TEC Temperature Controllers

TEC Temperature Controllers available from Stock

AMS Technologies‘ broad portfolio of TEC temperature controllers or TEC drivers available from stock is very well suited for drive and control of thermoelectric modules/coolers (TEC) based on Peltier technology. Analog and digital TEC drivers with PI (proportional, integral) or PID (proportional, integral, derivative) type of control are available.

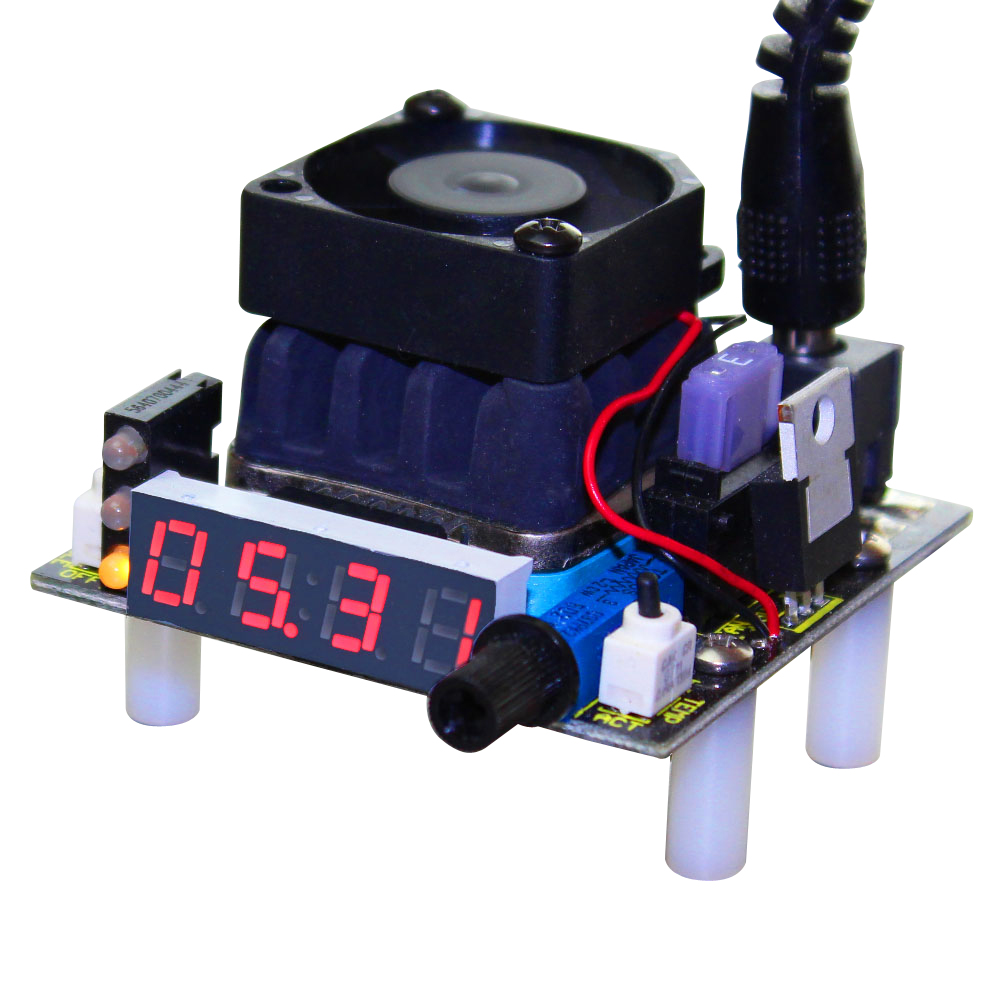

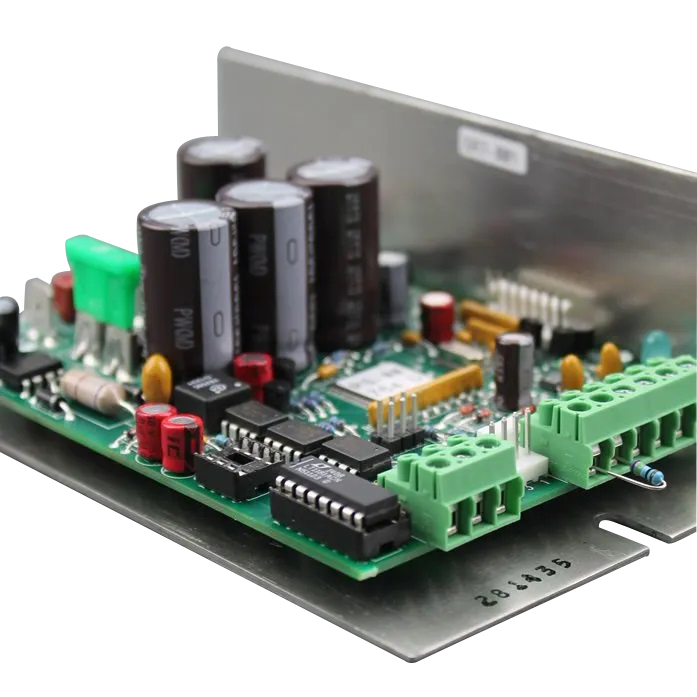

Our comprehensive inventory of TEC temperature controllers and drivers comprises systems for PCB, chassis or benchtop mount, providing TEC drive currents ranging from 1.5 A all the way to an impressive 28 A. In combination with thermistor or RTD temperature sensors, these devices are able to control the temperature of laser diodes or power electronics very precisely – some models can even provide temperature regulation down to <0.001°C.

Our product range offers cost effective and reliable temperature control solutions for your projects, capable of being implemented into an array of pre-existing systems and applicable in wide spectrum of industries.

Some of our temperature controllers can also drive heating elements based on resistive technologies. If you can’t find an off-the-shelf TEC temperature controller that meets your needs, please contact the AMS Technologies temperature controller experts – together with our suppliers we can create a temperature control solution tailored to your requirements. We guarantee that we can provide a solution to any thermal management issue, no matter how complex.

Related Products

Use our temperature controllers to drive and control AMS Technologies’ broad range of thermoelectric or Peltier modules that comprises variants for industrial applications or consumer devices, multistage modules for high temperature difference requirements as well as small TECs, ideal for assembly into various sockets, packages & housings (e.g. TO-Cans, Butterfly, etc.) of optoelectronic and other electronic components. Our temperature controllers are also preferred solutions to drive TECs that are integrated in many of our laser diodes, modules and systems.

Our portfolio of accessories for TEC temperature controllers ranges from various pre-confectioned cables and dedicated thermal management components like heat sinks, thermal paste and fans all the way to power supplies, digital displays and remote control units as well as evaluation boards.

Definition

Thermoelectric coolers (TECs or Peltier elements) are particularly suitable for keeping a device or assembly precisely and constantly at a desired constant temperature. A TEC temperature controller supplies the voltage and current required by the TEC and ensures that the temperature is maintained exactly at the desired level, based on the feedback from a temperature sensor. With high-precision temperature sensors such as thermistors, RTDs or linear integrated circuits, temperature stabilities of ±0.01 °C to ±0.001 °C can be achieved. For less critical applications, thermocouples are also suitable, with which the temperature can be stabilized to about ±1 °C.

