Multi Mode Fibers

Multi Mode Fibers available from Stock

Our range of multi mode (MM) optical fibers available from stock allows multiple modes of light to propagate through the fiber. They enable transmitting light of high optical power and are offered with special features like polyimide coatings for high operating temperatures, low numerical aperture or low bend sensitivity.

Product Portfolio

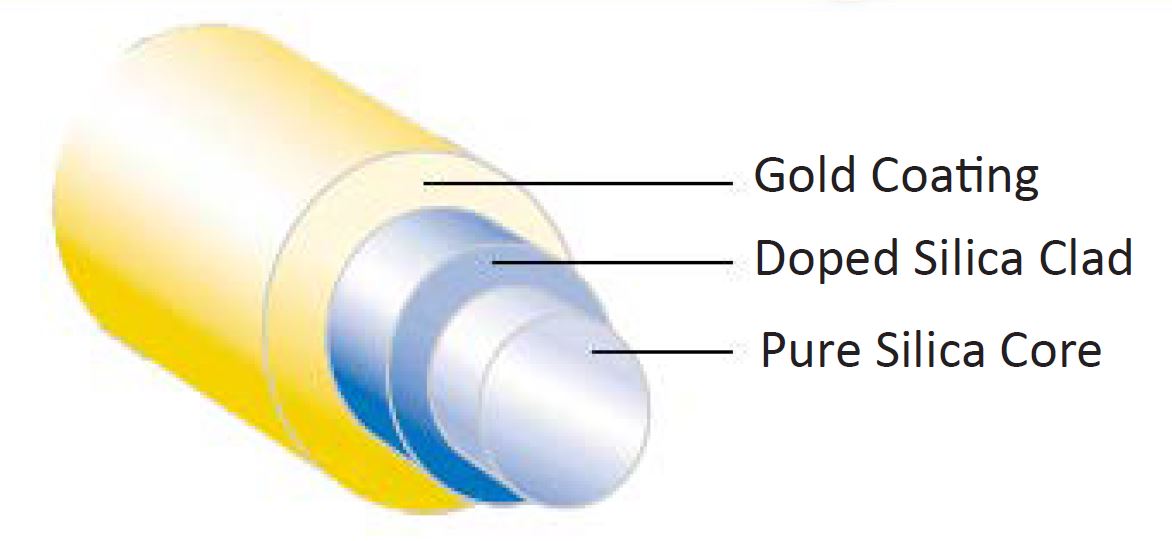

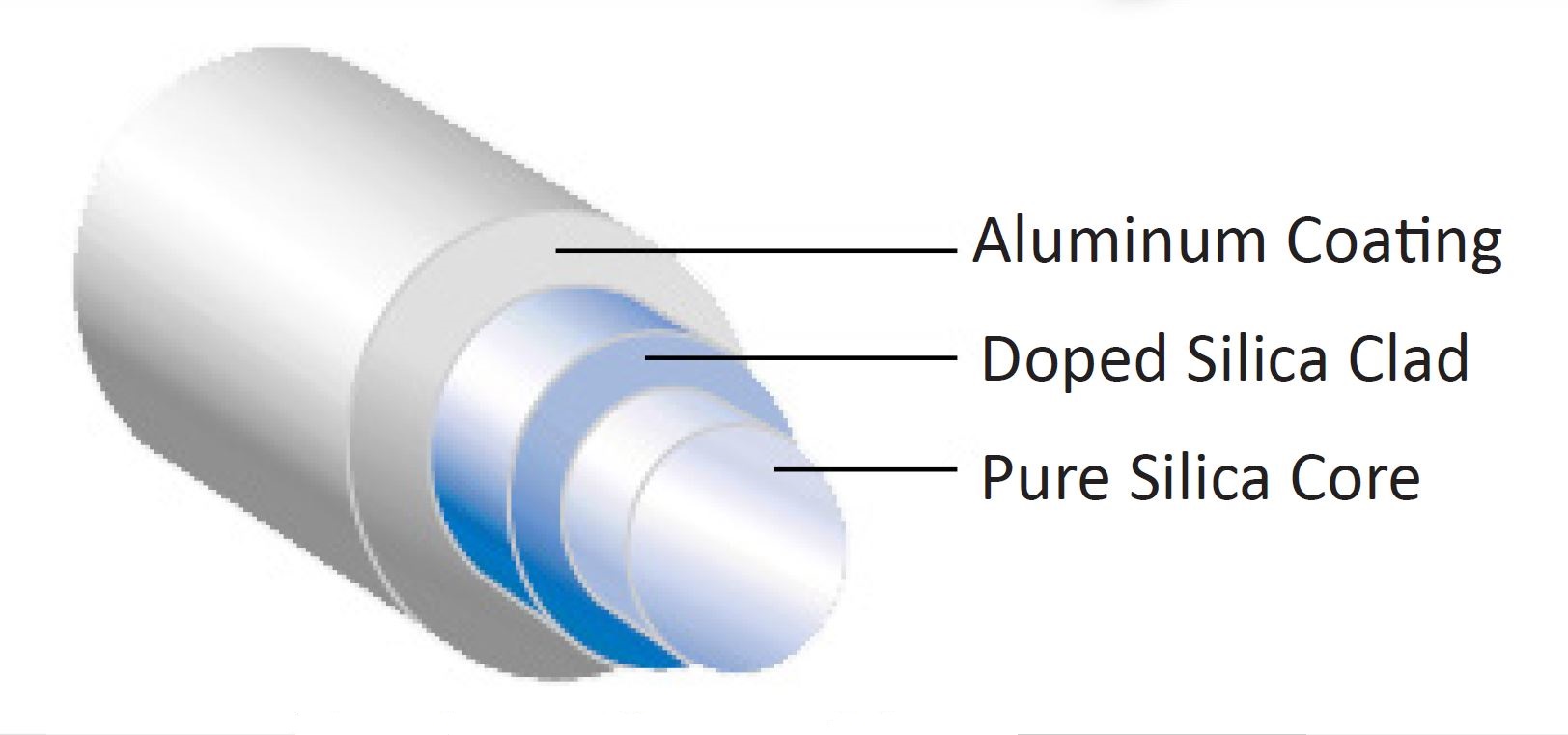

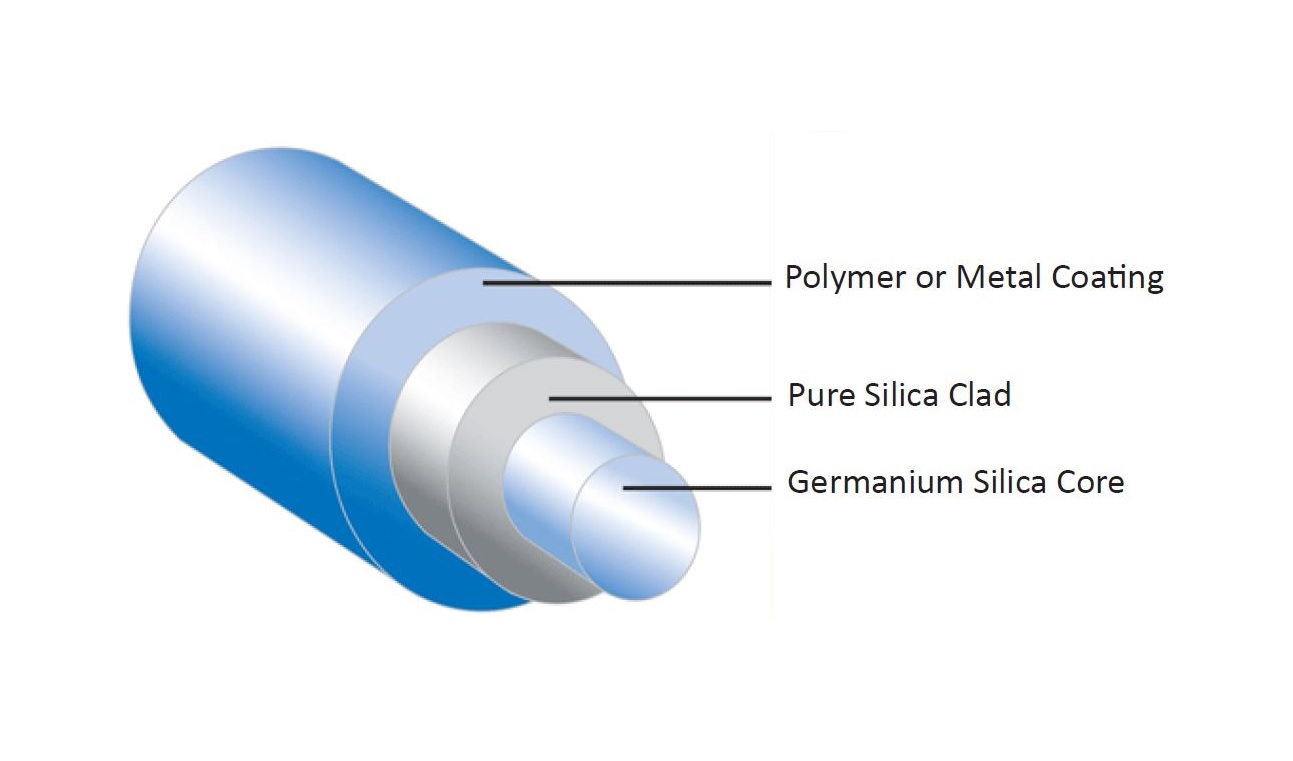

As an option, some of our multi mode fibers are also available in a metalized version. With these high-performance aluminium or gold coatings, the fibers work reliably even at extreme temperatures and withstand harsh environmental conditions.

