Recirculating Chillers

Recirculating Chillers available from Stock

AMS Technologies offers a range of recirculating chillers available from stock that are based on thermoelectric (Peltier) technology. Optimized for cooling lasers, optics and life science applications, these high-performance thermoelectric chillers are available with cooling capacities ranging from 230 W to 460 W as well as with either aluminum or stainless steel wetted materials to match your preferred type of cold plates.

For applications where space is at a premium, AMS Technologies provides the world’s smallest air-cooled and TEC-based recirculating chiller. Delivering a cooling capacity of up to 160 W, this chiller fits easily inside your equipment or on your table top.

Product Portfolio

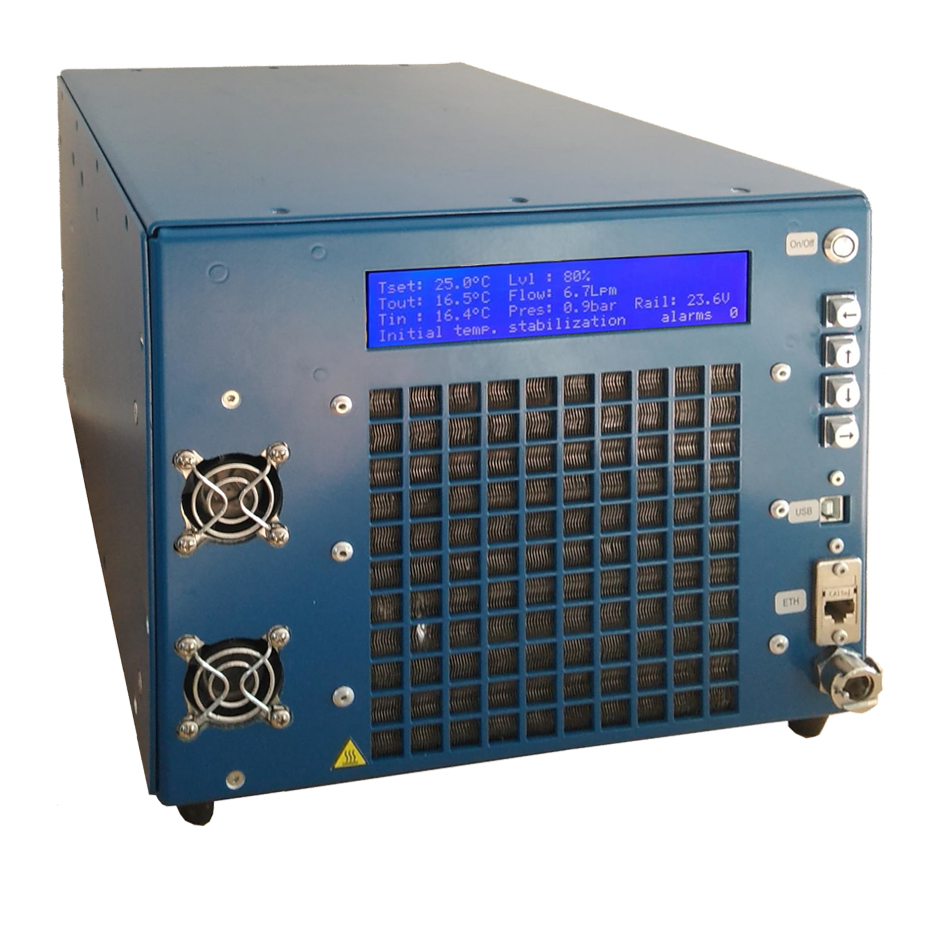

Featuring precise temperature control, quiet operation and high reliability, AMS Technologies’ portfolio of recirculating chillers ranges from compact thermoelectric chillers with a cooling capacity of 160 W to a multitude of stand-alone and rack-mount devices based on thermoelectric or compressor engines all the way to very powerful chillers capable of dealing with heat loads up to 120 kW.

AMS Technologies’ recirculating chillers are used in applications like laser cooling, laboratory instrumentation, medical and analytical equipment, scanning electron microscopes, power supplies, printers or tooling machines.

The recirculating chiller series for stand-alone use on your workbench or close to your device or machine are available based on thermoelectric or compressor technology. Cooling capacities for TEC-based systems range from 200 W to 500 W, while compressor-based stand-alone chillers are available from 400 W to 11 kW or 18 kW, but also even further as high-temperature and high-capacity systems suitable for heat loads of up to 120 kW.

