€59.20*

Available in 10 days, delivery time 1-2 days

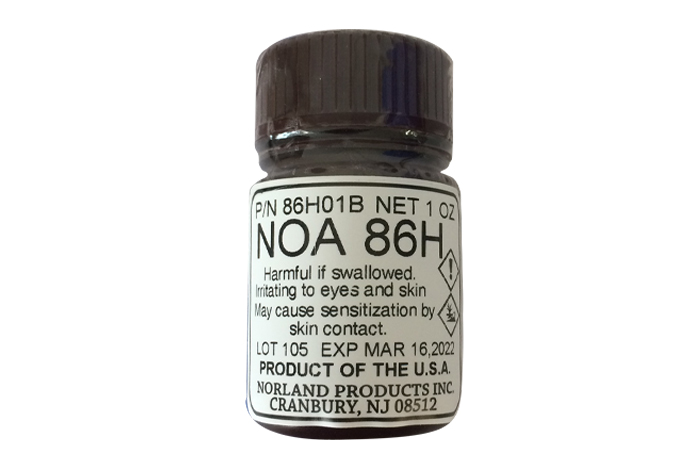

Product information "NOA 88 Optical Adhesive 1oz bottle"

Refractive Index 1.56; 250 cps Viscosity at 25°C

Norland Optical Adhesive 88 ("NOA 88") is an optically clear, liquid adhesive that will cure when exposed to long wavelength ultraviolet light. The adhesive is a one-part, 100% solids material that offers advantages in optical bonding applications. The use of NOA 88 eliminates premixing, drying, or heat curing operations common to other adhesive systems. Curing time can be regulated by the end user by varying the intensity of the curing source.

NOA 88 was formulated as a low outgassing (CVCM) and low Total Mass Loss (TML) adhesive. The ideal applications for this adhesive is for coating of parts destined for space exploration, bonding of high tech computer components,adhering parts in very sensitive instruments and coating sensitive components.

NOA 88 is cured by ultraviolet light (315 nm to 395nm) with maximum sensitivity at 365 nanometers. The adhesive requires 5 Joules/sq.cm of energy to fully cure a 25 to 50 micron bond. The material has low oxygen inhibition, so adhesive exposed to air will cure tack-free with sufficient exposure to UV light.

Typical Properties of NOA 88

| Solids | 100% |

| Refractive Index of Monomer | 1.52 |

| Elongation at Failure | 41% |

| Modulus of Elasticity (psi) | 131,000 |

| Tensile Strength (psi) | 2,000 |

| Hardness - Shore D | 90 |

| Total Mass Loss (TML) | 1.07% |

| Collected Volatile Condensable Material (CVCM) | <0.01% |

| Dielectric Constant (1 MHz) | 4.06 |

| Dielectric Strength (V/mil) | 457 |

| Dissipation Factor (1 MHz) | 0.0341 |

| Volume Resistivity (ohm-cm) | 6.85 x 10 to the 14 power |

| Surface Resistivity (MEgohms) | 3.71 x 10 to the 12 power |

The shelf life of the liquid material is at least four months from the shipment date if kept in a cool (5-22° C) dark place in the original container. If refrigerated, allow the adhesive to come to room temperature prior to use.