€59.20*

Available in 10 days, delivery time 1-2 days

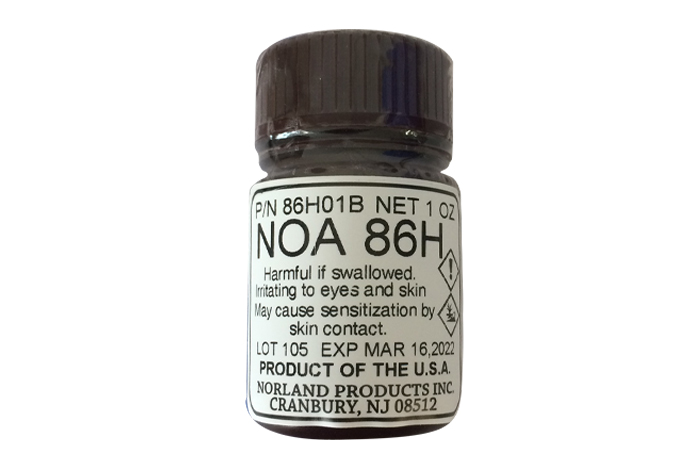

Product information "NOA 87 Optical Adhesive 1oz bottle"

Refractive Index 1.52; Viscosity at 25°C 900-1500 cps

Norland Optical Adhesive 87 is an optically clear one component, solventless, liquid adhesive that will cure when exposed to long wavelength ultraviolet and/or visible light. This adhesive is formulated to meet the Bellcore specification of 85°C/85RH for 2000 hours.

NOA 87 is recommended for bonding glass or plastics. This adhesive can be cured by ultraviolet light between 315 and 400 nanometers and visible light between 400 and 420nm. The peak absorption wavelengths are 325, 365 and 400nm. Minor absorption wavelengths are 410, 420nm. Full cure requires 3.5 Joules/cm2 of UV or visible energy.

Typical Properties of NOA 87

| Color | Slight yellow tint that disappears upon curing |

| Modulus of Elasticity (psi) | 209,700 |

| Tensile Strength (psi) | 4,880 |

| Elongation at Failure | 13% |

| Hardness - Shore D | 50 |

Keep NOA 87 in a cool (5-22°C) dark place. If refrigerated, allow the adhesive to come to room temperature before using.