Optical Adhesives and Sealants

Optical Adhesives available from Stock

Our broad range of state-of-the-art adhesives (glues) is used for fast, high-precision bonding of optical components, where the adhesive is index-matched to the used components. While highly specialized, the adhesives are especially designed to meet a very wide range of applications, providing strong bonds to glass, metal, ceramics and plastics.

Packaged in syringes, bottles or bags of various sizes, our optical adhesives available from stock simplify bonding processes that require critical alignment or exact positioning. They guarantee high processing speed combined with high reliability. Curing conditions can differ, using either heat or UV light to reach the optimum adhesion.

Our broad range of one-component UV-curing optical adhesives will set in seconds when exposed to ultraviolet light and can provide excellent light transmission over a wide spectral range. These optical adhesives are designed for bonding, where low strain, optical clarity or low outgassing are required in military, aerospace, fiber optics or commercial optics. Every adhesive is index-matched, with refractive indices available in the range from 1.315 to 1.7. If you need a portfolio of adhesives for various refractive indices, kits containing bottles with the most frequently used adhesives might be your products of choice.

Two component, 100% solids, heat curing epoxy adhesives are also available from stock, designed for high-temperature applications. These adhesives will perform continuously at +200 °C while also tolerating +300 °C to +400 °C for several hours.

Product Portfolio

In addition to the optical adhesives available from stock, we support a range of epoxy- or acrylate-based adhesives for various purposes. Special glues have been developed for the use with optical waveguides, for assembling optical fiber arrays, e.g. to fix optical fibers in v-grooves, as well as high-precision variants or adhesives with either low or high refractive index.

We also carry high refractive index, UV-curable resins for nano imprint lithography, providing highly functional fine patterns with high accuracy. Our series of sealants for optical parts is suitable for applications like sealing the openings and junctions of protective casings with very low moisture permeability.

You can’t find an optical adhesive exactly covering your requirements? Together with our suppliers, AMS Technologies can provide customized adhesives, e.g. with adjusted refractive index, viscosity or transmittance, to meet each customer's needs. It is possible to respond to several further kinds of requests such as with/without solvent. Please contact the AMS Technologies optical adhesives experts to discuss your customized optical adhesive solution.

Related Products

For our state-of-the-art optical adhesives, a broad range of dispensing systems and accessories is available, covering dispensing requirements in numerous industrial applications.

After dispensing, optical adhesives must be cured by either heat or UV light. AMS Technologies carries a range of curing solutions, from remote controlled curing ovens to industrial UV LED systems for UV curing applications.

Our range of single and dual arm fume extraction systems use an internal filter system with selectable combinations of pre-filters and main filters to filter hazardous particles and gases which an external system would pump into the outside environment causing pollution.

Finally, our fiber optics polishing equipment can be used for polishing the fiber stub or end face with our broad offering of polishing films in various grit sizes.

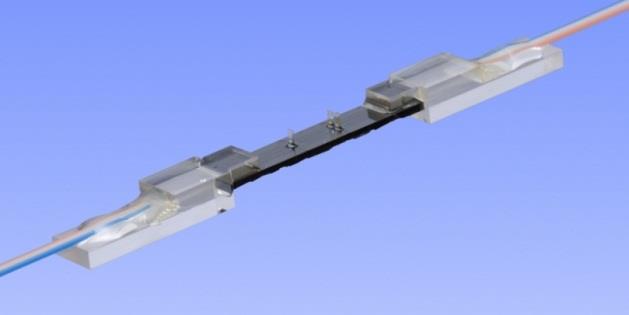

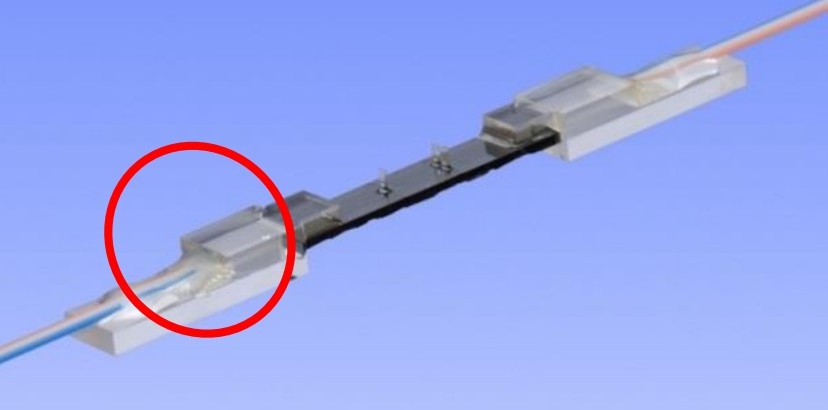

The main applications for our optical adhesives, including the associated dispensing and curing equipment, are assembling single mode (SM), multi mode (MM) or polarization maintaining (PM) optical fibers into fiber connectors for creating optical fiber patch cables, bundles and assemblies. This product portfolio is further complemented by a range of fiber connector parts and corresponding mating sleeves and adapters as well as a large array of cleaning tools.

AMS Technologies can also offer an end-to-end solution for the assembly and test of optical connectors that is exactly tailored to your requirements. In our broad portfolio you can find tools for stripping and cleaving your fibers prior to assembly and finally testing the results of assembling, polishing and cleaning your connector with microscopes, interferometers as well as handheld and automated test equipment measuring return loss.

Definition

Bonding is an essential technological process in many industries, utilizing adhesives to either fix or connect components made of various materials. Optical adhesives usually exist in liquid or paste form and are used to fix or bond together optical components of all kinds (optical fibers, optical parts such as prisms or lenses, displays, glasses, etc.).

Single- and multi-component adhesives are available, whose curing can be done by either ultraviolet light or elevated temperature. Curing by UV light usually happens in a very short time (a few seconds), which facilitates precision alignment or positioning of the optical components to be bonded.

Optically transparent adhesives are light-transmitting and are therefore suitable for use in the optical path. Optical bonding is often used to optimise the optical path at the joint, but for this the transmittance and the refractive index of the adhesive used must be matched to the components to be bonded.

Optically opaque adhesives are used when no light is to be transmitted through the adhesive – for example for bonding a mirror to a suitable holder. This type of adhesive is usually based on two components and does not require UV light for curing.

How to Select the Right Optical Adhesive

Each type of optical adhesive has strengths and limitations, so selecting the most suitable adhesive for the job can be a challenge. The material properties of the adhesive required for the application must be weighed against the requirements of the manufacturing process. If the adhesive is applied in the optical path, light transmission and, where appropriate, refractive index are considerations, but there are also a number of other aspects to take into account.

Depending on whether the adhesive itself is to form an optical path or fill an optical gap, guide light into the gap or bridge the gap, a suitable viscosity of the adhesive must be chosen.

For some applications, such as the assembly of fiber optic connections or connectors, the hardness and elasticity of the cured adhesive material are important because the fiber connection usually needs to be ground or polished afterwards and should prevent movement of the fiber, even under mechanically demanding conditions.

All adhesives shrink in volume to some degree during the curing process, which can lead to mechanical stress in the components and affect their positioning or alignment. While standard epoxy adhesives usually show a shrinkage in the magnitude of low single percent digits, special UV-curable adhesives reduce the volume by far below 1% while maintaining optical transparency.

The outgassing of adhesive material or solvents during application as well as during or even after curing can also play a role, not only because of possibly harmful processes for the optical components but also because the gases can be relevant to health. During processing, fume extraction systems can provide a solution.

Alternative Terms: Optical Glue; Optical Bond; Optical Bonding; Optical Resin; Optical Assembly Adhesive; Optical Filler