Polarization Maintaining Fibers

Polarization Maintaining Fibers available from Stock

Our range of PANDA-type polarization maintaining (PM) optical fibers available from stock is suitable for applications where maintaining the light’s polarization over the length of the fiber is key.

These fibers feature extremely high birefringence, excellent polarization maintaining properties and low attenuation. PM fibers are available with coating outer diameters of 245 µm or 400 µm, suitable for transmission of light with operating wavelengths of 1300 nm or 1550 nm.

Product Portfolio

AMS Technologies’ portfolio also includes many more PANDA-type PM fiber products for operating wavelengths ranging from 410 nm to 1550 nm and with a variety of coating designs. In addition to standard versions, these PANDA PM fibers are also available with special features like bend insensitivity, high numerical aperture, thermally-diffused expanded core, reduced cladding, or are optimized for the RGB visible wavelength band.

As an option, some of our polarization maintaining fibers can be tapered and lensed or metallized with high-performance gold coatings, allowing the fibers to work reliably even at extreme temperatures and to withstand harsh environmental conditions.

Some of the fibers can be equipped with anti-reflection technologies, enhancing transmission performance and increasing damage thresholds. In addition to common anti-reflection coatings, a technology based on nano-structures on the surface is available for selected fibers.

Related Products

Beyond poralization maintaining fibers, our large portfolio of optical and specialty fibers for a wide wavelength range includes single mode (SM) fibers and multi mode (MM) fibers as well as doped fibers or plastic optical fibers (POF).

Complementing our optical fiber offerings, AMS Technologies carries a large portfolio of fiber connectors, accompanied by a range of corresponding female mating sleeves and adapters. AMS Technologies can also offer an end-to-end solution for the assembly and test of fiber connectors that is exactly tailored to your requirements. In our broad portfolio you can find tools for stripping and cleaving your fibers, gluing and curing the fiber into the fiber connector using optical adhesives, polishing and cleaning of fiber optic end faces (especially important if the fiber is used with higher optical power), and finally testing your fiber connector with microscopes, interferometers as well as handheld and automated test equipment measuring return loss.

If you prefer pre-manufactured, ready to use fibers with the connectors already assembled to them, take a look at our range of SM, MM or PM patch cables. Shaped fiber tips or endcaps are further available options, improving the performance of the fiber-to-air interface, especially for high optical powers.

You need multiple fibers with or without connectors, manufactured, bundled and tested to your specifications? AMS Technologies has a proven track record of working with our OEM customers to design and build the most different configurations of bundled assemblies for a wide variety of photonics systems. Get in touch with the AMS Technologies optical fiber experts to discuss your customized fiber assembly or bundle that is tailored to meet your project’s specific requirements.

Definition

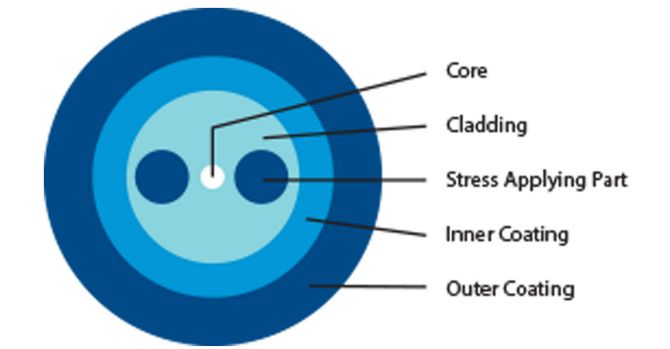

Optical or glass fibers can be used for many different applications, with the main purpose to transport light over a certain distance. Optical fibers consist mainly of a core with a certain diameter, a cladding and a coating.

In any ordinary optical fiber, tiny imperfections cause random changes to the polarity of light propagating through the fiber. For some applications where maintaining the light’s polarization is key, a polarization maintaining fiber (PMF or PM fiber) is used. In most versions of this single-mode specialty fiber, tension rods are integrated into the fiber’s cladding on opposite sides of the core, inducing a strong but tightly controlled birefringence. If linearly polarized light is properly launched into a PM fiber it maintains its linear polarization during propagation.

Most common PM fiber types are defined by the shape and position of the stress rods. The cross-section of a PANDA-PM fiber resembles the face of a panda bear with the typical dark circles around the bear’s eyes, while the cross-section of a Bow-Tie PM fiber with its stress rods in the shape of a trapezoidal prism looks like a bow tie. Both PM fiber types are interchangeable for most applications.

To make polarization maintaining fibers usable in harsh environments at higher temperatures, they can be metallized with aluminium or gold coatings according to the customer’s specification. An additional flexible metal tube can protect the fiber and offer more durability in industrial applications.

For enhanced transmission performance and increased damage thresholds, parts of our polarization maintaining fiber portfolio can be equipped with anti-reflection technologies. In addition to common anti-reflection coatings, a technology based on nano-structures on the surface is available for selected fibers.

Further options include to equip some of the fibers with a broad selection of shaped tips – standard configurations as well as custom designed shapes – or end-caps to achieve higher coupled power into a fiber core by reducing the power density at the air / silica interface.

Alternative Terms: Polarization Maintaining Optical Fiber; PM Fiber; PMF; Polarization Maintaining Fiber Optic Cable; PM Fiber Optic Cable; Panda Fiber; Bow-tie Fiber; Glass Fiber