Linear, Rotation and Tilt Stages

Product Portfolio

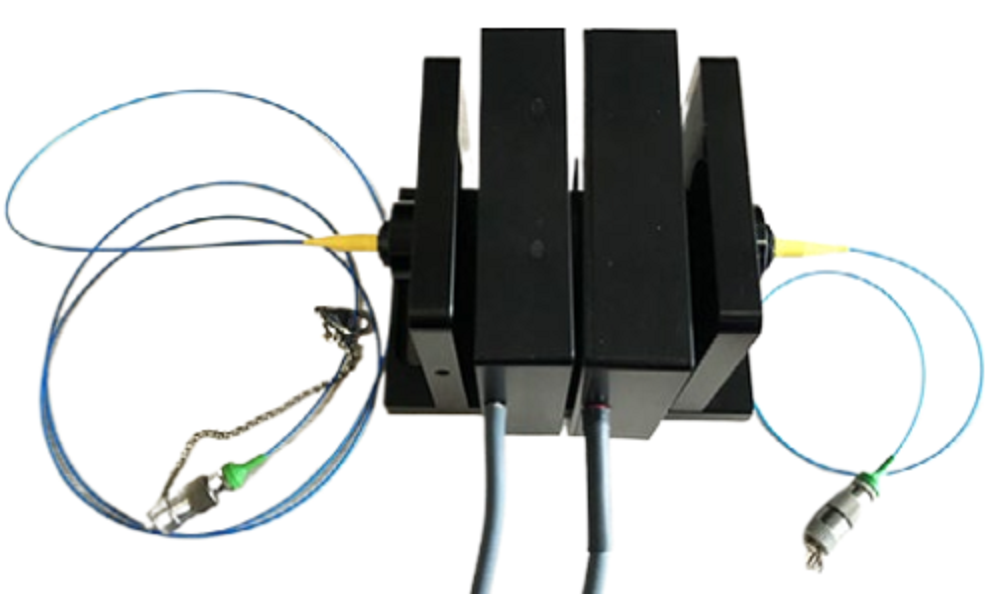

We provide a series of translation stages that has been designed for multiple applications. Within this series, linear stages are available as well as angular or tilted linear and rotary stages – including “lab jacks”. The three different types of stages - dovetail slide, ball bearing and crossed roller - have characteristics which dictate their application.

By maintaining both external and mounting dimensions in common increments, multi-axis systems (XY or XYZ) with various travel ranges can be constructed, and a multi-axis device can be assembled using the positioning mechanism best suited to each axis.

Our translation stages can easily be incorporated into other systems. And, since many of these manual or motorized stages can be actuated by several different methods, one has the choice of precision within the same assembly.

A family of specialized single-axis linear stages has been created by splitting the two-axis design into a modular design that is useful where only one axis for tilt is required. Several tapped holes provide variable mounting opportunities and can be accessed from front, edge, top and bottom for attachment. These mounts are manufactured from one solid piece of either spring steel or aluminium and allow low-stiction fine adjustments.

Many of our linear, rotation and tilt stages may be modified for vacuum compatibility or configured with custom mounting holes or features to fit your specific application. Please get in touch with the AMS Technologies optomechanics experts to discuss your customized translation stage solution.

Related Products

The main purpose of our linear, rotation and tilt stages is to support, hold and move high-precision optical components – available from AMS Technologies in a very broad spectrum, ranging from optical lenses, optical assemblies, optical windows, prisms, beamsplitters or optical filters to fiber collimators and focusers, and also lasers and light sources.

Additionally, we carry a broad range of complementary products such as motion controllers, optical mounts, optical tables, as well as a broad range of optical test and measurement equipment.

Definition

Stages are critical components of motion control systems. They enable the exact movement or guidance of an object around or along one axis (X or Y or Z) or more axes (XY or XYZ) in space. Depending on the drive, manual and motorized stages are available, the latter featuring different types of mostly electric motors, allowing motorized and even automatized adjustment in one or more axes.

Linear Stages

Linear stages restrict the movement of an object mounted to them to one axis of movement, allowing only this one degree of freedom. They consist of a mechanically fixed component, the base, and a platform that moves against that base. Both parts are connected by a linear guide or bearing, so that the platform can only be moved linearly relative to the base.

There are different types of such a guide, each with specific advantages and disadvantages – and thus each suitable for different applications:

- Dovetail guides are the simplest type, provide the largest bearing area and thus allow the highest load, are very shock resistant, can theoretically cover unlimited travel and promise a long service life. However, they require high forces for movement and can easily bind when bent; moreover, the friction varies with the adjustment speed.

- Ball bearings allow rolling rather than sliding motion, permit unlimited travel and are relatively inexpensive. However, due to the point load transfer of the bearing balls, these bearings cannot support heavy loads, are sensitive to mechanical shocks and contamination by foreign bodies, exhibit high wear, and the positioning load oscillates during bearing recirculation.

- Due to the larger contact surface of the rollers used compared to balls, crossed roller bearings offer the advantages of ball bearings, plus a higher load capacity and greater rigidity, but also at a higher cost due to increased manufacturing effort.

Rotating Stages

Rotating stages are ideal solutions for rotating optics and other mechanical components around one or more axes. Rotating stages are almost exclusively based on ball bearings.

Lab Jacks

Lab jacks are useful tools for positioning optical elements in laboratories with their optical axis at the desired height. In addition to miniature versions for small travel, versions are also available for positioning larger and heavier objects or assemblies.

Alternative Terms: Translation Stage; Linear Slide; Lab Jack