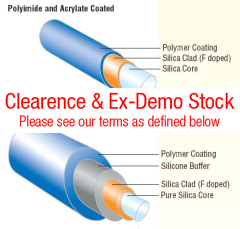

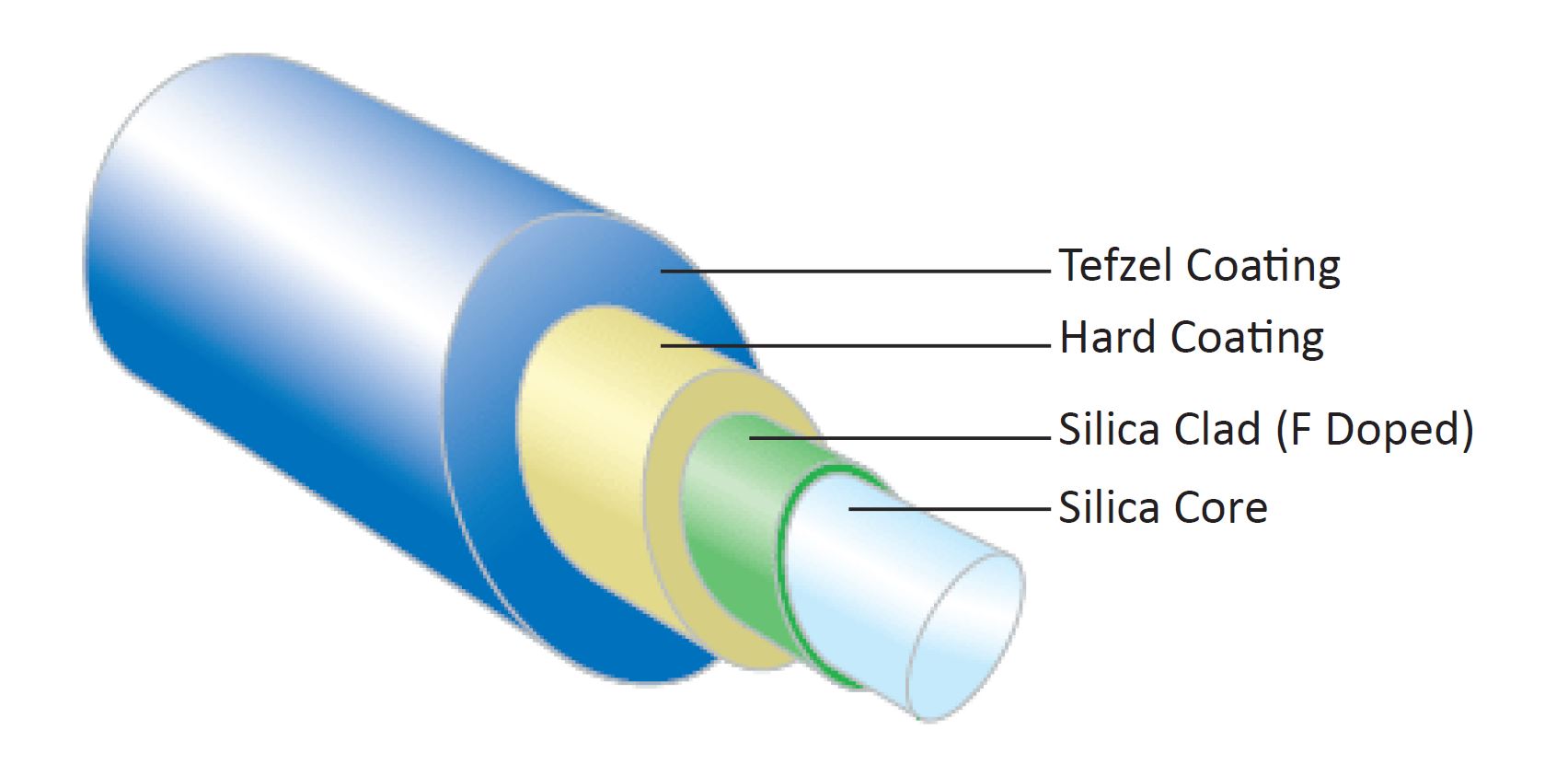

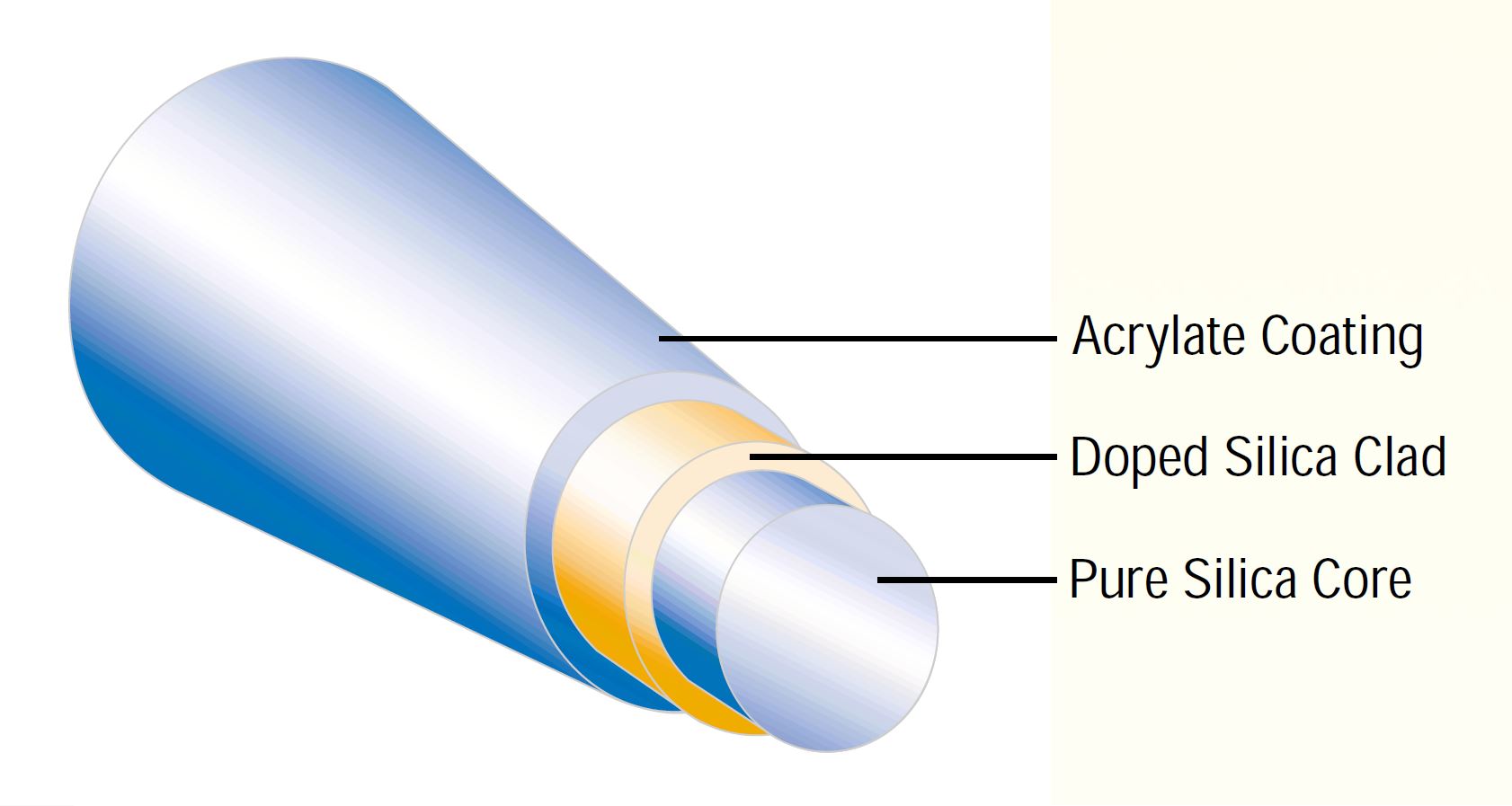

