Plate to Air Thermal Management Assemblies

Product Portfolio

Plate to air thermal management assemblies like our mini direct cooling thermoelectric kit available from stock are the ideal solution for photonics cooling when a solid-state heat source like a laser diode needs to be cooled and temperature-stabilized by a compact and maintenance-free cooling device.

Driven either by thermoelectric (Peltier) elements or direct evaporation of a refrigerant compressor circuit, our series of mDC-KITs cools and stabilizes the laser mounting plate to a set temperature. Heat from the laser source and from the cooling engine (Peltier respectively compressor) is dissipated “directly” to the air – there is no water circuit that requires maintenance, occupies space and bears risk of corrosion.

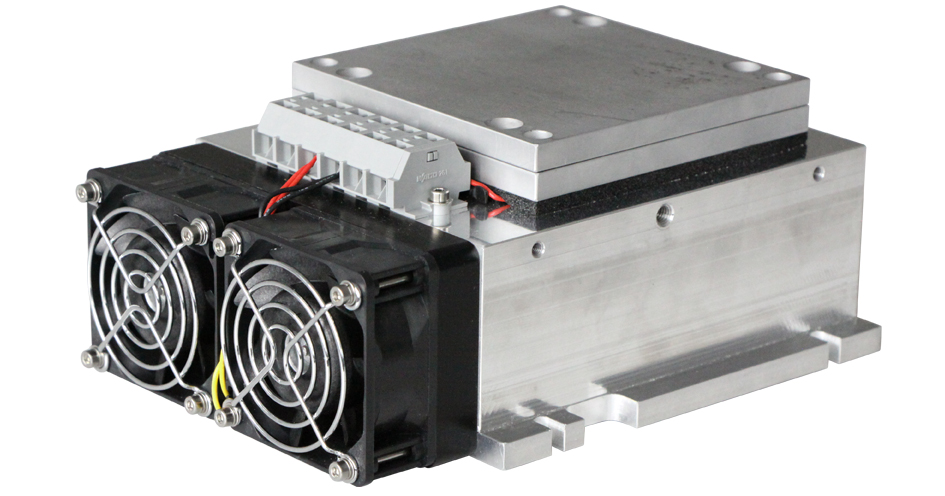

mDC-T-KITs – mini direct cooling thermoelectric kits

Our mDC-T-KITs mini direct cooling thermoelectric kits come with a 108 x 108 mm mounting plate that can be worked on, i.e. individual mounting patterns can be drilled by the customer himself. The kits’ Peltier modules can be configured for either 12 or 24 VDC power supply. Depending on cooling requirements, the 60 x 60 mm fans’ speed can be reduced for quiet operation. Our thermoelectric mini direct cooling kit available from stock provides a nominal 130 W of cooling capacity.

