Filter

–

OpTek Systems

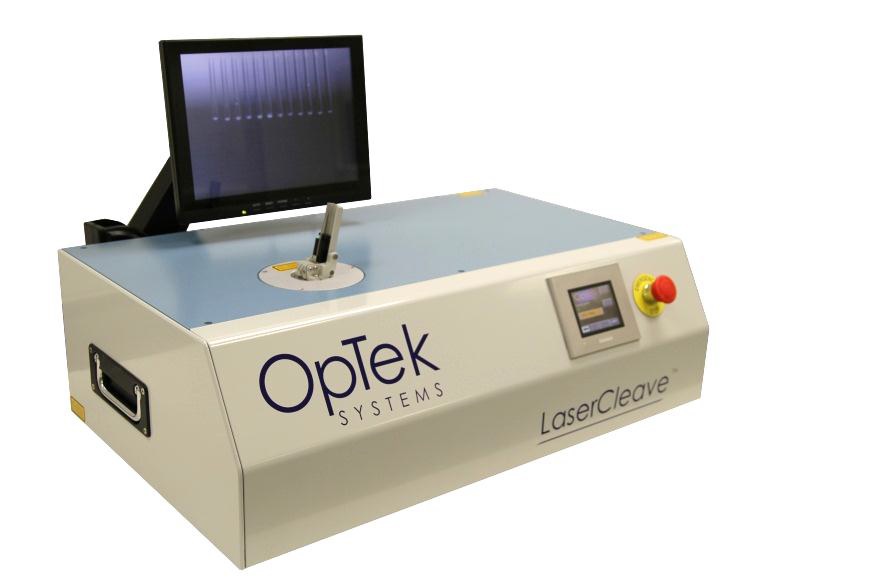

LaserCleave™-1500 Laser Cleavers

Power Supply Single Phase, 1.7 kVA; Air Cooled; Integrated Viewing Cameras; Dimensions 756x505x245 mm; Weight 35 kg

OpTek Systems’ LaserCleave™-1500 series are tabletop fiber processing tools for optical interconnect production.

Within this series, two versions are available:

LaserCleave™-1500 for single- and multi-fiber connectors

LaserCleave™-1500 LT for LightTurn and MXC connectors

Engineered to address the production of existing and a new generation of optical interconnects in a compact and user friendly platform, LaserCleave™ systems are designed to maximise productivity in connector manufacture.

LaserCleave™ production tools from OpTek Systems are built around the technology that has been relied on in performance critical, volume production of optical fiber components since the mid 1990’s. OpTek’s unique machine tools are in service around the world producing laser-processed fiber ends of unmatched quality and reproducibility, with many millions of OpTek-processed ends in service in telecoms, datacoms, medical, aerospace and defence applications.

Key Features:

Interchangeable Fixture for a Wide Range of Connector Types

Rapid, Non-contact Process

Cuts Fiber and Epoxy Close to Pedestal

Accurate and Repeatable Cut-off Length or Cleave Position

Control Over Fiber End Geometry

No Core-cracks, Chipping, Scratching or Hackle

Minimize or Eliminate Post Cleaving Operations

Reduced Overall Cost of Terminations

Electrical Supply: Single Phase, 1.7 kVA

Cooling: Air Cooled, Water Cooling Option

Vision: Integrated Viewing Cameras

Shards: Capacity Collection >1M Fiber Shards

Dimensions: 756 x 505 x 245 mm

Weight: 35 kg

Applications: Production of Optical Interconnects; Maximise Productivity in Connector Manufacture; Production of Optical Fiber Components; Telecoms; Datacoms; Medical; Aerospace; Defence

Product number:

SW11365

Manufacturer:

OpTek Systems

LaserCleave™-3500 Laser Cleaver

Power Supply 220 VAC, 20 A, Single Phase; Fully Integrated; Cassette Loading; Dimensions 1,400x800x1,200 mm; Weight 350 kg

OpTek Systems’ LaserCleave™-3500 laser cleaver has been developed to address the challenges faced in the production of OE connectors, AOC’s (Active Optical Cables) and other connectors requiring optical grade cleaves.