The series of rack-mount recirculating chillers offer precise temperature control for sensitive equipment. Thermoelectric-based rack-mount chillers are available in heights of 4U (18 cm) and 6U (27 cm), with cooling capacities ranging from 315 W to 1000 W. Our series of compressor-based rack-mount chillers delivers cooling capacities of 200 W to 3500 W.

Beyond the standard versions, a variety of options can be provided for different fluids, pumps, low temperatures below freezing, control and monitoring, additional heating and other aspects – all the way to fully customized solutions tailored to your requirements. Get in touch with the AMS Technologies thermal management experts for your customized recirculating chiller solution! We can support your project throughout the entire development process of a custom chiller, from calculation and design to manufacture and test of the resulting solution.

One example for this is our mRC-KIT-900-TWIN, a development kit suitable for applications requiring high water cooling performance in the smallest of spaces for water coolers. Based on miniature compressors, this "mini Recirculating Chiller" development kit is a fully operational recirculating chiller that can be integrated into a customer application. It provides two independent water cooling systems in a 19-inch rackmount insert, capable of delivering a combined maximum cooling capacity of 900 W.

Properly dimensioned and inherently fault tolerant compressor circuit designs and specific controllers guarantee precise cooling in a wide range of ambient and operating conditions. Our mRC-KITs are available with cooling capacities of 450 W and 900 W. Our compressors are speed/stroke controlled over a wide capacity range, operate from voltage inverters (24 VDC or 240 VAC 50/60Hz) and utilize either R134a or environmentally friendly isobutane R600a.

Related Products

Within our broad range of accessories, spares and consumables for the use with recirculating chillers, you can find adapters for fluid handling and connecting different types of hoses, filter housings and filters for air and water, spare pumps, motors and couplings, power cords, but also consumables like bottles of high performance liquid coolant.

Our chillers are mostly used for heat transfer by recirculating liquids through liquid-cooled cold plates and dissipating the heat load to the surrounding air. AMS Technologies’ broad range of cold plate technologies, covers even the most specific fluid compatibility and performance requirements. Press-lock tubed types for use with tap or de-ionised water are available as well as friction stir welded (FSW) cold plates that are suitable for glycol-water and very high cooling needs. Vacuum brazed cold plates, flat tube cold plates or pin fin types are recommended for special applications, while cold plates made of hot-rolled aluminum metal sheets are a good fit for high-volume projects with low to medium power densities.

For lower heat loads and low energy consumption, AMS Technologies provides other liquid to air thermal management assemblies like ambient cooling systems or flush-mount liquid-based cabinet coolers. As a base for customized liquid-to-air cooling solutions, a liquid cooling development platform based on compressors is available in different performance levels up to 500 W, containing all necessary components on the refrigerant side, so the user just needs to set up the liquid cooling circuit including the pump.

Definition

Providing a highly efficient cooling system in its own housing, recirculating chillers are used in external cooling applications, dissipating heat generated in the laboratory or in an industrial process via a liquid cooling medium (usually water, often with chemical additives).

One main building block of a recirculating chiller is a liquid circuit with pump, pipes and connections as well as a liquid-to liquid heat exchanger, which is either cooled by the refrigerant of a separate vapor compression circuit (compressor-based chillers) or directly by a thermoelectric (Peltier) module (TEC-based chillers). A fan on the warm side usually ensures good heat dissipation to the surrounding air.

Compressor-based recirculating chillers also include the refrigerant circuit with compressor, condenser and thermostatic expansion valve, with the heat exchanger working as an evaporator. Due to the closed circuits in a recirculating chiller, cooling liquid and, for compressor-based types, also the refrigerant circulate without significant losses.

Recirculating chillers are usually used in continuous operation. Their active cooling techniques enable the systems to generate temperatures between -90°C and +150°C and also to cool below ambient temperature. The operation and efficiency of a recirculating chiller depend largely on variable factors such as the ambient temperature in relation to the target coolant temperature, the input coolant temperature, the type of coolant used or even the location altitude.

Alternative Terms: Recirculating Water Cooler; Liquid Cooler; Liquid Cooling System; Liquid Chiller; Lab Chiller