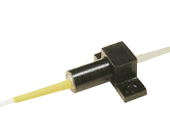

Product information "LDPC Laser Diode to Fiber Couplers"

Pigtail Style; 375 to 2050 nm; Laser Diode Power 5 to 150 mW; Coupling Efficiency 25% to 55%; Fiber Type SM, MM or PM

OZ Optics’ LDPC series of pigtail style laser diode to fiber couplers is offering optimum coupling in a small, rugged package. The couplers may be purchased prealigned, with the diode already in place, or as a kit that can be assembled by the customer using their own diode. The complete assembly procedure is quite straightforward and can be done in less than twenty minutes. A complete alignment kit, which includes tools and video instructions, is available separately.

Laser diode source couplers are available for a variety of diode case sizes, and for diode wavelengths from 375 nm to greater than 2050 nm. These source couplers work with MM, SM and PM fiber. Pigtail style laser diode to fiber couplers provide higher coupling efficiencies and lower backreflection levels than receptacle style couplers, as well as better stability. The output fiber can be terminated with different output connectors, as desired.

Laser diode to fiber couplers are available in different diameters from 0.5 inch to 1.3 inch. These tilt adjustable source couplers can be used over a temperature range of -25 °C to +60 °C and have been vibration tested. Higher temperature versions are available on request.OZ Optics also offers special, low cost, miniature pigtail style laser diode to fiber couplers for OEM applications. These packages use just a single lens to couple light from the laser diode into the fiber. They do not use OZ Optics tilt adjustment technique. This package features a compact, rugged housing, at a significantly lower cost. A variety of options like a built-in isolator, a blocking screw to attenuate the output beam as well as polarizers or polarization rotators in the middle are also available.

Key Features:

- 375nm to 2050nm

- Variety of Standard Packaging Options

- SM, MM or PM fibe

- Rugged Design

Applications: Fiber Optic Communications; Optical Alignment Systems; Process Control; Optical Sensors; Medical Apparatus; Imaging Systems ; Test and Measurement Systems; OCT Systems