LaserCleave™-3500 is a fully integrated, standalone tool for laser cleaving of optical interconnect assemblies. The tool is cassette loaded to provide automated processing of multiple assemblies, with interchangeable cassettes for processing of both connectorized and bare-fiber components.

LaserCleave™-3500 is designed to be operator independent and has all necessary ancillary services on-board, with the exception of the electrical supply.

OpTek’s unique machine tools are in service around the world producing laser-processed fiber ends of unmatched quality and reproducibility, with many millions of OpTek-processed ends in service in telecoms, datacoms, medical, aerospace and defence applications.

Key Features:

Accurate Cleaving of Protruding Fiber After Assembly in the Connector

LaserCleave™ Laser Cleaving for Exceptional Quality and Reproducibility

Cassette Loading for Multi Part Processing

Interchangeable Cassettes for Maximum Flexibility

Fully Integrated for Standalone “Turn-key” Operation

CE Marked and Certified

Electrical Supply: 220 VAC, 20 A, Single Phase

Shards: Integrated Collection of >1M Fiber Shards

Communications: PC Remote Control Via Internet

Dimensions: 1,400 x 800 x 1,200 mm

Weight: 350 kg

Applications: Laser Cleaving of Optical Interconnect Assemblies; Standalone “Turn-key” Operation; Maximise Productivity in Connector Manufacture; Production of Optical Fiber Components; Telecoms; Datacoms; Medical; Aerospace; Defence

Product number:

SW11366

Manufacturer:

OpTek Systems

LaserCleave™-Lens/Wedge Laser Lensers

Power Supply Single Phase, 20 A; Lens Type Spherical, Aspheric, Wedge, Bi-conic, Angled Wedge, Angled Bi-conic; Process Speed 10, 20 s; Tip Radius 5->200 µm; Dimensions 1,430x830x1,180 mm; Weight 450 kg

OpTek Systems’ LaserCleave™-Lens/Wedge laser lensing tools offer unparalleled performance in the production of lensed optical fiber.

Processing of polarization maintaining (PM), single mode (SM) and multi mode (MM) fiber is fast, accurate and reliable, with processing times at a fraction of that required for grind and polish, and first-pass yield at 99.9%. Spherical, aspheric and asymmetric lenses are laser-machined for high-efficiency coupling, improving your product performance while reducing manufacturing costs.

OpTek’s laser lensing tools are available in two versions:

LaserCleave™-Lens conical lenser for spherical & aspheric lenses

LaserCleave™-Wedge wedge/bi-conic lenser for asymmetric lenses

OpTek LaserCleave™-Lens/Wedge laser lensing systems machine a high-performance lens directly onto the end of an optical fiber. Asymmetric lenses are produced using feedback from on-line far field measurements to ensure accurate centring of the lens on the fiber core.

The non-contact process is incredibly fast and uses on-line imaging to ensure accurate centration of the lens to the fiber. The superior optical quality of the surface and exceptional control over the lens ensures maximum coupling.

Key Features:

Lens Type: Spherical, Aspheric, Wedge, Bi-conic, Angled Wedge, Angled Bi-conic

Scrap Angle Removal

Process Speed: Typically 10, 20 s Per Lens

Flexibility: Store and Recall Thousands of Lens Designs

Change Time Between Different Lenses: 10 s

Tip “Radius” LaserCleave™-Lens: 5 to 15 μm SM, to >200 μm MM & Collimator

Tip “Radius” LaserCleave™-Wedge: 5 to 50 μm SM & MM

Tip “Radius” Tolerance: ±0.5 μm SM

Lens Alignment to Core: ±0.5 μm SM

Yield: >99%

Surface Finish: Laser Polished

Lens Performance: Superior Surface Finish and Ability to Tune Lens Design Gives Un-matched Optical Performance

