Tapered and Lensed Fibers

Tapered and Lensed Fibers Available From Stock

AMS Technologies carries a broad range of tapered and lensed single mode (SM) and polarization maintaining (PM) fibers with 125 µm cladding. By laser shaping the fiber end, the light can be transformed to improve mode matching and coupling efficiency with a waveguide device, laser diode chip or photodiode chip.

Make your choice of SM and PM tapered and lensed fibers with core diameters ranging from 4 µm to 9 µm. Using these tapered and lensed fibers, spot diameters between 2 µm and 6 µm can be achieved. The fibers are protected by an outer jacket with a diameter of 0.25 mm to 0.4 mm. Some models feature anti-reflective (AR) coating.

Product Portfolio

Our series of tapered and lensed fibers offers a convenient way to improve coupling between optical fibers and waveguide devices, laser diodes or photo diodes. Shaping the fiber end face to create the optimal light output/input for specific applications provides the best coupling efficiencies and mode matching abilities in a taper. While single mode (SM) and polarization maintaining (PM) tapered and lensed fibers are produced by laser shaping the fiber end, multi mode (MM) tapered and lensed fibers are polished versions with a polish radius and taper angle.

Shaped fiber tip assemblies are available in standard configurations like angled, ball, radiused, conical, chisel or diffuser tips, as well as custom designed shaped tip fiber assemblies for optimum control over beam delivery and/or increased efficiency of light collection. The shaped tips for a broad range of multi mode fibers are bare or encapsulated in a glass tube, to prevent fluids and other materials from impacting the shape of the light output from the fiber.

AMS Technologies offers a comprehensive series of tapered SM and MM fibers used for mode mixing, lowering optical power density in high power applications, and converting numerical aperture (NA) in optical power delivery applications. These tapered optical fibers are manufactured by very carefully controlling the drawing process to produce a single continuous fiber with an integral tapered section, resulting in superior fiber strength, alignment precision and optical power transmission. Additionally, they can be equipped on demand with a patented anti-reflective technology that enhances fiber transmission performance and significantly increases the damage threshold for your application over a large wavelength range.

Custom configurations of tapered and lensed fibers can be designed if required – get in touch with AMS Technologies for more information and to discuss your customized solution.