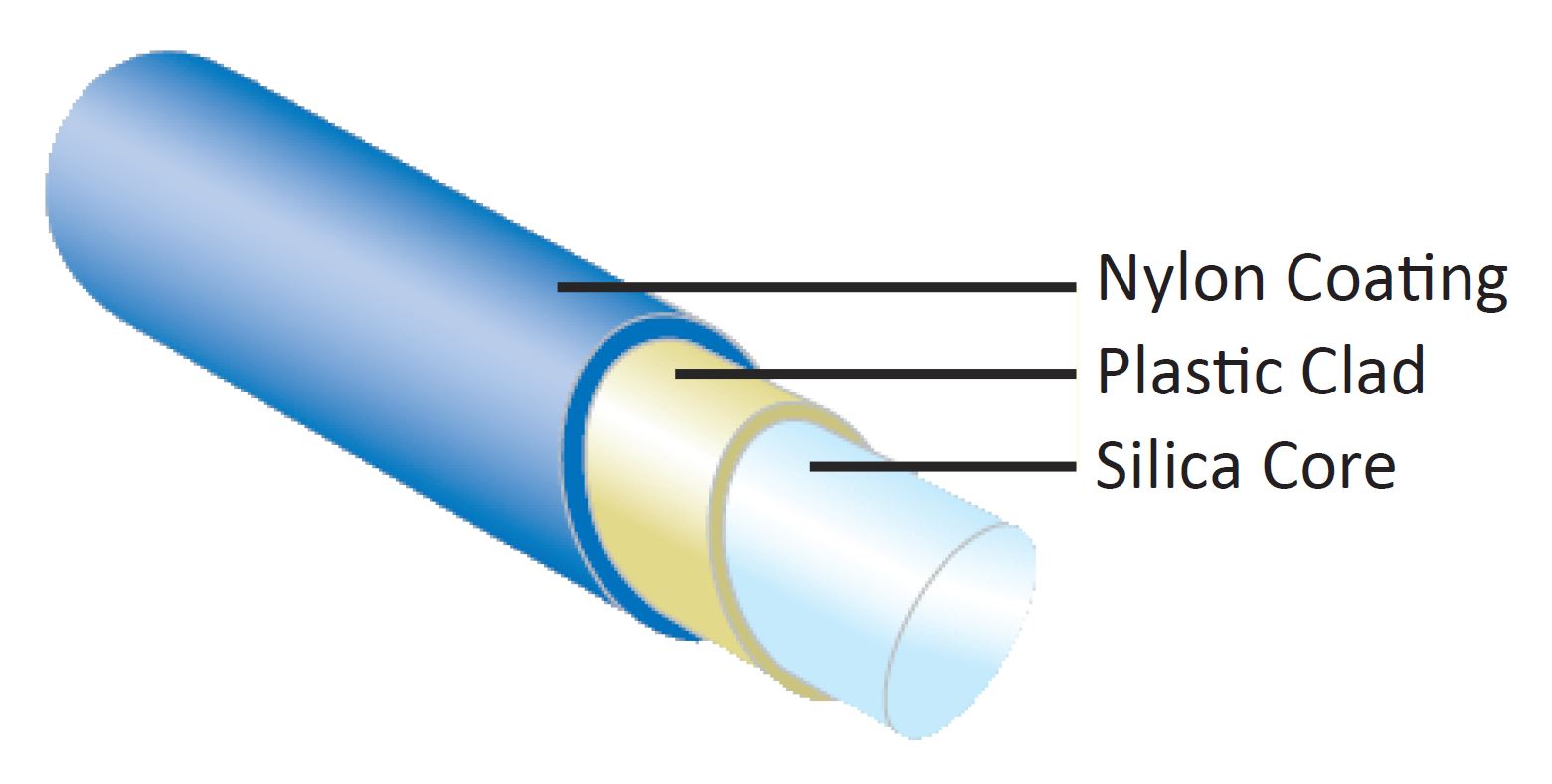

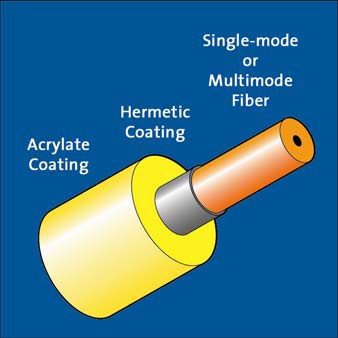

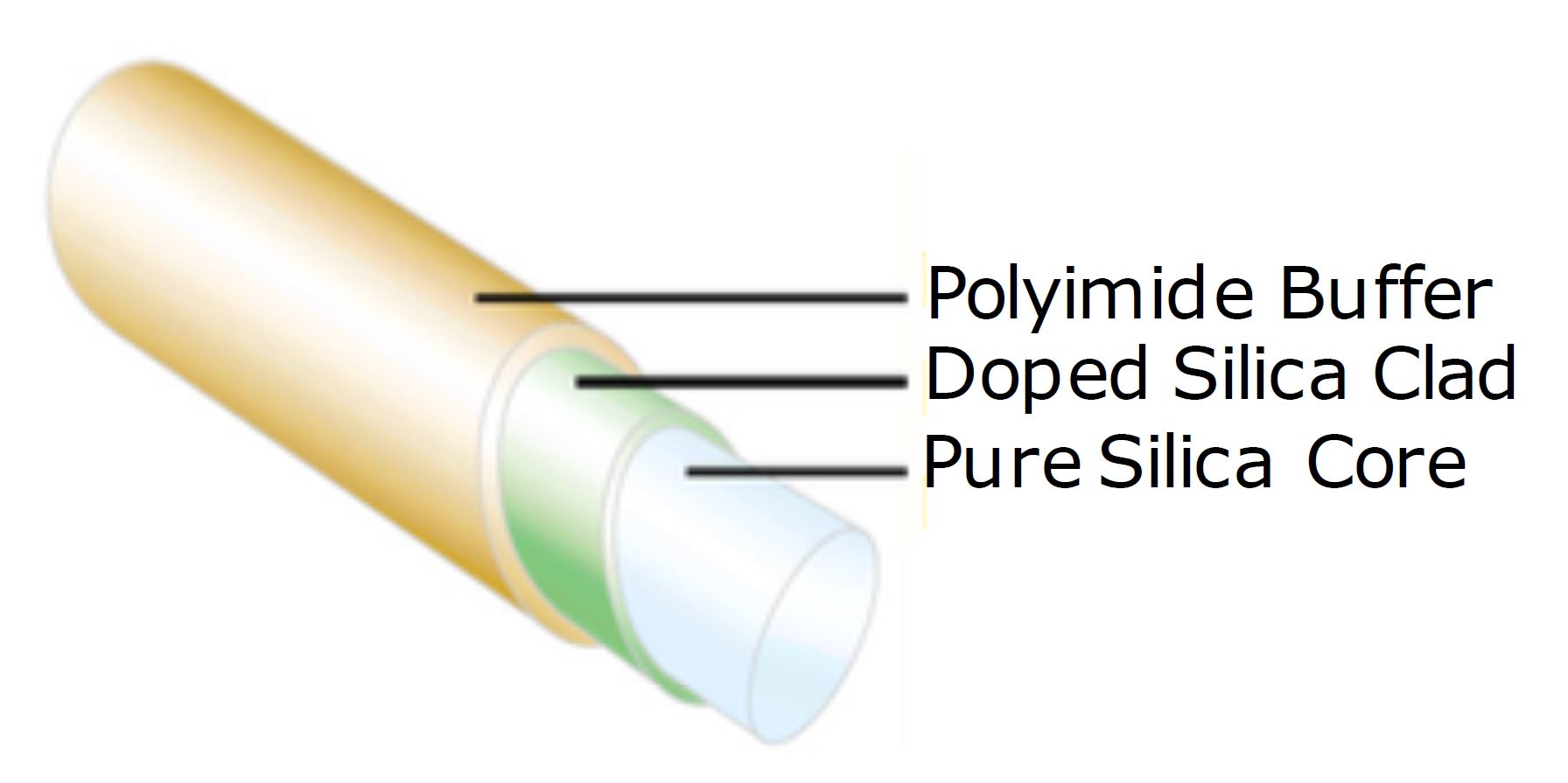

AMS Technologies’ portfolio also includes specialized graded index multi mode fibers, all silica fibers, MM fibers with polymer cladding, hard polymer cladding or hard polymer coating, as well as fibers with solarization-resistant or hermetic coatings.

