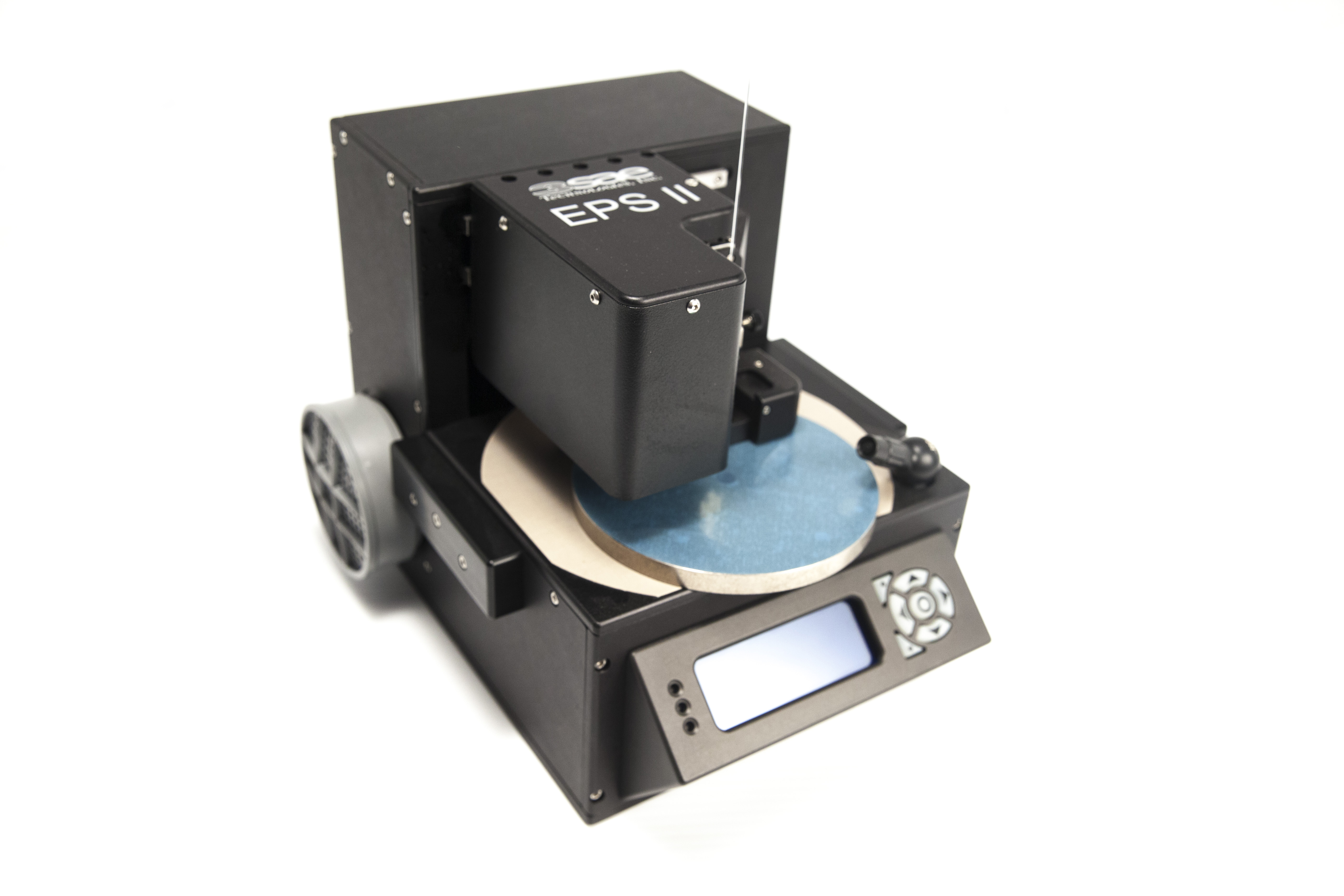

Product information "CMS Combiner Manufacturer System"

Optical Fiber Splicing/Processing System; Heat Source <300->3,000 °C; Splicing of 125-2,000 µm Dia. Fibers; Automatic Bidirectional Tapering ≤175 mm Length; Semi-automatic Cleaving of Fibers ≤500 µm Dia.

3SAE Technologies’ CMS Combiner Manufacturing System is the supplier’s latest and most advanced optical fiber splicing/processing system. The CMS is specifically designed to maintain production level repeatability for multi-kilowatt class high-power fiber combiners and other fused optical components.

The CMS system operates in partial vacuum and is utilizing the unique “Thermally Stabilized Plasma™” technology which generates an extremely repeatable and stabilized heat source with a wide dynamic range of operation from <300 °C to >3000 °C. This makes the CMS ideal for repeatable glass processing and high-volume optical component manufacturing.

The main CMS functionalities are:

SPLICING

- Splicing of 125 to 2000 µm fibers supported

- Automatic alignment with an exclusive <50 nm X and Y fiber positional resolution

- Automatic pitch and yaw alignment

- End cap splicing for cylindrical, chamfered and tapered end caps

TAPERING

- Taper lengths of up to 175 mm supported in bidirectional mode

- Automatic taper creation via intuitive software interface or manual table editing

- Exclusive "Table Based Tapering™" software included for easy user level single direction or bidirectional taper program creation and nearly infinite engineer level process control

CLEAVING

- Semi-automatic in-situ cleaving of fibers up to 500 µm

- Adjustable precision cleaving location via image feedback

Key Features:

- Extremely Repeatable Glass Processing Heat Source Ideal for High-volume Optical Component Manufacturing With a Range of Operation From <300 °C to >3000 °C

- Unsurpassed Heat Source Circumferential Thermal Uniformity for Symmetrical Ultra-low Loss Tapering and Reduced Thermally Induced Component Stress

- Contamination-free Heat Source Capable of Producing Ultra-high-strength Multi-kilowatt Class Optical Components

- Fastest Cycle Times Based on Standard Splice, Taper and Cleave Cycle Times Averaged Together

- In-situ Cleaver Included for Fiber Diameters ≤500 µm

Applications: Splicing/Processing of Optical Fibers; Repeatable Glass Processing; High-volume Optical Component Manufacturing; Maintaining Production Level Repeatability for Multi-kilowatt Class High-power Fiber Combiners and Other Fused Optical Components