Related Products

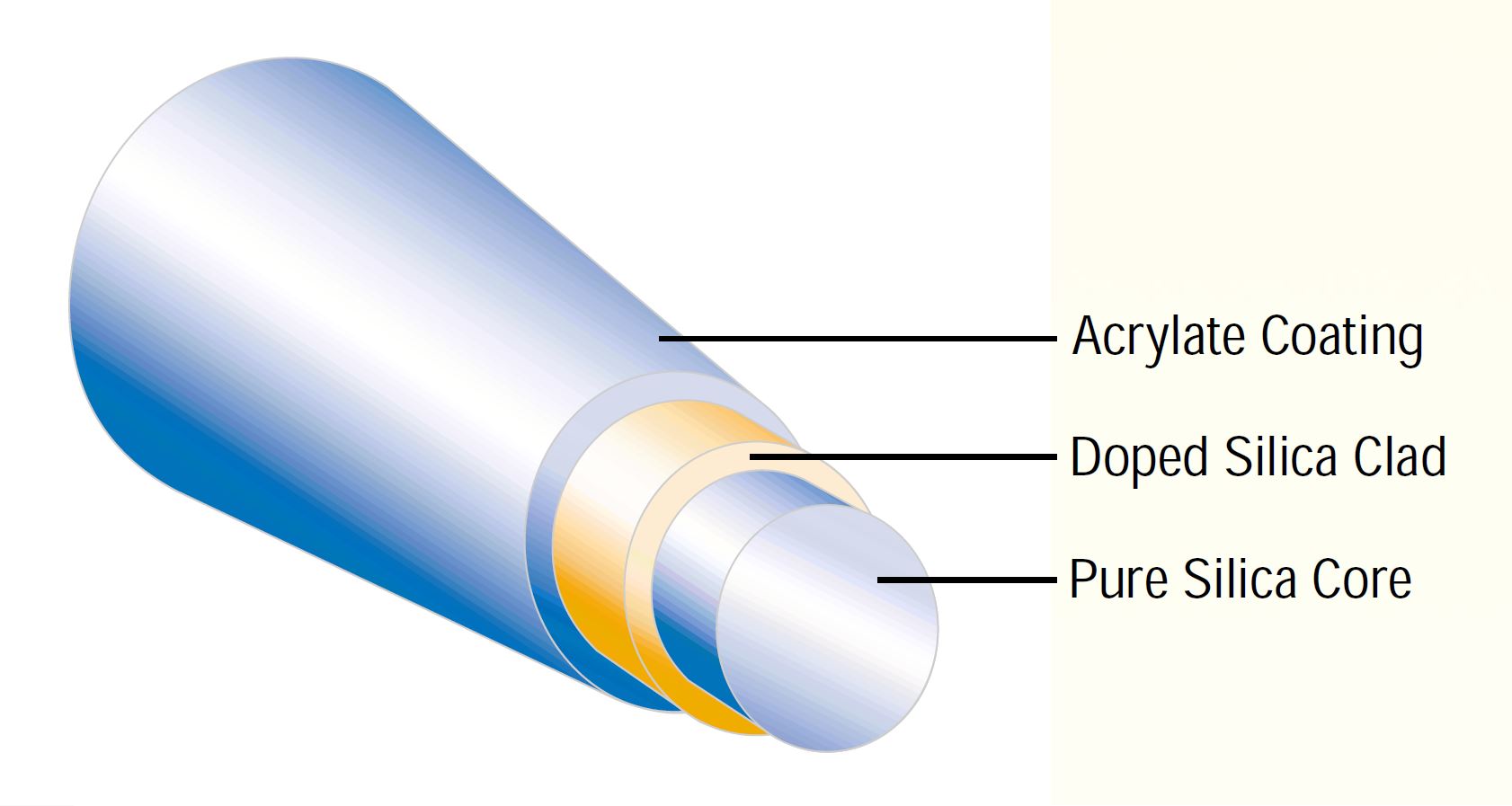

Our tapered and lensed fibers complement our broad range of optical and specialty fibers for a wide wavelength range, including single mode (SM) fibers, multi mode (MM) fibers, polarization maintaining (PM) fibers as well as doped fibers or plastic optical fibers (POF), but also patch cables, bundles and assemblies (including V-Groove assemblies). For driving light into tapered and lensed fibers, have a look at our various lasers and light sources.

Further fiber components are available like light to fiber couplers/collimators, fiber connectors, mating sleeves and adapters, fiber receptacle collimators and focusers, fiber WDMs, combiners, splitters and couplers, fiber amplifiers, attenuators and polarization controllers, as well as fiber optic circulators, delay lines, filters isolators and switches.

Our portfolio of precision optics includes optical lenses, optics assemblies, optical filters, optical prisms, optical mirrors, optical beamsplitters, etalons, optical gratings, optical isolators, and polarization optics as well as optical scanners and deflectors or optical modulators, q-switches and pockels cells.

For mounting, adjusting and moving our optical components with high precision, we carry an array of optomechanics and motion control such as optical mounts, rotary and translation stages plus motion controllers as well as optical tables, breadboards and platforms.

Definition

Tapered and lensed fibers are optical fibers whose end is changed in geometry and shape. By processing with a laser or mechanical polishing, a taper or/and a lens is created at the fiber’s end face, which transforms the outgoing light – usually focusing it on a circular or oval Gaussian spot – and thus leads to better coupling between the fiber and other optical components such as laser diodes, photodiodes, or waveguide devices.

With a laser, more complex geometries of the fiber end face can be created than by polishing. The process therefore allows more flexibility and enables the creation of an optimal output or input light beam with custom spot shapes and sizes for a wide variety of applications – for example, circular or oval spots with very small diameters. This allows tapers to be created that offer the best coupling efficiency and mode matching. Because laser processing can be fully automated, it offers cost advantages over polishing for high-volume production.

On the other hand, polishing the fiber tip to a specific angle and radius also leads to the formation of tapers providing an optical lens for circular spots – and oval spots can also be achieved with polishing, usually by working the fiber tip into a chisel or wedge shape. Compared to laser shaping, polishing leads to better centering of the resulting taper in relation to the cladding. This is important, for example, in applications where several adjacent tapers with very precise spacing between them are required – as in V-groove fiber arrays. Polished tapers are therefore preferable here, while laser shaped tapers are more suitable for single-fiber applications.

The beam quality in terms of the best possible matching of the bundled light spot to the characteristics of the waveguide plays a decisive role for high-quality coupling of laser diodes and waveguides. For the coupling of a photodiode to a fiber, on the other hand, a high beam quality is not required, the focused light spot just has to be smaller than the active area of the photodetector – therefore tapered fibers for photodiodes are usually available at lower costs.

Another type of tapered fiber has a taper not only at the fiber tip, but is manufactured by modulating the drawing process of a single mode or multi mode fiber to produce a smaller-diameter (tapered) area over a longer fiber section. A tapered optical fiber produced in this way provides optical mode mixing, which in turn makes the spatial distribution of optical power in the fiber more homogeneous. Thus, a larger cross-section at the fiber input can accommodate higher power laser energy without damage, while the smaller cross-section at the fiber output facilitates connection to a wide range of optical applications. This version of tapered fibers is used, for example, as an optical component that changes the numerical aperture in fiber applications or as a tool to compensate for different tolerances within an optical system.

Alternative Terms: Fiber Taper; Optical Fiber Taper; Shaped Fiber Tip