Our offerings further include multi mode fibers for high optical powers, or for sensing systems operating in harsh environments, square core MM fibers providing “top hat” output intensity profiles, as well as tapered and/or lensed MM fibers. Some of the fibers can be equipped with anti-reflection technologies, enhancing transmission performance and increasing damage thresholds. In addition to common anti-reflection coatings, a technology based on nano-structures on the surface is available for selected fibers.

Related Products

Beyond multi mode fibers, our large portfolio of optical and specialty fibers for a wide wavelength range includes single mode (SM) fibers and polarization maintaining (PM) fibers as well as doped fibers or plastic optical fibers (POF).

Complementing our optical fiber offerings, AMS Technologies carries a large portfolio of fiber connectors, accompanied by a range of corresponding female mating sleeves and adapters. AMS Technologies can also offer an end-to-end solution for the assembly and test of fiber connectors that is exactly tailored to your requirements. In our broad portfolio you can find tools for stripping and cleaving your fibers, gluing and curing the fiber into the fiber connector using optical adhesives, polishing and cleaning of fiber optic end faces (especially important if the fiber is used with higher optical power), and finally testing your fiber connector with microscopes, interferometers as well as handheld and automated test equipment measuring return loss.

If you prefer pre-manufactured, ready to use fibers with the connectors already assembled to them, take a look at our range of SM, MM or PM patch cables. Shaped fiber tips or endcaps are further available options, improving the performance of the fiber-to-air interface, especially for high optical powers.

You need multiple fibers with or without connectors, manufactured, bundled and tested to your specifications? AMS Technologies has a proven track record of working with our OEM customers to design and build the most different configurations of bundled assemblies for a wide variety of photonics systems. Get in touch with the AMS Technologies optical fiber experts to discuss your customized fiber assembly or bundle that is tailored to meet your project’s specific requirements.