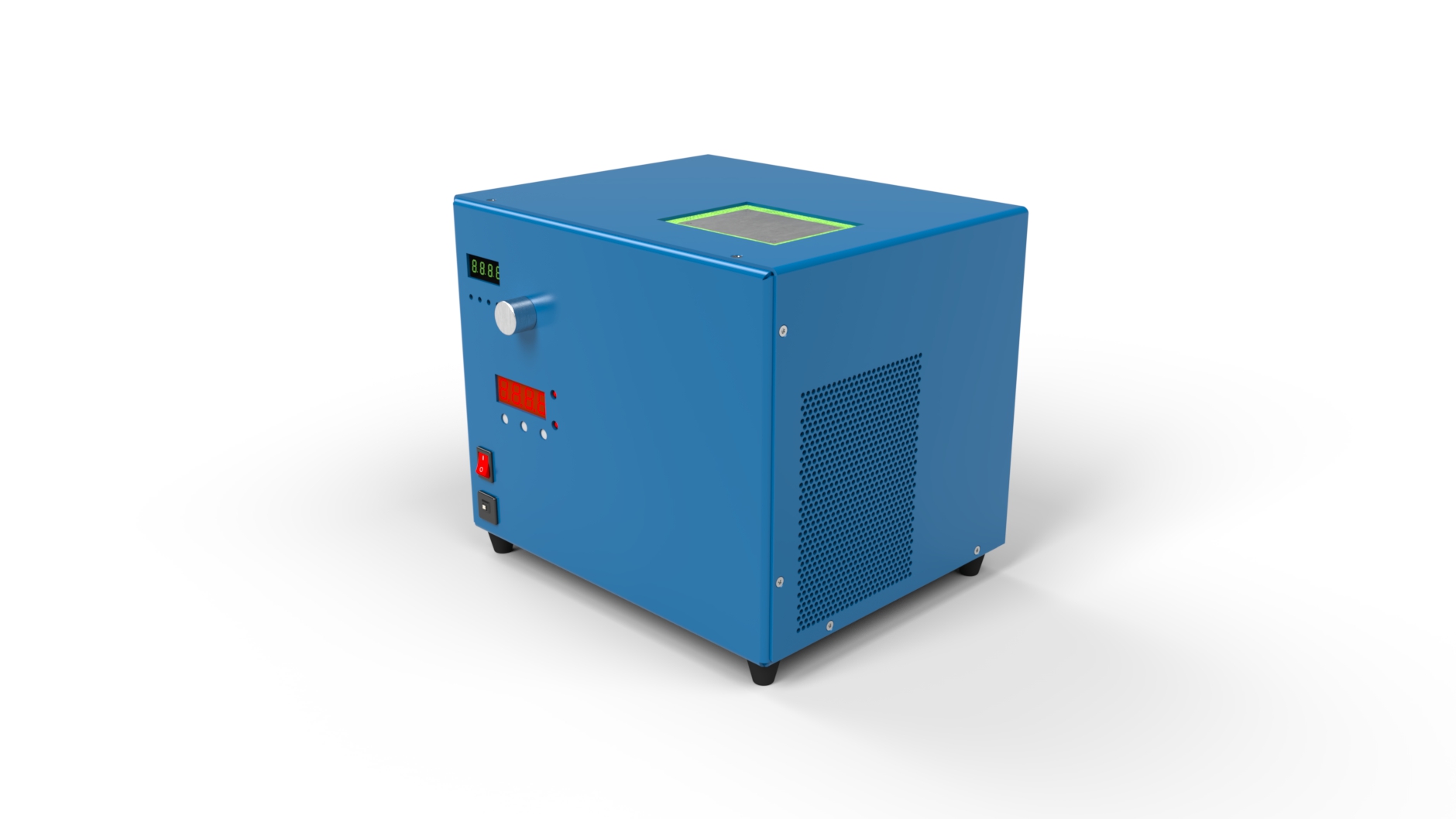

mDC-C-KITs - mini direct cooling compressor kits

Our mDC-C-KITs mini direct cooling compressor kits can be configured for 100 to 700 W of maximum cooling capacity and replace recirculating chillers in applications where a compact and maintenance-free cooling device is required. The laser mounting plate can be a customized evaporator plate for highest efficiency reaching COP values of up to 5, or a mounting plate that can be worked on, i.e. individual mounting patterns can be drilled by the customer himself. Our refrigerant circuits are carefully designed and allow for a robust control behavior. When lasers are switched ON or OFF, overshoot and undershoot typically do not exceed ±1 K. Temperature stability in continuous operation is ±0.1 K. The set temperature range is from +15 to +25°C. Currently R134a is used as refrigerant which is inert, non-toxic and non-inflammable. R600a – isobutane – would also be available. The compressors are inverter driven, with a power supply of either 240 VAC, 120 VAC or 12 VDC.

mDC-CT-KITs - mini direct cooling compressor/thermoelectric kits

Our mDC-CT-KITs mini direct cooling kits are based on compressors cascaded with thermoelectric coolers, allowing for very large plate temperature ranges. Using our mDC-CT-4-KIT, thermal management designers can evaluate the technology. Based on the "direct evaporation" technology, the compressed refrigerant evaporates directly on the hot side of the thermoelectric (Peltier) module and thus dissipates the heat very effectively and with high heat flux.

The Compressor/ Peltier cascade significantly expands the temperature range of the capabilities of the individual technologies, enabling a very wide operating temperature range from -50°C to +150°C in a compact device. Utilizing suitable insulation, constant operation at -50°C is possible, while still providing about 4 W cooling power at this extreme temperature point.

Possible applications are in the fields of analytics, molecular reactors, rheology, or viscosity measurement – or wherever very low temperatures have to be maintained with moderate heat loads.

We have many years of experience in the development and design of customized plate to air thermal management assemblies that can be specified according to the requirements of your application. Contact us to discuss your customized solution!

Our series of thermoelectric power generators is a quite unusual application of plate-to-air thermal management, as these devices produce electrical power based on a heat difference between the plate side of the system thermally connected to a solid-state heat source and the ambient air.

Related Products

Complementing the plate to air technologies, AMS Technologies also carries liquid to air thermal management assemblies like our range of recirculating chillers, ambient cooling systems and other liquid to air thermal management solutions, using water or water-glycol mixtures for heat transfer. For lower thermal loads, air-to-air thermal management assemblies like our range of cabinet coolers and dehumidifiers are the ideal solution to remove heat from cabinets and enclosures. And for very high thermal loads like large power electronics or energy storage systems, our liquid to liquid thermal management assemblies allow efficient heat transfer to process water.

You are looking for components rather than complete thermal management solutions? AMS Technologies provides a broad range of air cooling components including heat sinks as well as fans for forced air cooling. Thermoelectric components like thermoelectric (Peltier) modules or TEC temperature controllers are also available. Additionally, we provide extensive development services of TEC-based solutions for a variety of applications.

Definition

Plate to air thermal management assemblies are designed for transferring heat as efficient and direct as possible from a thermally conductive plate, on which heat sources such as laser diodes or power electronics are mounted, to the ambient air. AMS Technologies concentrates on plate to air thermal management solutions that do not require a liquid circuit as an intermediate heat carrier. Thermoelectric elements or compressor-driven vapor compression circuits are used as heat pumps, which absorb the heat directly at the plate and release it to the ambient air either via a combination of heat sink and fan or via a fan-assisted condenser (fin heat exchanger).