€78.73*

Content:

1 pcs

Available in 20 days, delivery time 1-2 days

Product number:

C003810-6

Manufacturer:

OZ Optics

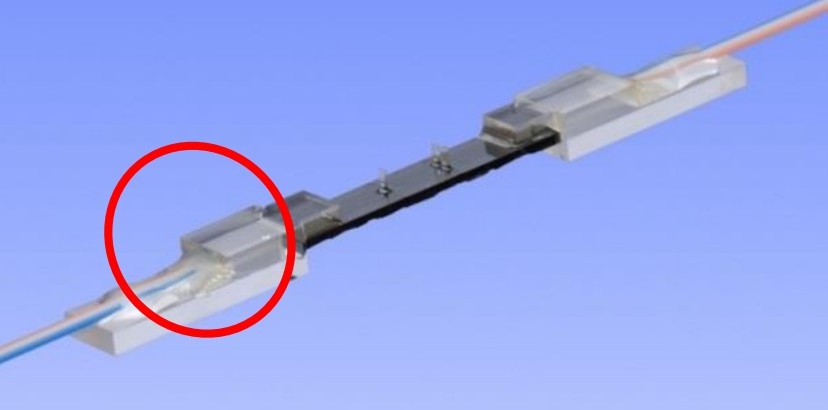

Product information "TSMJ-3A-1550-9/125-0.25-7-5-26-2 SM Tapered and Lensed Fiber"

SM Fiber; 1550 nm; 9/125 µm Fiber; FC/APC; 0.25 mm Jacket; 5 µm Spot Diameter; 26 µm Working Distance; 2 m Length; 7 mm Stripped Length

Manufacturer "OZ Optics"

Located in Canada's capital city of Ottawa and established in 1985, OZ Optics Ltd. is a leading worldwide supplier of fiberoptic products for existing and next-generation optical networks such as components and test equipment. Target markets include telecommunications, cable television, medical, military, industrial, aerospace, petrochemical and educational sectors. OZ Optics is ISO 9001:2000 and Telcordia certified.

Related links of the manufacturer