Definition

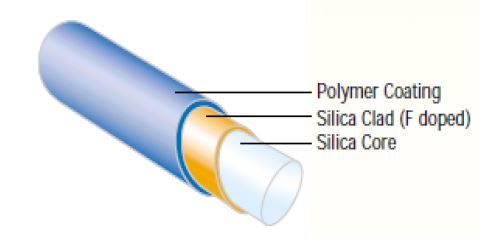

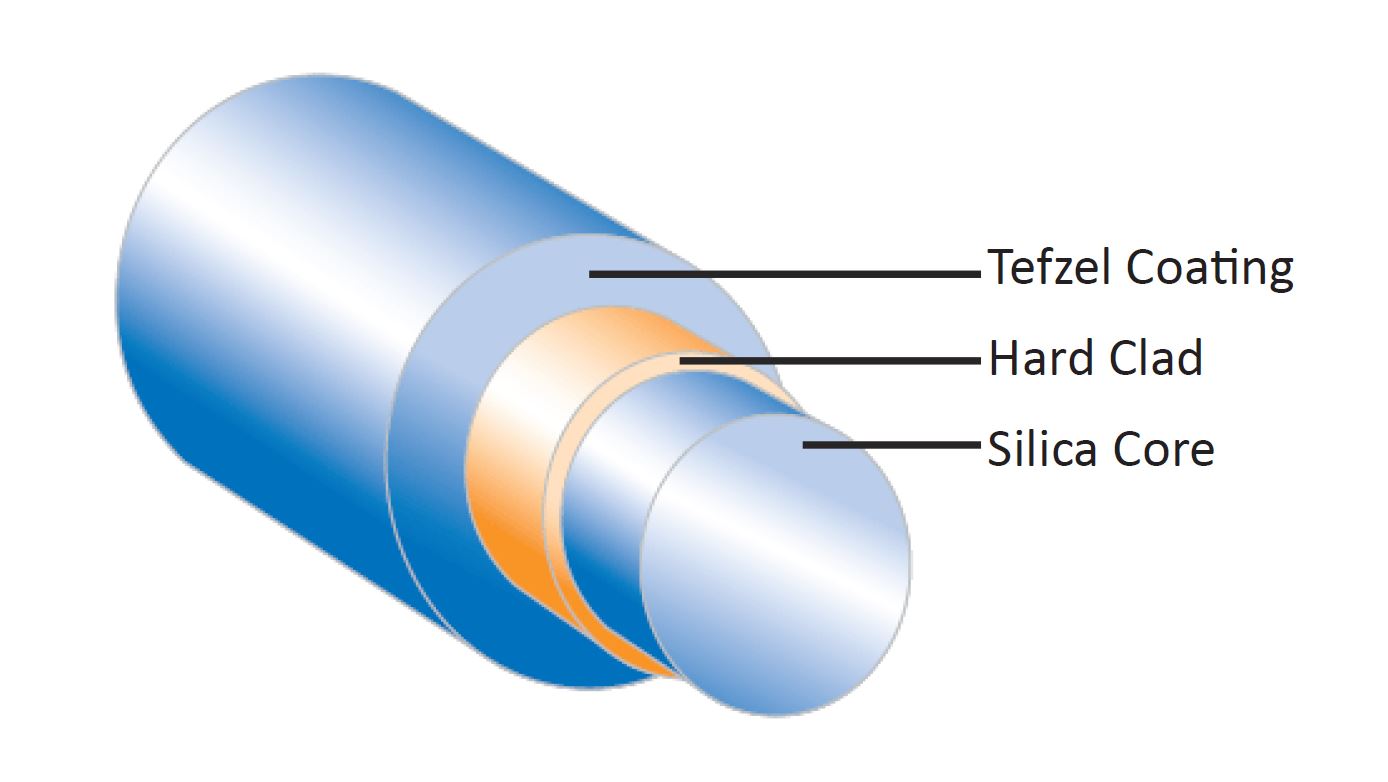

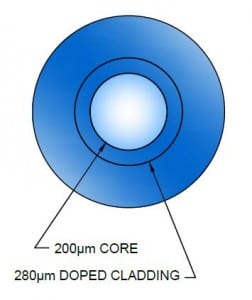

Optical or glass fibers can be used for many different applications, with the main purpose to transport light over a certain distance. Optical fibers consist mainly of a core with a certain diameter, a cladding, and a coating.

Multi mode optical fibers (MM fibers) are used for applications where it is important to transmit as much light as possible, mostly for illumination purposes. They feature relatively large core diameters, usually in the range of 50 µm up to 1,000 µm. Depending on the wavelength of the light, these diameters allow multiple modes of light to propagate through the fiber.

Due to interference effects, light pulses get distorted when travelling through a MM fiber over longer distances. To avoid this, single mode (SM) fibers or polarization maintaining (PM) fibers are used, especially for applications where the pulse character and shape of the optical signals is essential.

Multi mode fibers have a lot of advantages: Due to higher core diameters, the numerical apertures are higher, and more optical power can be transmitted. This results in easier coupling to different light sources like lamps, LEDs and lasers.

With regard to the distribution of their refractive indices, multi mode fibers can be divided into the two categories of step-index fibers and graded-index fibers:

Step-index Fibers

The core of a step-index fiber shows a uniform refractive index over its entire cross-section. At the boundary between the core and the cladding there is a sharp jump (step) in the refractive index, leading to total reflection of the light at that interface. This causes the light beam to repeatedly cross the axis of the fiber in a zigzag pattern. Due to path length differences, light beams entering the fiber from different angles have different times of travel through the fiber, which leads to modal dispersion or intermodal distortion for multiple modes of light. Therefore, step-index multi mode fibers are more suitable for low transmission speeds and short distances but have advantages in applications with high optical power density.

Graded-index Fibers

At the axis of a graded-index fiber’s core, the refractive index is high and gradually decreases in the core material towards the edge of the core where the value of the refractive index almost equals that of the cladding. Due to this continuous change in the refractive index, the light rays are deflected from the outer regions of the core towards the core axis. A graded-index fiber thus exhibits internal refraction of the light over the core’s cross-section instead of total reflection of the light at the core-cladding interface. As a result, graded-index multi mode fibers show properties such as a high bandwidth, low optical losses or higher bending tolerance. Modal dispersion is significantly reduced, and the graded-index multi mode fiber is thus suitable for transmitting optical signals over longer distances and/or at higher speeds.

To make multi mode fibers usable in harsh environments at higher temperatures, they can be metallized with aluminium or gold coatings according to the customer’s specification. An additional flexible metal tube can protect the fiber and offer more durability in industrial applications.

For enhanced transmission performance and increased damage thresholds, parts of our multi-mode fiber portfolio can be equipped with anti-reflection technologies. In addition to common anti-reflection coatings, a technology based on nano-structures on the surface is available for selected fibers.

Further options include to equip some of the fibers with a broad selection of shaped tips – standard configurations as well as custom designed shapes – or end-caps to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface.

Alternative Terms: Multi-Mode Optical Fiber; Multimode Fiber; MM Fiber; MMF; Multi Mode Fiber Optic Cable; Multimode Fiber Optic Cable; Glass Fiber