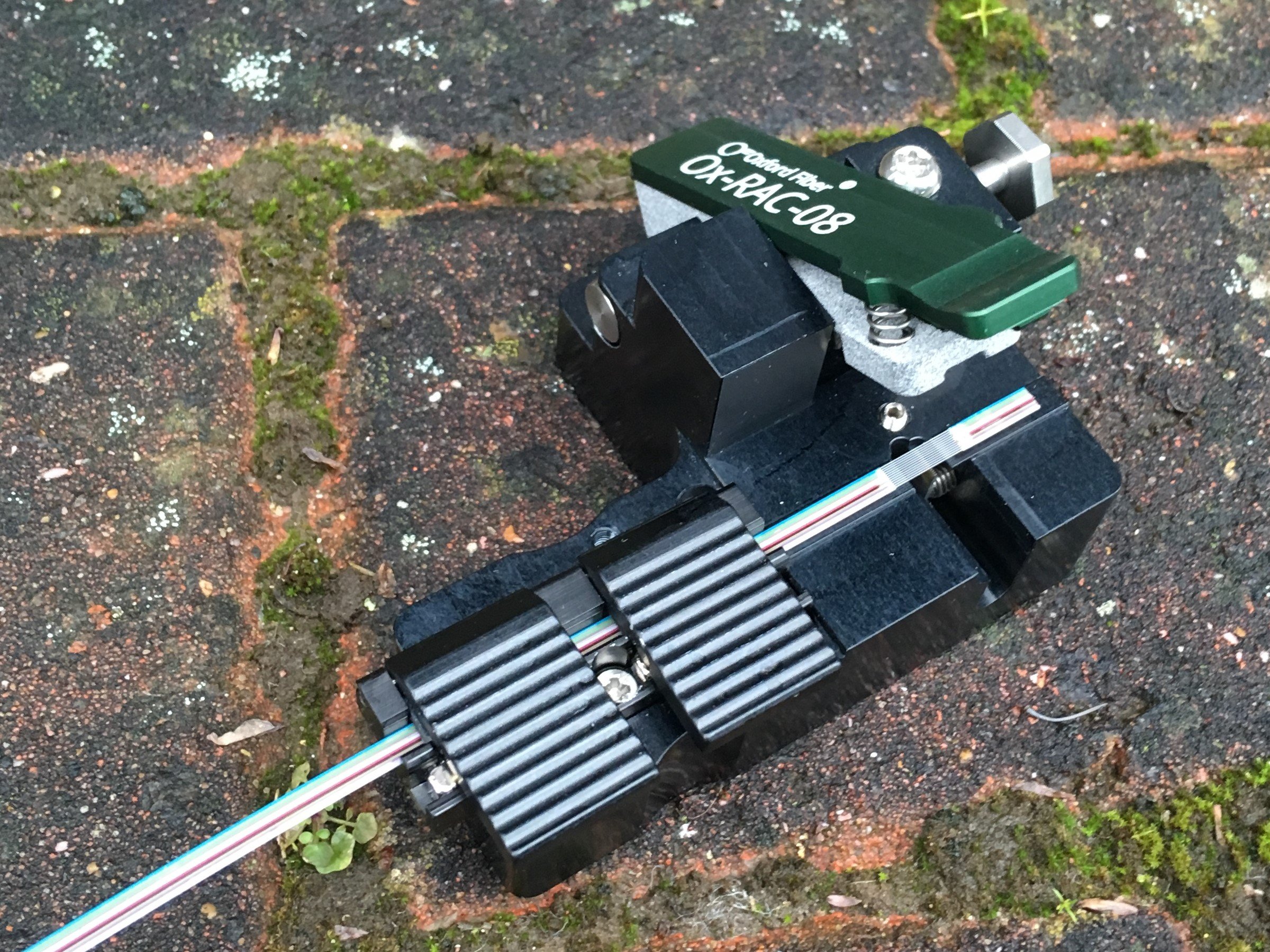

Product information "Ox-RAC-08 Angled Ribbon Fiber Cleaver"

Manual Angled Cleaving of Ribbon Fiber; Fiber Type SM Ribbon Fiber; Fibers in Ribbon 1-12; Fiber Diameter 125 µm; Cleave Angle 8° (±2°); Cleave Length 8-13 mm

Oxford Fiber’s Ox-RAC-08 is the right tool for angled cleaving of multiple optial fibers in a ribbon. This ability is truly unique and of great use to customers who want to connect optical fibers to planar optical waveguides such as lasers, detectors and splitters. The device’s cleave angle of 8° (±2°) is highly repeatable. The single mode (SM) ribbon fiber is clamped at two points and bent down onto a sharp diamond blade.

The optical fiber is cleaved so that its single mode core is at an angle of 8° from perpendicular so that the back-reflection is reduced. If you require a cleaver for any other fiber type or a custom cleaver tailored to your specifications, please get in touch with the AMS Technologies fiber cleaving experts.

Key Features:

- Staple Action for Easy Use

- Rugged Construction for Field Use

- 3.5mm Diamond Blade for Extended Life, Replaceable Blades

- Integrated Offset Bin

- Benchtop and Handheld Operation

- Easy Fiber Loading Using Custom Holder or “Oxford” Holder

- Compatible With Ribbon Mechanical Splice and MPO Connectors

- Fiber Diameter: 125 μm (SM, Single Mode Fiber)

- Fibers in Ribbon: 1 to 12

- Cleave Length: 8 mm to 13 mm (Set by Holder)

- Cleave Length Variation: 1 ±20 μm in Ribbon

- Cleave Angle: 8° (±2°)

- Blade Life: >2000 Ribbons Cleaved (Blade Replaceable)

- Dimensions (max): 67 mm x 40 mm x 79 mm long

- Weight: 250 g

Applications: Pigtailing Fiber Ribbons to Opto-electronic Devices such as Laser Arrays, Detector Arrays and Planar Waveguides