Product information "Nano Imprint Lithography Resins"

Refractive Index 1.689-1.9; Viscosity 15, 138 mPas; Transmittance 94%-97%; UV Curing Conditions 100 mW/cm², 1, 5 min; Tg +100, +125 °C

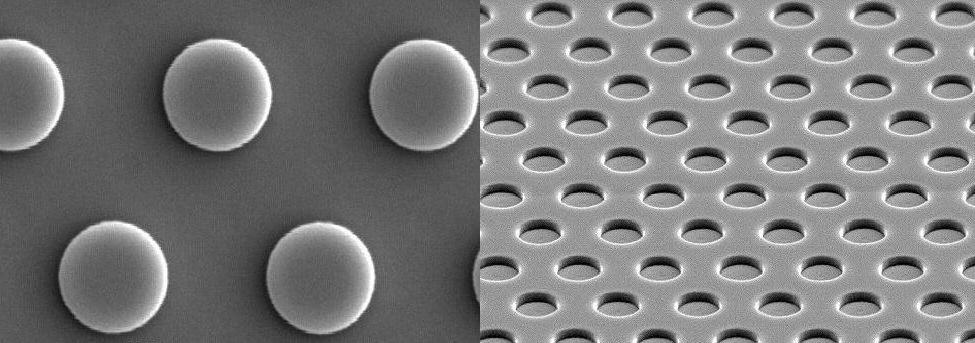

Nano imprint lithography is the next generation process technology. This simple and low-cost fabrication technology enables nano-scale patterns. NTT-AT’s high refractive index, UV-curable nano imprint lithography resins provide highly functional fine patterns with high accuracy.

This series’ high refractive index (RI) helps to miniaturize optical components. Resin type #18210 features a refractive index of more than 1.7 and contains solvent, good for creating a thin film (<1 µm). Solvent-free resin type #18247 enables to produce thicker layers (>2 to 3 µm) and can create nano-size patterns without a pre-baking process to evaporate the solvent. This product maintains a high refractive index of 1.689 to 1.765, depending on the light’s wavelength, keeping a high transparency in the visible wavelength range by using non-organic fillers.

With the recent increase in the refractive index of glass for AR/VR, aimed at expanding the field of view, the demand for resins to match this higher RI is also increasing. Just recently, NTT-AT has developed new 1.8 and 1.9 refractive index resins with high transparency and good nanoimprintability, able to fabricate a uniform thin film by spin coating. These resins are expected to contribute to the improvement of the flexibility in optical design.

NTT-AT uses high-precision refractive index control technology in the manufacture of optical adhesives to increase the concentration of high-refractive-index inorganic nanofillers and achieve high refractive index while optimizing the resin formulation. These resins are compatible with high-refractive index glasses and can create nano-patterns with a line width of 50 nm to 10 µm by nanoimprinting. They feature high light transmission in the wavelength range from 400 nm to 800 nm.

If you are looking for high refractive index resins for nano imprint lithography, please contact the AMS Technologies optical adhesives experts to find out more about our range of solutions.

Key Features:

- High Accuracy

- High Refractive Index (RI): 1.689 to 1.9

- Characteristics of Resin can be Customized

- Solvent-free Variant (#18247) Enables Omitting a Pre-baking Process as well as Dispensing and Pushing Mold and Substrate Together

- Solvent-free Variant (#18247): No Solvent Affecting the Substrate, Even Possible to Create a Bulk Film Without Substrate

- Solvent-free Variant (#18247) Not Categorized in Dangerous Goods, Thus Easy to Transport

- High Light Transmittance: 94% to 97%

- Viscosity: 15, 138 mPas

- Abbe’s Number: 24, 31

- Haze: <0.1%

- Shrinkage: 6%, 7%

- UV Curing Conditions: 100 mW/cm², 1, 5 min

- Glass Transition Temperature Tg: +100, +125 °C

Applications: High Refractive Index Nanoimprinting; Coating; Solvent-free Nanoimprinting