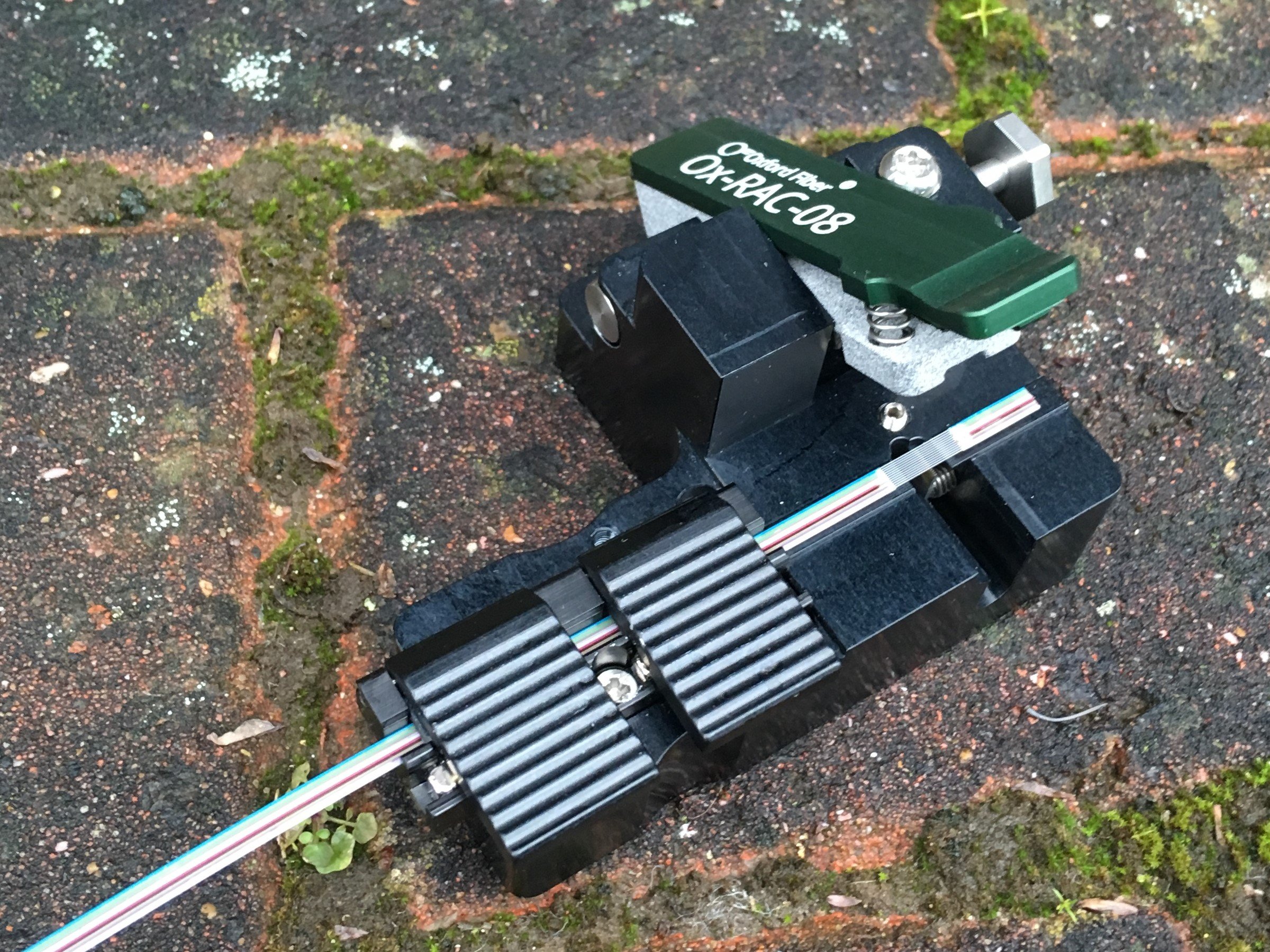

Product information "LaserStrip-1500R Fiber Stripper"

Integrated Viewing Camera; Window Strip Length 1-50mm, End Strip Length 1-15mm, Strip Length Tolerance ±0.2mm, Shoulder Transitions <500µm

OpTek Systems' LaserStrip production tools incorporate technology that has been integral to the high-performance, large-scale production of optical fiber components since the mid-1990s. These tools are meticulously engineered to cater to both existing and emerging generations of components, with a primary focus on maximizing productivity within a user-friendly platform.

The LaserStrip system employs a contact-free laser-stripping process to remove acrylate buffers from optical fibers. Configurable for up to 16-fiber ribbons, it accommodates window strip lengths of up to 50 mm and end strip lengths of up to 15 mm, all with precise dimensional control. Notably, the elimination of blades and any potential for glass abrasions renders this process exceptionally well-suited for ultra-high reliability (UHR) applications.

Key features:

- Rapid, non-contact processing

- Accurate and repeatable feature positioning

- Eco-friendly manufacturing (chemical free)

- Improve performance, increase yield, reduce manufacturing costs

- Reliability due to the elimination of blades and glass abrasions

- Ideal process for ultra-high reliability (UHR) applications

- Accurate and repeatable strip length with clean and well-defined shoulder

- High-throughput – less than 1 minute/ribbon including load and unload time

- Ability for customer to modify strip length, scan speed, laser pulse repetition rate and duty cycle through integrated control panel

- Class 1 enclosure with provisions for customer tooling used to hold fiber during processing

- Fiber Compatibility: 12-Fiber 125µm Ribbon Acrylate Coated (16 Fiber Ribbon solutions available)