Proportional TEC Temperature Controllers

Like very basic “On-Off” models, proportional TEC temperature controllers are energy efficient. However, the proportional controller gives you better performance. This system functions from a band around the set point to avoid constantly cycling on and off. It does this by reducing percentage of power as you get closer to the set point.

Proportional, Integral, Derivative (PID) TEC Temperature Controllers

The most complex and accurate type of control, PID, is an abbreviation for Proportional, Integral and Derivative. As an enhanced version of the standard proportional control type, PID calculates the system’s hysteresis to manage the temperature and ensure maximum stability. Proportional TEC temperature control can be slow to climb back to the proper set temperature, thus the integral calculation allows the temperature controller to increase the rate of change to bring the system back to the set temperature faster. The derivative function monitors the change over a much longer period of time than the integral, which allows the system to more accurately compensate for rapid changes in temperature.

Pulse Width Modulation TEC Temperature Controllers

Pulse-width modulated controllers are more efficient and smaller than their linear-mode counterparts. Thanks to high‑efficiency switching technology, these controllers dissipate very little heat internally, and in most applications no additional heatsinking is required for safe operation. The controller drives the TEC with a pulse-width modulated current. If more current is needed to keep the thermal load at the desired temperature, the controller increases the modulation ON-time and decreases the OFF-time.

How to Select the Right TEC Temperature Controller for Your Application

To decide which TEC temperature controller is most appropriate for driving your TEC or Peltier module(s), first sort by your maximum TEC current requirement: choose from our range of TEC drivers with TEC currents from below 1 A up to 28 A. Then choose what mount option would fit best – components for PCB mount, modules for chassis or benchtop mount or instruments for benchtop or rack mount – and also if features like low profile, integrated fan or integrated heat sink are desired.

If you can’t find an off-the-shelf TEC temperature controller that meets your needs, contact the AMS Technologies temperature controller experts – together with our suppliers we can create a temperature control solution tailored to your requirements. We guarantee that we can provide a solution to any thermal management issue, no matter how complex.

Alternative Terms: Temperature Controller; TEC Driver; TEC Controller; Thermoelectric Cooler Driver; Thermoelectric Module Driver; Thermoelectric Module Controller; Peltier Module Driver; Peltier Module Controller; Resistive Heater Driver; Resistive Heater Controller