter allows in-service testing of live passive optical networks (PON), without disturbing the transmission, and can easily see through optical splitters. All necessary filter elements, including Raman-backscattering filters, are included in this OTDR.

Luciol has added several options to the LOR-200 high-resolution OTDRs:

- The Visual Fault Locator (VFL) option enables a blinking red laser, which is connected to the same connector as the OTDR itself. The user can switch from VFL to OTDR measurement directly in the software, without removing the connecting fiber. With access to the end of the fiber under test, the VFL can be used as a fiber identifier, to verify that the correct assembly is tested. This feature is especially useful for customers testing assemblies with multiple-fiber connectors with a probe. Please not that this VFL option is available only with the 670 nm OTDR wavelength.

- The Optical Power Meter (OPM) option is calibrated at 670, 850, 1310, 1550 and 1610 nm. It covers power ranges of -50 to +5 dBm at 670 to 850 nm and -60 to +5 dBm at 1310 to 1610 nm.

- With the Fiber Microscope (FM, FSL) option, the user can verify the surface quality and cleanliness of all optical connectors before use. The surface is shown onto the LOR screen. It can be saved and printed for reference or reporting. Advanced software application is also available.

With LOR-200-U, Luciol Instruments offers a table-top packaging option that requires an external PC for control and operation. LOR-200-U is equipped with a standard USB port for convenient and easy connection to most Windows based PC and is ideal for test bench integration, laboratory environment OTDR testing and many more applications.

Benefit from the LOR-200 series’ high resolution for your FTTx/PON application for precise fault location and ONT detection. If the standard models should not meet your needs, contact AMS Technologies with your requirements and together let us find the customized solution to your fiber optic measurement challenge.

Key Features:

- Lightweight Stand-alone OTDR

- Windows 10 Based Touchscreen User Interface

- Wide Range of Wavelength Options: 400 to 1650 nm

- Up to 4 Wavelengths

- Optical Pulse Width: 2 to 1,000 ns

- High Dynamic Range for Loss and Reflectance Measurements: Rayleigh Backscattering – 30 dB for 1 µs Pulse Width, 15 dB for 2 ns Pulse Width

- Distance Measurement Range: up to 160 km

- Distance Accuracy: ± (10 mm + 5 x 10-5 x Fiber Length)

- Reflectance Accuracy: ±1.5 dB

- Loss Accuracy: ±0.1dB ± 0.02 dB/dB

- Sampling Resolution: Any Multiple of 2.5 cm (250 ps)

- Single Mode and Multi Mode Versions Available

- Standard Fiber Types: Single Mode (SM, 9/125 µm), Multi Mode (MM, 50/125 or 62.5/125 µm)

- Measures Insertion Loss (IL) and Optical Return Loss (ORL) for All Types of Connectors

- Connector Type: Universal, APC or PC Type, With FC, SC or ST Adapter

- Models Optimized for PON/FTTx Applications

- Options: Visual Fault Locator (VFL), Optical Power Meter (OPM), Fiber Microscope (FM, FSL), Table-top Format (LOR-200-U)

- Remotely Controllable Through Ethernet Connection

- Operating Temperature: 0 to +40 °C

- Weight: 3.1 kg (Stand-alone Portable), 1.9 kg (Table-top)

- Dimensions: 320 x 240 x 90 mm (Stand-alone Portable), 310 x 225 x 60 mm (Table-top)

Applications: FTTx/PON; Telecom; Optical Components; Fiber Optic Sensors; Fiber Assemblies; IL/ORL Testing; Fiber Manufacturing; Aviation & Aerospace; Other