Robust Rounded Edges

Non-contact Process

Power Supply: Single Phase, 20 A

No Water or Gas Needed

Vision: Integrated High-magnification Vision System

Shards: Integrated Collection of >1M Fiber Shards

Communications: PC Remote Control Via Internet

Dimensions: 1,430 x 830 x 1,180 mm

Weight: 450 kg

Applications: Production of Lensed Optical Fiber; Laser-machining a High-performance Lens Directly onto the End of an Optical Fiber

Product number:

SW11367

Manufacturer:

OpTek Systems

LaserStrip-1500 Fiber Stripper

Single-Fiber Window-Stripping; Strip Length ≤ 30 mm; Processing Time < 1min/fiber

OpTek Systems offers tabletop fiber processing tools tailored for optical component production. The LaserStrip production tools are centered around technology that has been proven effective in the high-performance, high-volume production of optical fiber components since the mid-1990s. These tools are engineered to cater to both existing and emerging generations of components, all within a compact and user-friendly platform. LaserStrip™ is specifically designed to optimize productivity in manufacturing.Utilizing a contact-free process, laser stripping of optical fibers is employed for the precise removal of acrylate buffers. This system is configured for single-fiber window-stripping with strip lengths of up to 30mm, ensuring precise dimensional control. With the elimination of blades and any potential for glass abrasions, this process is particularly well-suited for ultra-high reliability (UHR) applications.

Key features:

Rapid, non-contact processing

Accurate and repeatable feature positioning

Eco-friendly manufacturing (chemical free)

Improve performance, increase yield, reduce manufacturing costs

Reliability due to the elimination of blades and glass abrasions

Ideal for ultra-high reliability (UHR) applications

Accurate and repeatable strip length with clean and well-defined shoulder

High-throughput - processing time is less than 1 minute/fiber including load and unload operations

Product number:

SW11970

Manufacturer:

OpTek Systems

LaserStrip-1500R Fiber Stripper

Integrated Viewing Camera; Window Strip Length 1-50mm, End Strip Length 1-15mm, Strip Length Tolerance ±0.2mm, Shoulder Transitions <500µm

OpTek Systems' LaserStrip production tools incorporate technology that has been integral to the high-performance, large-scale production of optical fiber components since the mid-1990s. These tools are meticulously engineered to cater to both existing and emerging generations of components, with a primary focus on maximizing productivity within a user-friendly platform.The LaserStrip system employs a contact-free laser-stripping process to remove acrylate buffers from optical fibers. Configurable for up to 16-fiber ribbons, it accommodates window strip lengths of up to 50 mm and end strip lengths of up to 15 mm, all with precise dimensional control. Notably, the elimination of blades and any potential for glass abrasions renders this process exceptionally well-suited for ultra-high reliability (UHR) applications.

Key features:

Rapid, non-contact processing

Accurate and repeatable feature positioning

Eco-friendly manufacturing (chemical free)

Improve performance, increase yield, reduce manufacturing costs

Reliability due to the elimination of blades and glass abrasions

Ideal process for ultra-high reliability (UHR) applications

Accurate and repeatable strip length with clean and well-defined shoulder

High-throughput – less than 1 minute/ribbon including load and unload time

Ability for customer to modify strip length, scan speed, laser pulse repetition rate and duty cycle through integrated control panel

Class 1 enclosure with provisions for customer tooling used to hold fiber during processing

Fiber Compatibility: 12-Fiber 125µm Ribbon Acrylate Coated (16 Fiber Ribbon solutions available)

Product number:

SW11973

Manufacturer:

OpTek Systems

OpTek Systems with facilities in Europe, Asia and the USA is a global supplier of production line equipment and sub-contract laser processing services for a wide range of precision laser micromachining applications. OpTek has experience in an extensive range of applications in electronics, telecommunications, semiconductor, pharmaceutical, automotive, aerospace, oil and gas, biomedical and consumer sectors. The company provides solutions for R&D and small scale production through to fully automated high volume production, specialising in the development of novel laser micromachining processes and the transitioning of these for highly productive routine manufacturing. Examples include OpTek’s patented fiber processing technology LaserCleave, providing stripping, lensing and cleaving of optical fiber and optical interconnects. This technology is widely adopted for applications in broadband telecommunications, datacom, sensing, medical and fiber laser production.